Ks0428 keyestudio Mini Tank Robot V2

Thanks for your support on our products, we will continue to provide you better quality and service!

*About keyestudio

Keyestudio is a best-selling brand owned by KEYES Corporation, our product lines range from controller boards, shields and sensor modules to smart car and complete starter kits for Arduino, Raspberry Pi and BBC micro:bit, which designed for customers of any level to learn electronics and programming knowledge. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

You can obtain the details and the latest information through visiting the following web sites:http://www.keyestudio.com

*References and After-sales Service

1.Download Profile:https://fs.keyestudio.com/KS0428

2.Feel free to contact us please, if there is missing part or you encounter some troubles. Welcome to send email to us:service@keyestudio.com.

We will update projects and products continuously based on your sincere advice.

*Warning

1.This product contains tiny parts(screws, copper pillars), keep it out of reach of children under 7 years old please.

2. This product contains conductive parts (control board and electronic module). Please operate according to the requirements of this tutorial. Improper operation may cause overheating and damage parts. Do not touch and immediately disconnect the circuit power.

*Copyright

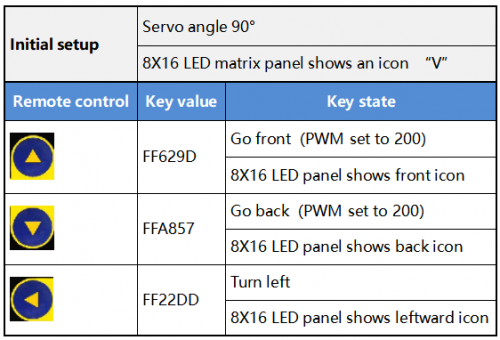

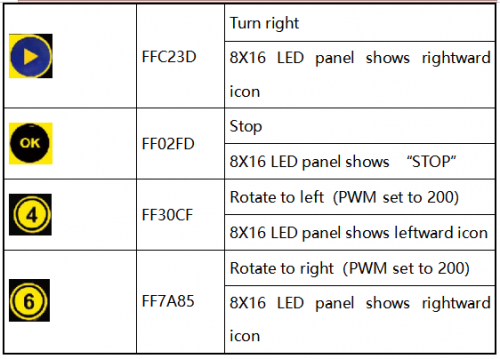

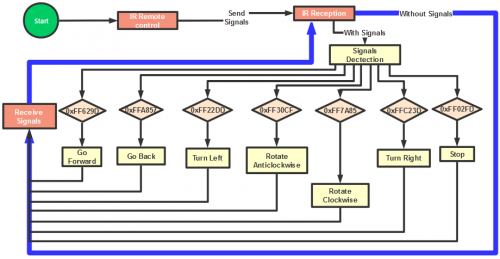

The keyestudio trademark and logo are the copyright of KEYES DIY ROBOT co.,LTD. All products under keyestudio brand can’t be copied, sold and resold without authorization by anyone or company. If you’re interested in our items, please contact to our sales representatives: fennie@keyestudio.com

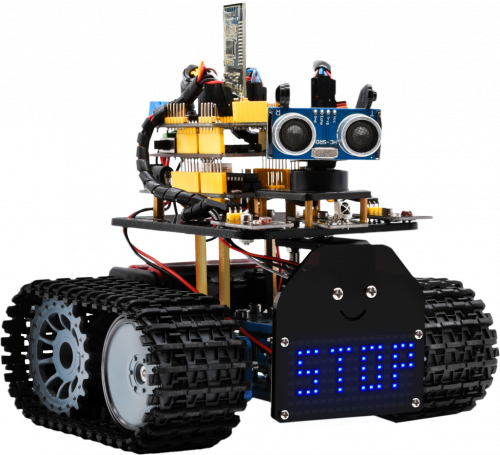

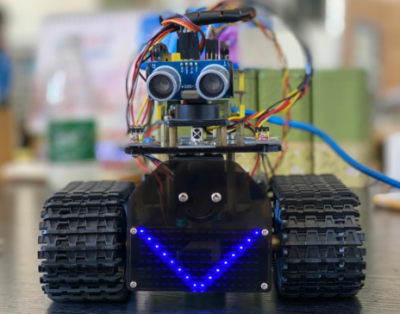

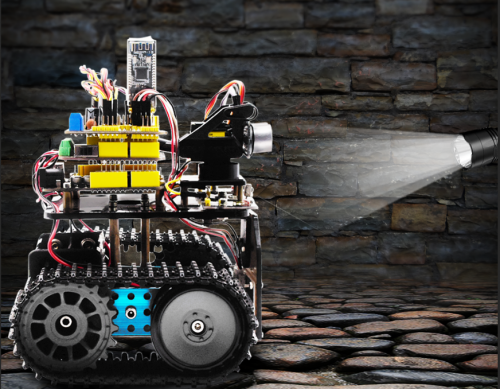

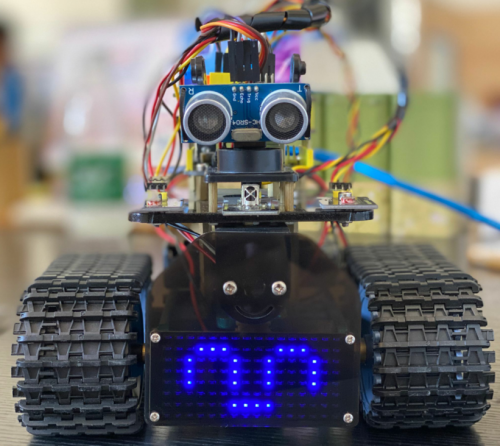

Introduction

Nowadays, technological education such as VR, kids programming, and artificial intelligence, has become mainstream in educational industry. Thereby, people attach importance to STEAM education. Arduino is pretty notable in Maker education.

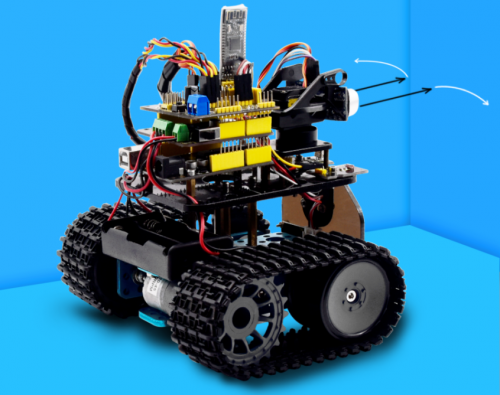

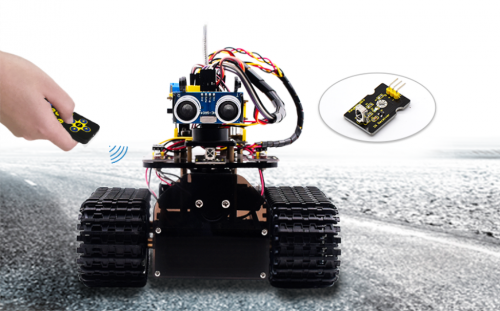

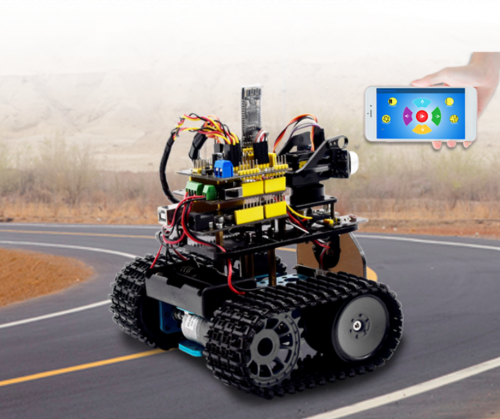

So what is Arduino? Arduino is an open-source electronics platform based on easy-to-use hardware and software. Arduino boards are able to read inputs - light on a sensor, a finger on a button, or a Twitter message - and turn it into an output - activating a motor, turning on an LED, publishing something online. Based on this, Keyestudio team has designed a mini tank robot. The tank robot has a processor which is programmable using the Arduino IDE, to mapped its pins to sensors and actuators by a shield that plug in the processor, it reads sensors and controls the actuators and decides how to operate.

15 learning projects, from simple to complex, will guide you how to make a smart tank robot on you own and introduce the detailed knowledge about sensors and modules.

Simultaneously, it is the best choice if you intend to obtain a DIY robot for learning programming, entertainment and competition requirement.

Features

1.Multi-purpose: Obstacle avoidance, follow, IR remote control, Bluetooth control, light following, ultrasonic follow and displayed face emoticons.

2.Simple assembly: No soldering circuit required, complete assembly easily.

3. High Tenacity:Aluminum alloy bracket, metal motors, high quality wheels and tracks.

4. High extension: expand other sensors and modules through motor driver shield and sensor shield

5. Multiple controls: IR remote control, App control(IOS and Android system)

6.Basic programming:C language code of Arduino IDE.

Specification

- Working voltage: 5v

- Input voltage: 7-12V

- Maximum output current: 2A

- Maximum power dissipation: 25W (T=75℃)

- Motor speed: 5V 200 rpm/min

- Motor drive mode: dual H bridge drive (L298P)

- Ultrasonic induction angle: <15 degrees

- Ultrasonic detection distance: 2cm-400cm

- Infrared remote control distance: 10 meters (measured)

- Bluetooth remote control distance: 50 meters (measured)

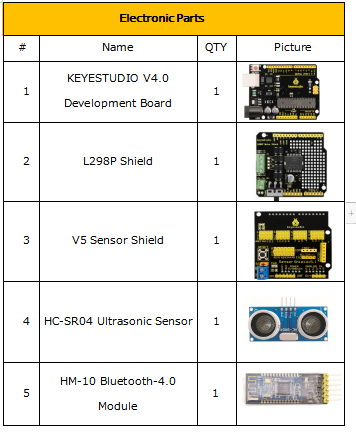

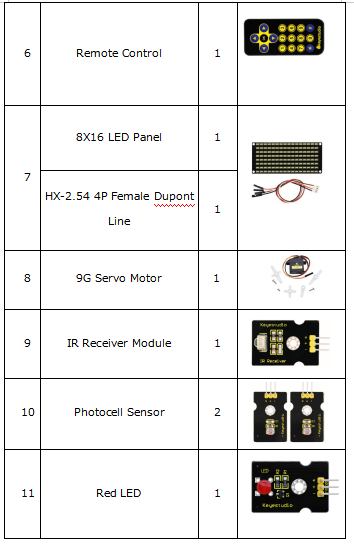

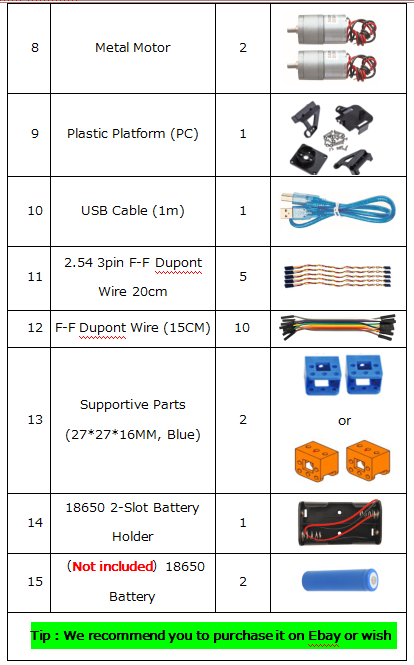

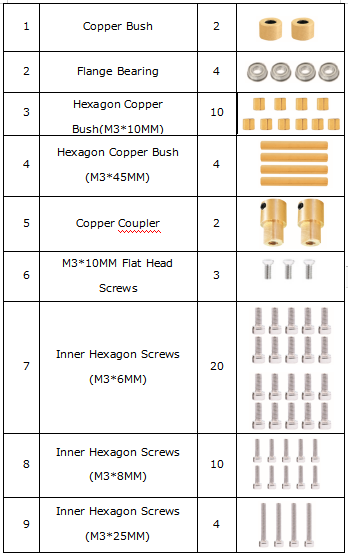

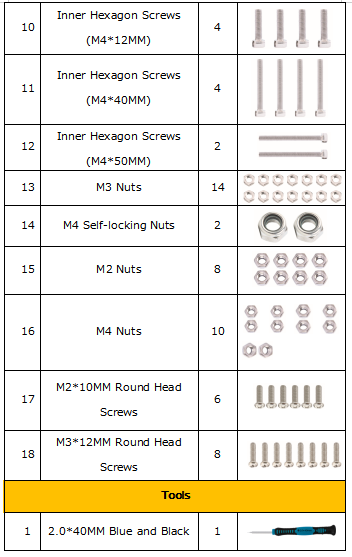

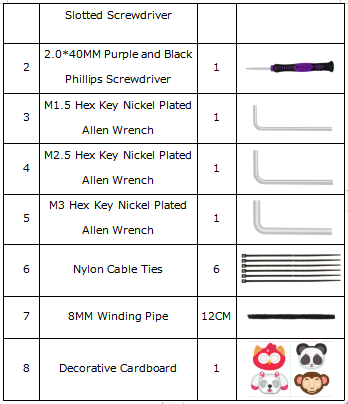

Product List

Make sure no any parts missing please when you get this robot kit. And if it is, please feel free to contact us.

Please tear off the protective film on the acrylic board before mounting the kit

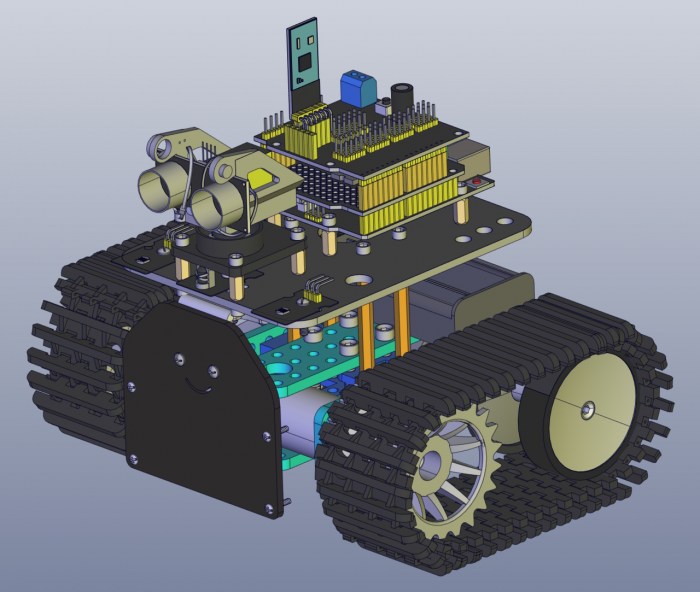

Assembly Guide

Note: Remove the Bluetooth module before uploading test code, otherwise, you will fail to upload test code

Note: Peel the plastic film off the board first when installing the smart car. To be honest, we never intend to send wood to you.

After making an inventory all the parts in this kit, then we need to mount the tank robot. Let’s install smart car in compliance with the following instructions.

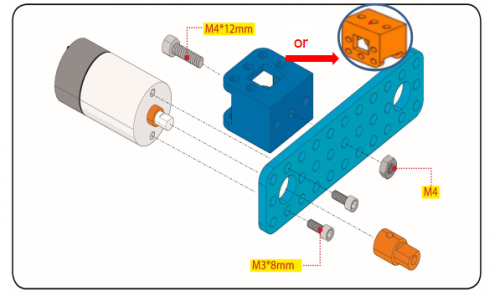

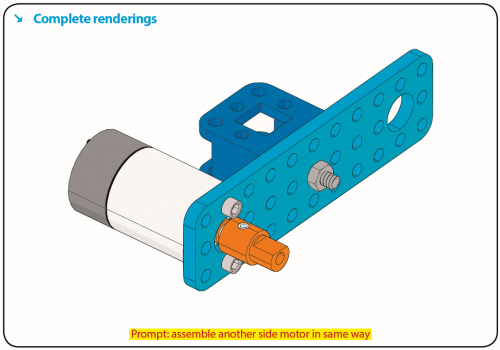

Step 1: Install Bottom Motor

Prepare the parts as follows:

- M4 Nut * 2

- Metal Motor *2

- Metal Holder *2

- Copper Coupler *2

- Blue Supportive Parts *2

- M4*12MM Inner Hex Screw * 2

- M1.5 Hex Key Nickel Plated Allen Wrench *1

- M3 Hex Key Nickel Plated Allen Wrench *1

- M2.5 Hex Key Nickel Plated Allen Wrench *1

- M3*8MM Inner Hex Screw * 4

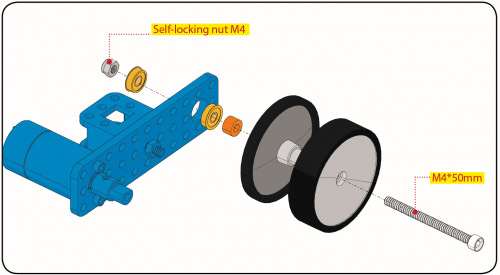

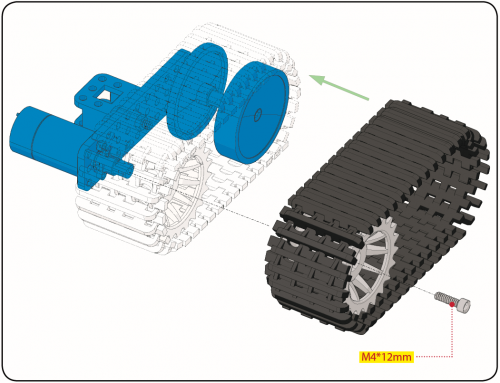

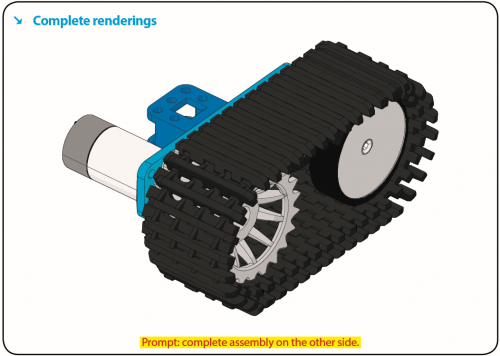

Step 2: Install Driver Wheel

Prepare the parts as follows:

- M4*12MM Inner Hex Screw * 2

- M4*50MM Inner Hex Screw * 2

- Tank Load-bearing Wheel * 2

- Flange Bearing * 4

- Copper Bush *2

- Caterpillar Band *2

- M4 Self-locking Nut * 2

- M3 Hex Key Nickel Plated Allen Wrench *1

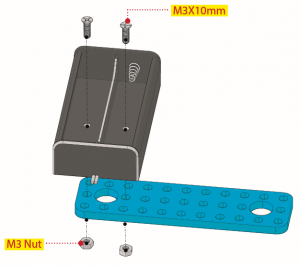

Step 3: Install the Battery Holder

Prepare the parts as follows:

- Battery Holder *1

- M3 Nut * 2

- Blue Metal holder *2

- M4 Nut *8

- M3*10MM Flat Head Screw * 2

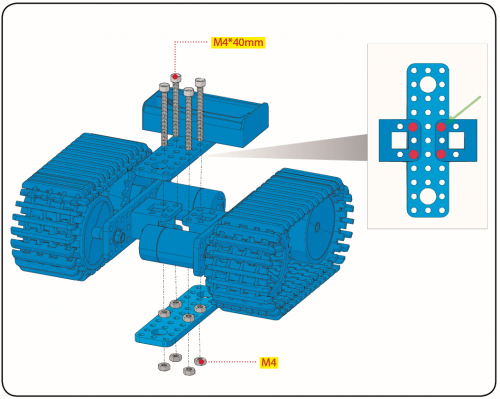

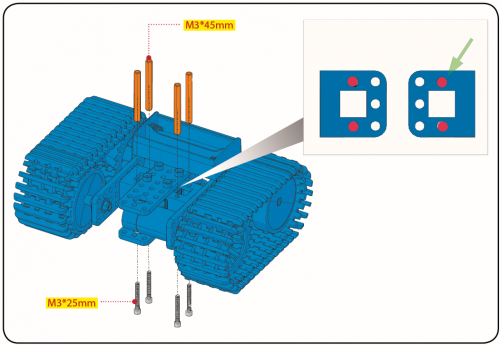

- M4*40MM Inner Hex Screw *4

- M2.5 Hex Key Nickel Plated Allen Wrench*1

- M3 Hex Key Nickel Plated Allen Wrench *1

- M3*25MM Inner Hex Screw *4

Finish the mount process. Go to fix the metal holder on the motor wheel with four M4*40MM inner hex screws and four M4 nuts.

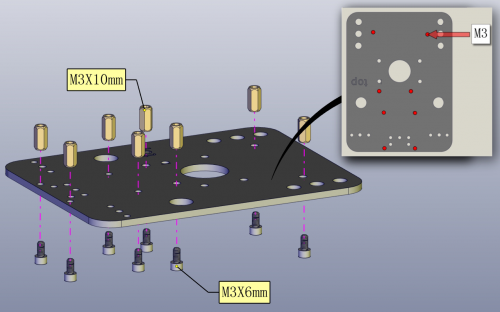

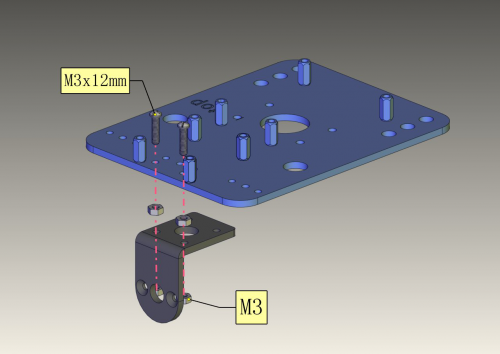

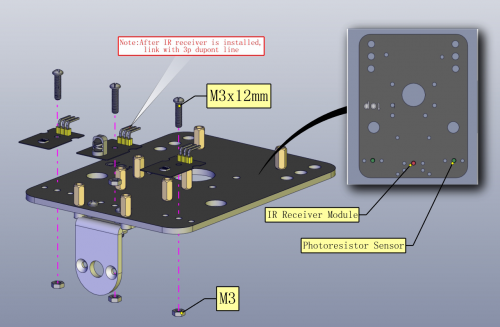

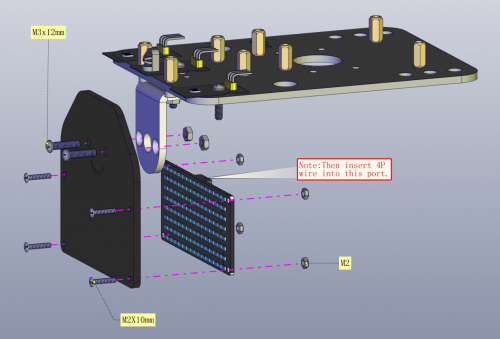

Step 4: Mount Acrylic Board and Sensors

- Acrylic Board * 2

- L- type Black Bracket *1

- Photocell Sensor *2

- IR Receiver Module *1

- 8X16 LED Panel *1

- M2 Nut *4

- M3 Nut *10

- M3*6MM Inner Hex Screw * 8

- M2.5 Hex Key Allen Wrench *1

- M3*12MM Round Head Screw *7

- M3*10MM Hexagon Copper Bush *8

- M2*10MM Round Head Screw * 4

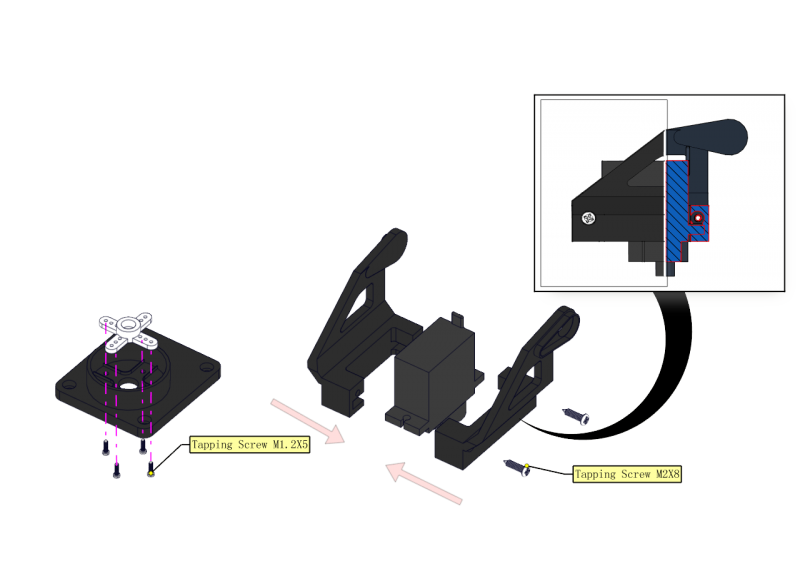

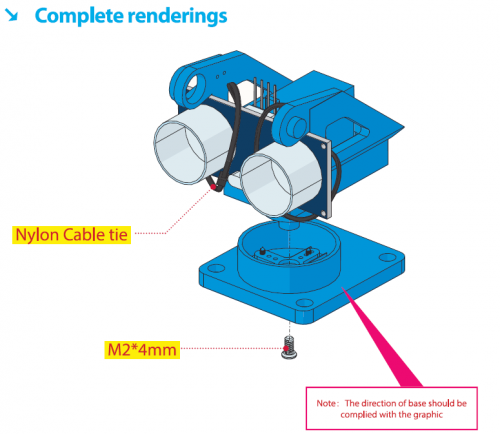

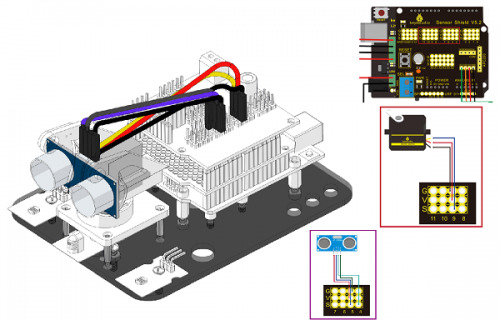

Step 5: Install the Servo Platform

Prepare the parts as follows:

- Servo *1

- Black Gimbal *1

- Cable Tie *2

- M2x8 Round Head Cross Tapping Screw *2

- Ultrasonic Sensor *1

- M2*4 Screw *1

- M1.2*5 Screw *4

Note: for convenient debugging, keep the ultrasonic module straight ahead and the angle of servo motor 90°. Therefore, we need to set servo to 90° before installing the servo platform.

You can find M1.2*5 Screws inside the bag of Plastic Platform.

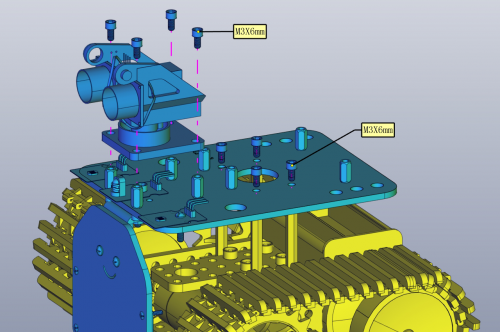

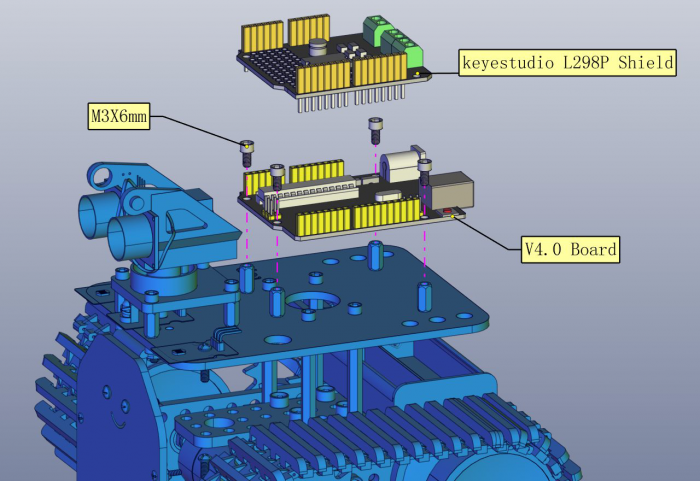

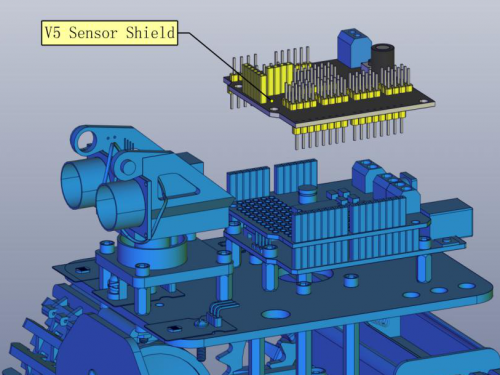

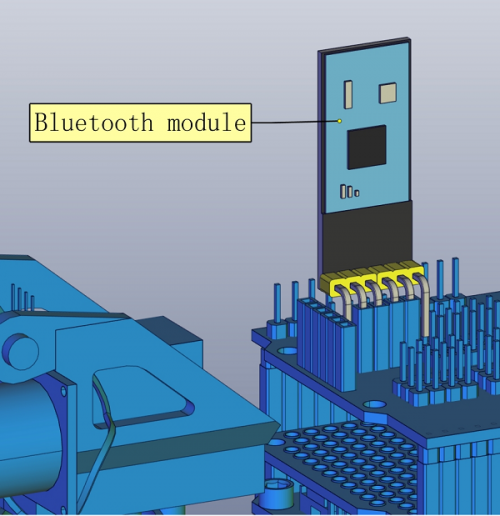

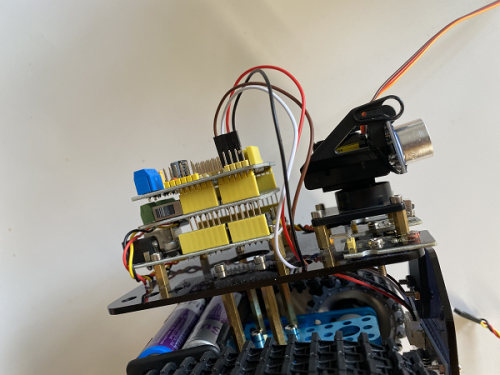

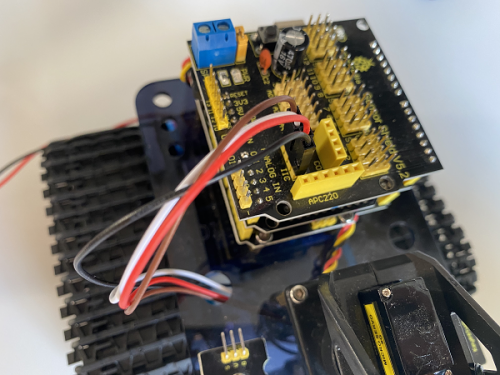

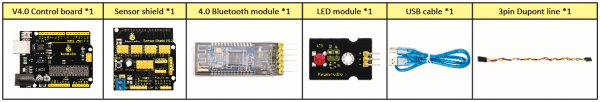

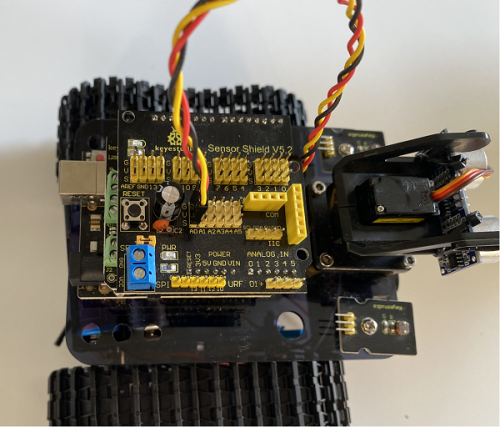

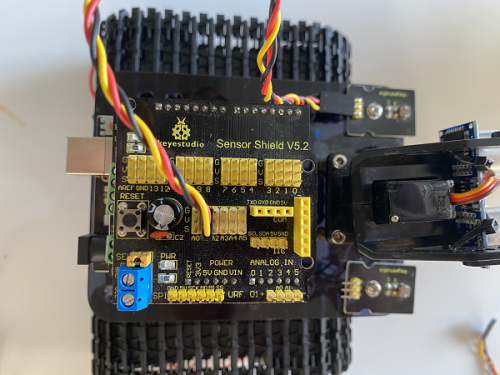

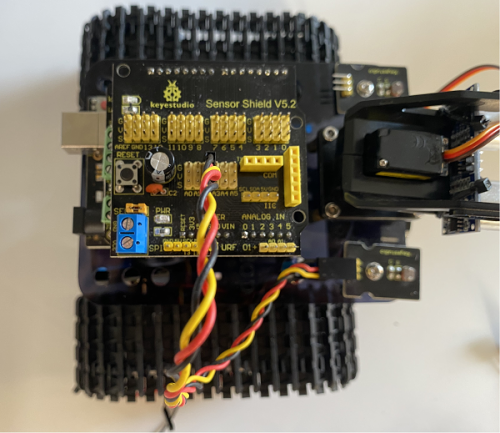

Step 6: Install Sensors and Boards

Prepare the parts as follows:

- M3*6MM Round Head Screw *12

- L298P Shield *1

- V4.0 Board *1

- V5 Sensor Shield *1

- Screwdriver *1

- Bluetooth Module *1

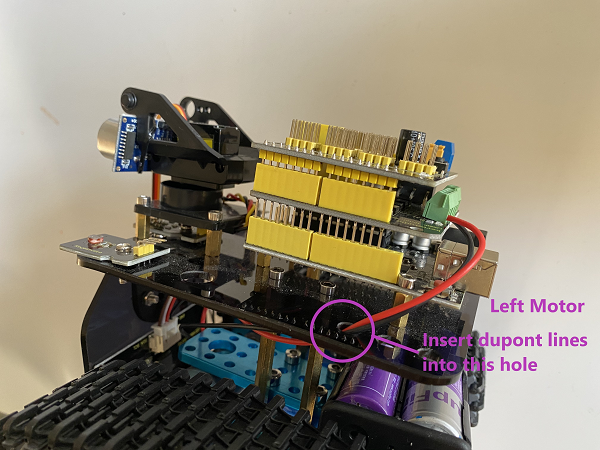

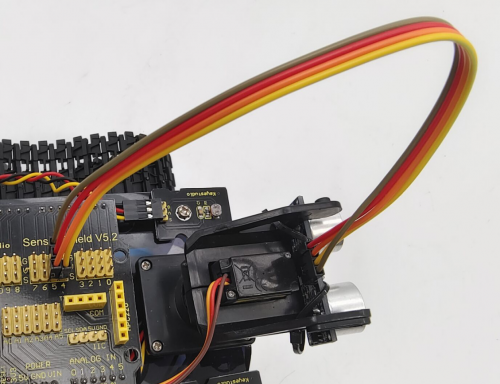

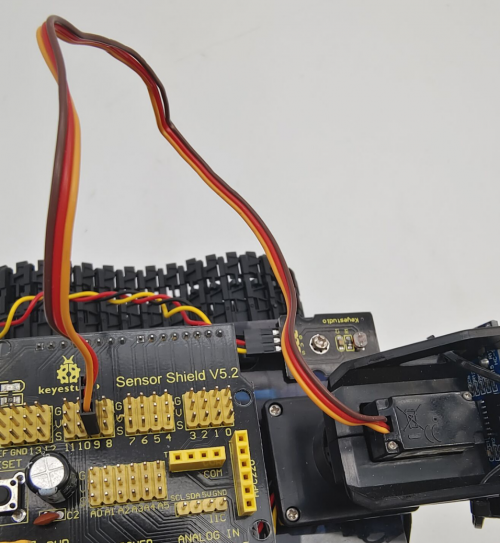

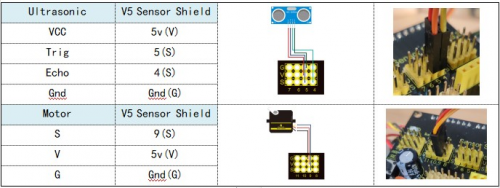

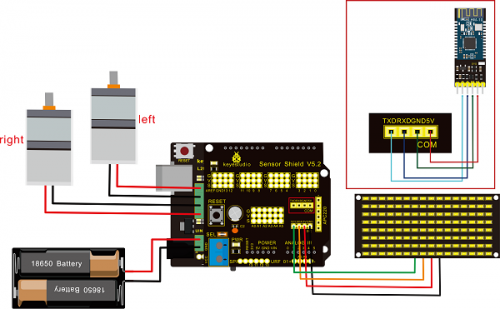

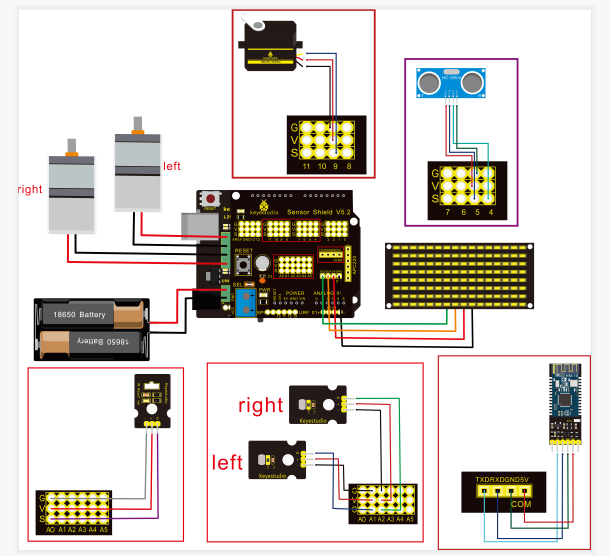

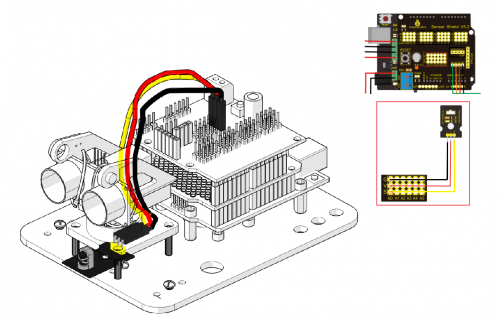

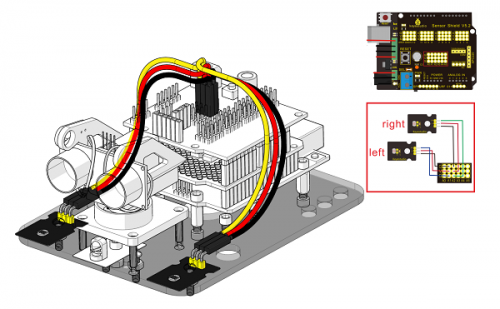

Step 7: Hook-up Guide

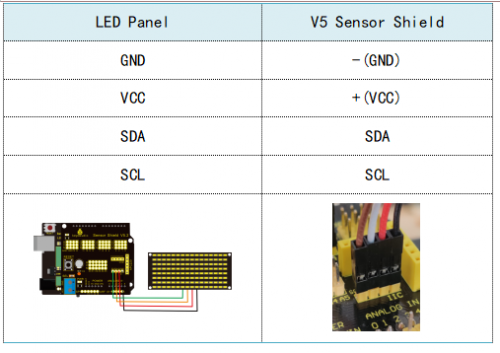

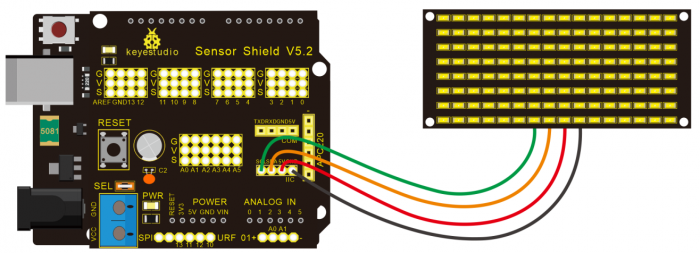

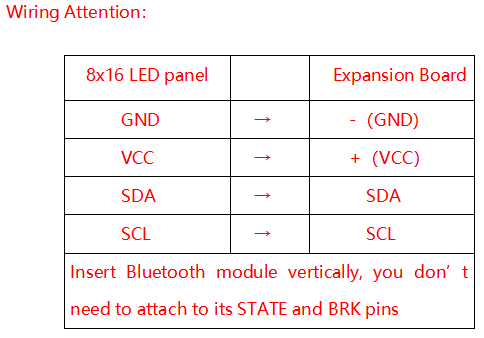

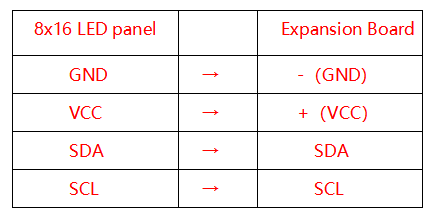

Step 8: Wire up LED Panel

Step 9: install all parts of Acrylic plate

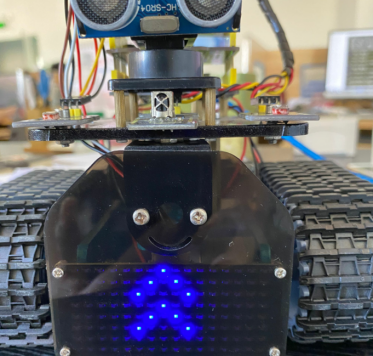

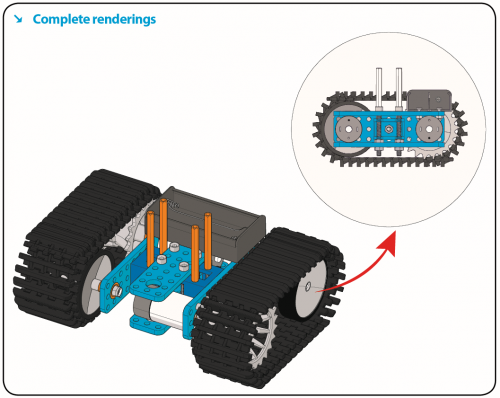

Step 10: Final Renderings

Note: Remove the Bluetooth module before uploading test code, otherwise, you will fail to upload test code.

Install Arduino IDE and Driver

Download software

When we get control board, we need to download Arduino IDE and driver firstly. You could download Arduino IDE from the official website: https://www.arduino.cc/, click the SOFTWARE on the browse bar, click “DOWNLOADS” to enter download page, as shown below:

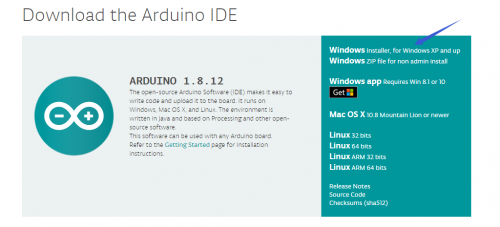

There are various versions for Arduino, just download a suitable version for your system, we will take WINDOWS system as an example to show you how to download and install.

There are two versions for WINDOWS system, one is installed version, another one is download version, you just need to download file to computer directly and unzip it. These two versions can be used normally. Choose one and download on your computer.

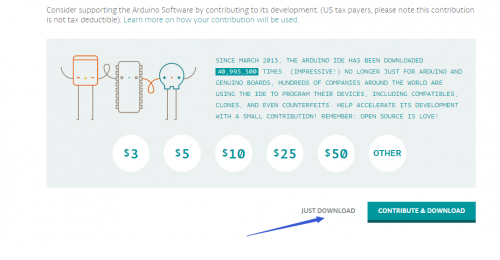

You just need to click JUST DOWNLOAD, then click the downloaded file to install it. And when the ZIP file is downloaded, you can directly unzip and start it.

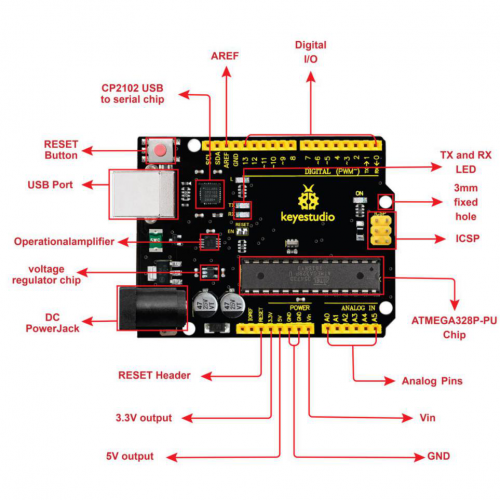

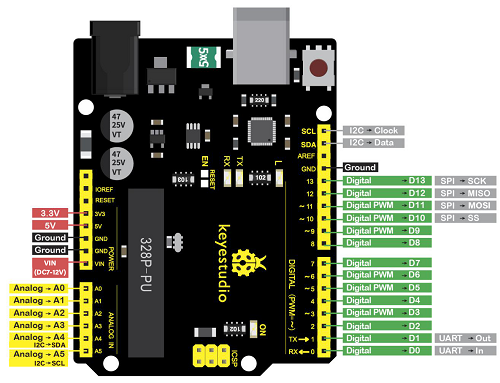

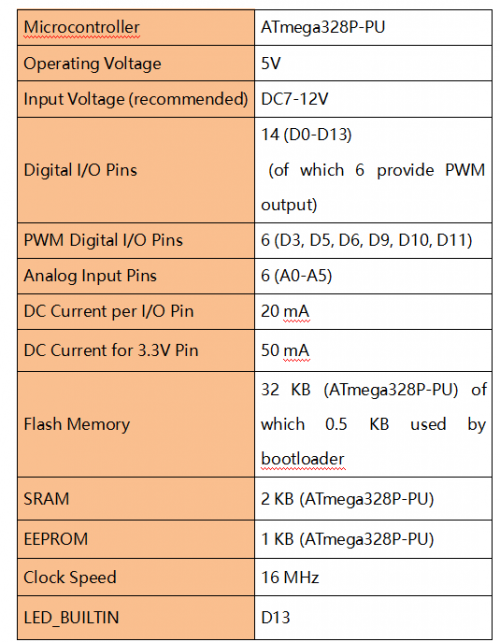

Keyestudio V4.0 Development Board

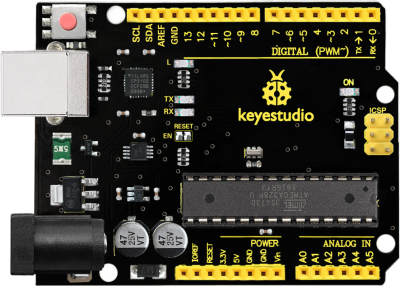

We need to know keyestudio V4.0 development board, as a core of this smart car.

keyestudio V4.0 development board is an Arduino uno-compatible board, which is based on ATmega328P MCU, and with a cp2102 Chip as a UART-to-USB converter.

It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

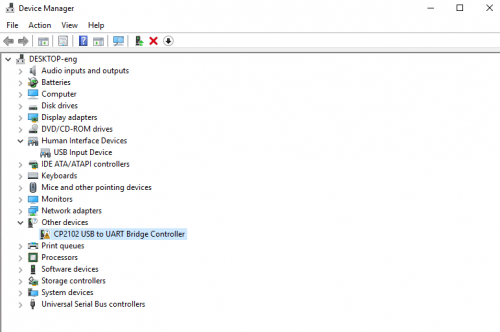

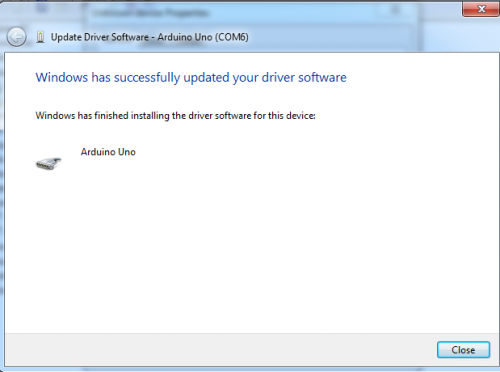

Installing driver

Let’s install the driver of keyestudio PLUS control board. The USB-TTL chip on PLUS board adopts CP2102 serial chip. The driver program of this chip is included in Arduino 1.8 version and above, which is convenient. Plug on USB port of board, the computer can recognize the hardware and automatically install the driver of CP2102.

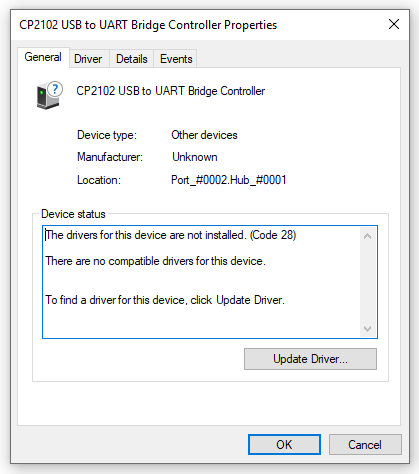

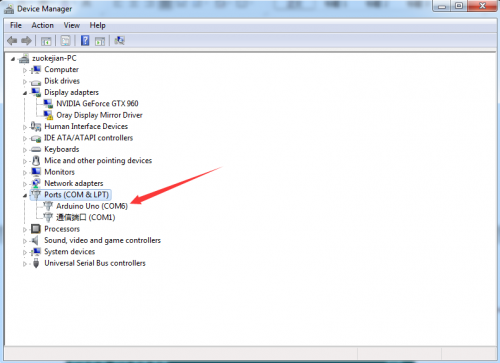

If install unsuccessfully, or you intend to install manually, open the device manager of computer. Right click Computer----- Properties----- Device Manager.

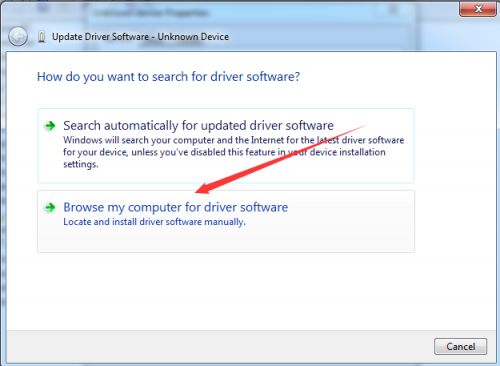

There is a yellow exclamation mark on the page, which implies installing the driver of CP2102 unsuccessfully. Then we double click the hardware and update the driver.

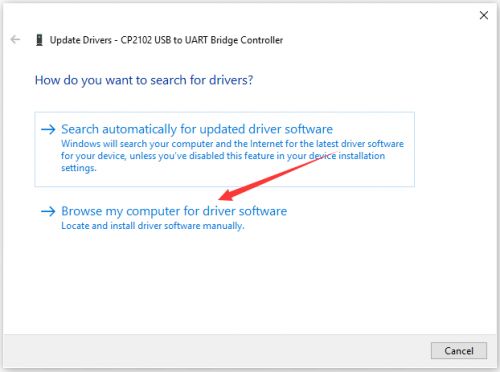

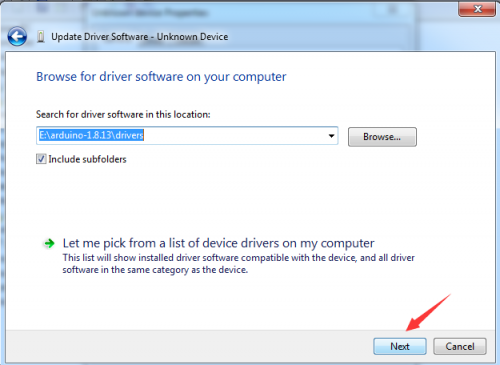

Click “OK” to enter the following page, click “browse my computer for updated driver software”, find out the installed or downloaded ARDUINO software. As shown below:

There is a DRIVERS folder in Arduino software installed package(![]() ), open driver folder and you can see the driver of CP210X series chips.

), open driver folder and you can see the driver of CP210X series chips.

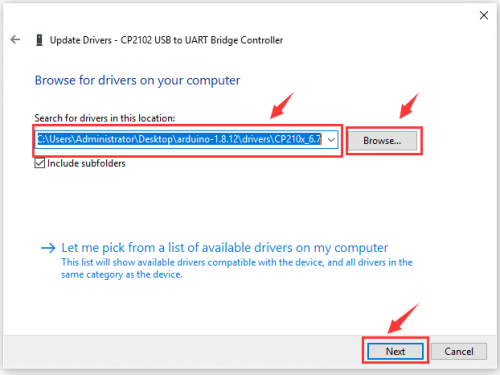

We click “Browse”, then find out the driver folder, or you could enter “driver” to search in rectangular box, then click “next”, the driver will be installed successfully. (I place Arduino software folder on the desktop, you could follow my way)

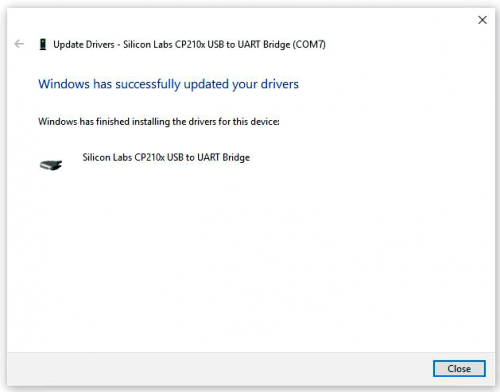

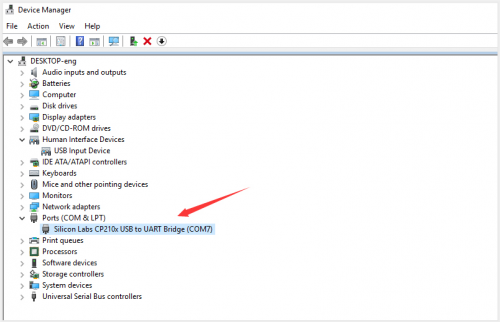

Open device manager, we will find the yellow exclamation mark disappear. The driver of CP2102 is installed successfully.

Install other visions of driver

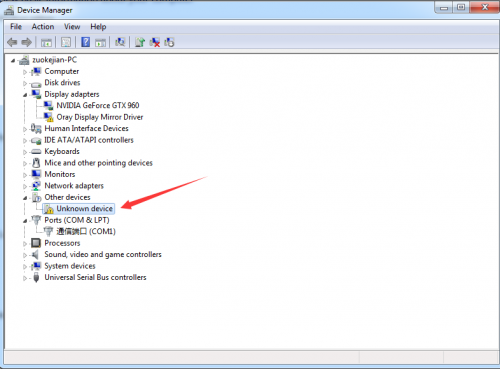

If your development board is Arduino UNO board, install the driver as follows:

Step 1: Plug in the development board, click Computer----- Properties----- Device Manager, you could see the unknown device is shown.

Step 2: Update the driver

Step 3: click“browse my computer for updated driver software”

Step 4: find out the folder where the ARDUINO software is installed, click drivers folder and tap“Next”

Step 5: the driver is installed successfully.

The device manager shows the serial port of Arduino.

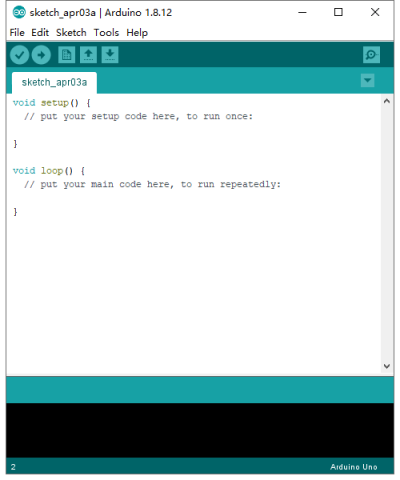

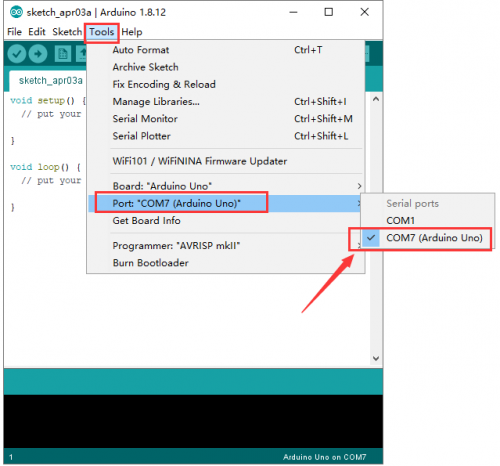

Arduino IDE Setting

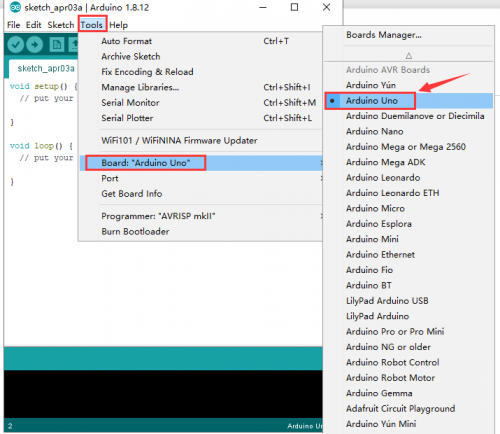

To avoid the errors when uploading the program to the board, you need to select the correct Arduino board that matches the board connected to your computer.

Then come back to the Arduino software, you should click Tools→Board, select the board. (as shown below)

Then select the correct COM port (you can see the corresponding COM port after the driver is successfully installed)

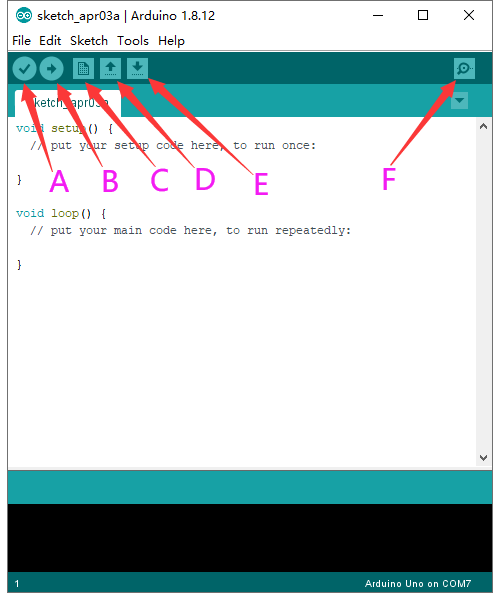

Before uploading the program to the board, let’s demonstrate the function of each symbol in the Arduino IDE toolbar.

A- Used to verify whether there is any compiling mistakes or not.

B- Used to upload the sketch to your Arduino board.

C- Used to create shortcut window of a new sketch.

D- Used to directly open an example sketch.

E- Used to save the sketch.

F- Used to send the serial data received from board to the serial monitor.

Start your first program

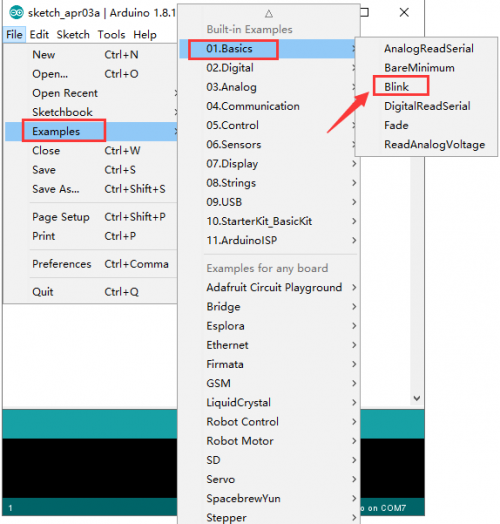

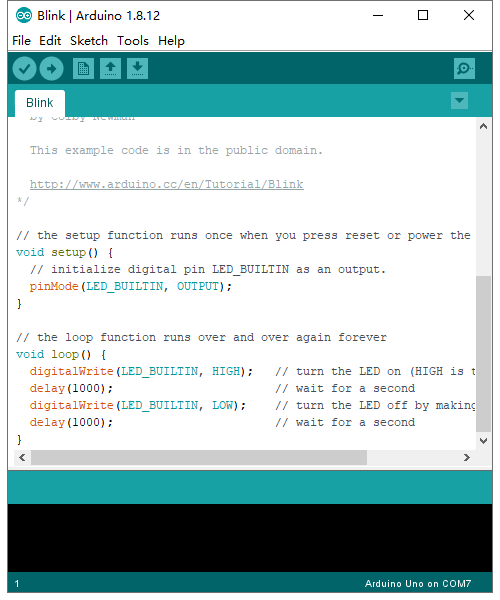

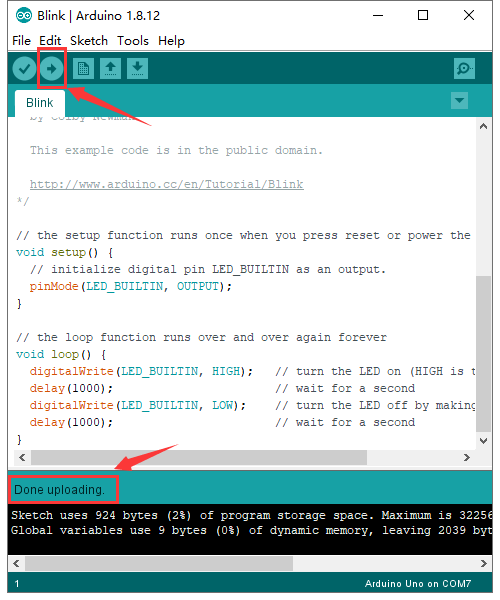

Open the file to select Example, choose BLINK from BASIC, as shown below:

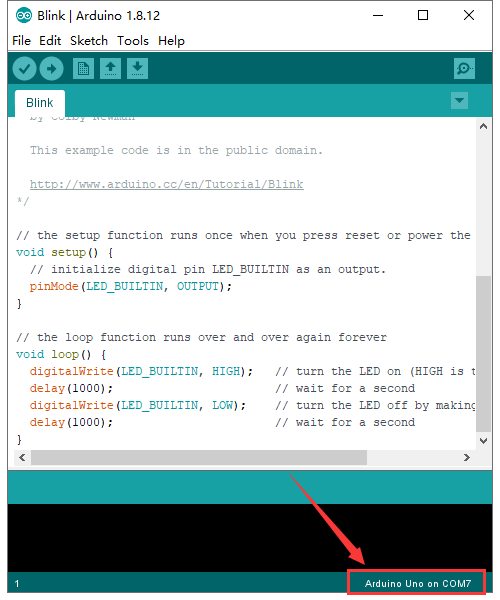

Set board and COM port, the corresponding board and COM port are shown on the lower right of IDE.

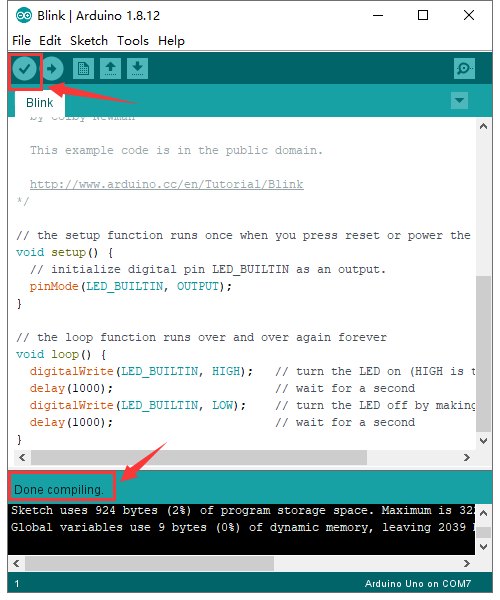

Click ![]() to start compiling the program, check errors.

to start compiling the program, check errors.

Click ![]() to upload the program, upload successfully.

to upload the program, upload successfully.

Upload the program successfully, the onboard LED lights on for 1s, lights off for 1s. Congratulation, you finish the first program.

How to Add a Library?

What are Libraries ?

Libraries are a collection of code that makes it easy for you to connect to a sensor,display, module, etc.

For example, the built-in LiquidCrystal library helps talk to LCD displays. There are hundreds of additional libraries available on the Internet for download.

The built-in libraries and some of these additional libraries are listed in the reference.

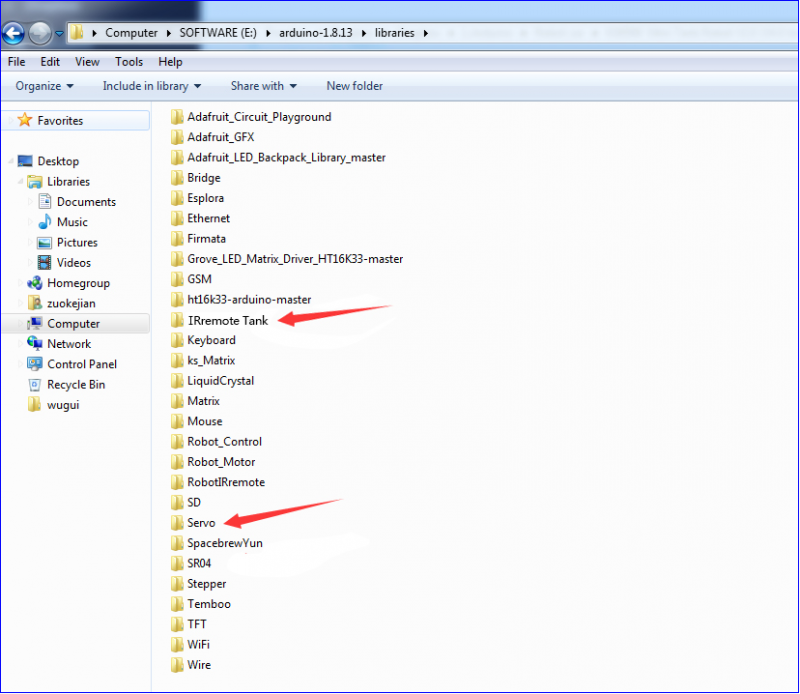

Here we will introduce the most simple way for you to add libraries .

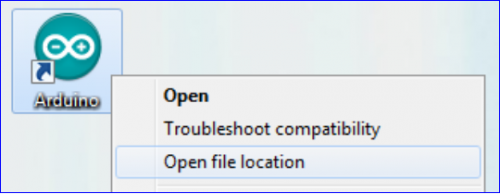

Step 1:After downloading well the Arduino IDE, you can right-click the icon of Arduino IDE.

Find the option "Open file location" shown as below:

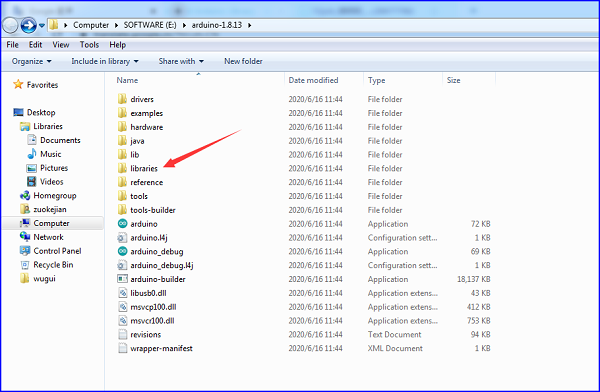

Step 2: Enter it to find out libraries folder which is the library file of Arduino.

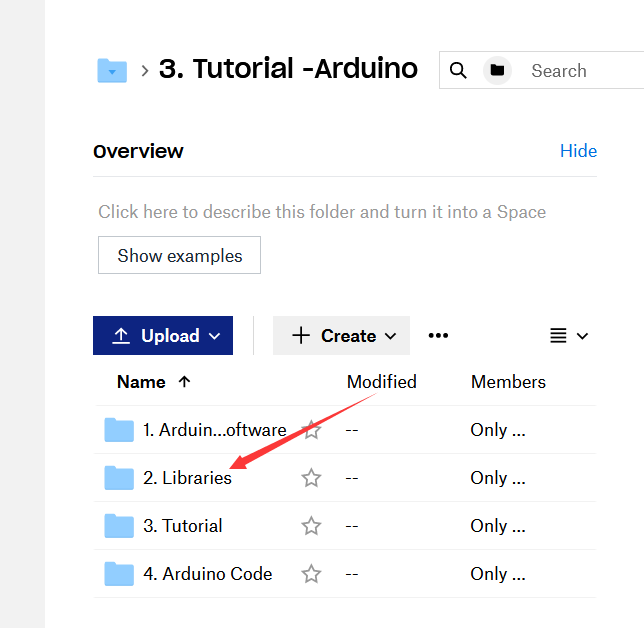

Step 3:Next to find out the“libraries”of tank robot(seen in the link: https://fs.keyestudio.com/KS0428), you just need to replicate and paste into the libraries folder of Arduino IDE.

Then the libraries of tank robot are installed successfully, as shown below:

Projects

Project 1: LED Blink

For the starter and enthusiast, this is a fundamental program---LED Blink.

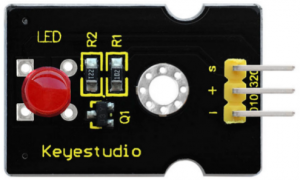

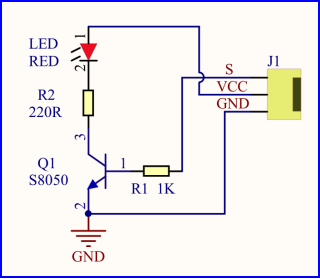

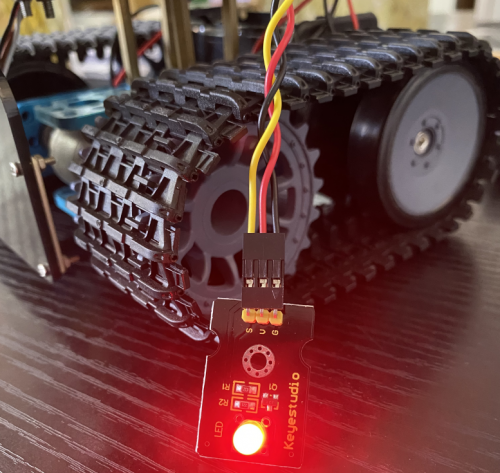

LED, the abbreviation of light emitting diodes, consist of Ga, As, P, N chemical compound and so on. The LED can flash diverse color by altering the delay time in the test code. When in control, power on GND and VCC, the LED will be on if S end is high level; nevertheless, it will go off.

(2)Specification

- Control interface: digital port

- Working voltage: DC 3.3-5V

- Pin spacing: 2.54mm

- LED display color: red

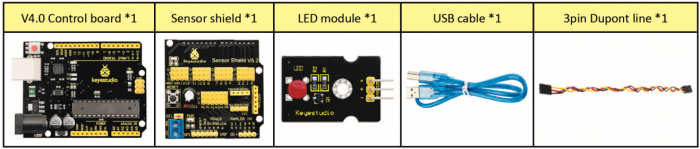

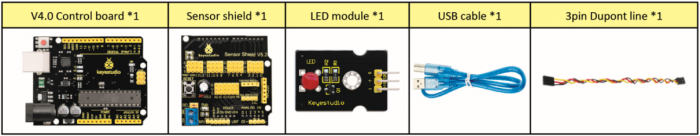

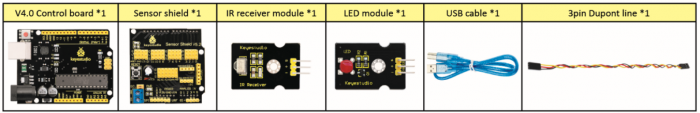

(3)Equipment

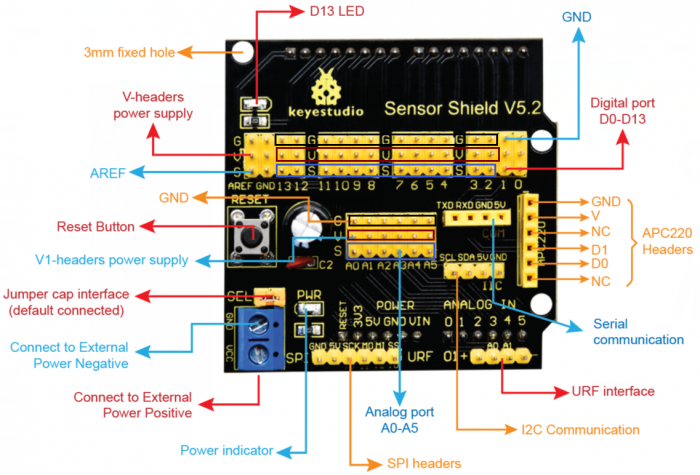

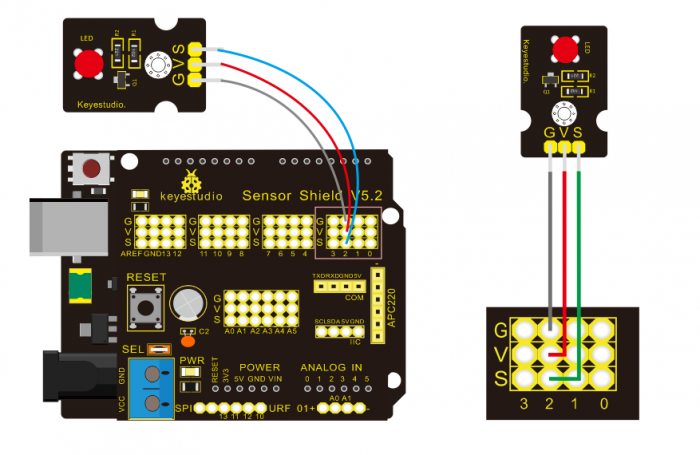

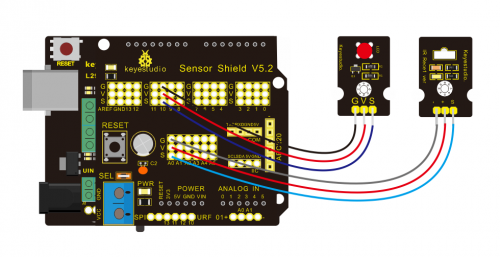

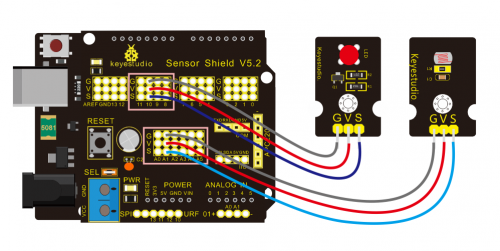

(4) V5 Sensor Shield

There will be troublesome when we combine Arduino development boards with numerous sensors. However, the V5 sensor shield, compatible with Arduino development board, address this problem perfectly. Just stack V5 board on it.

This sensor shield can be inserted into 3pin sensor modules and breaks out some some communication pins, like serial, IIC, and SPI communication as well.

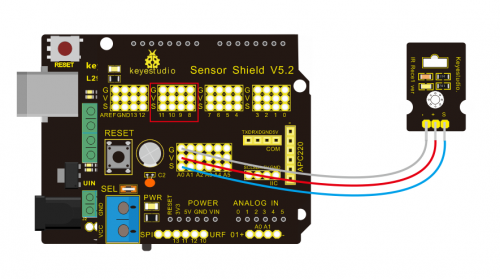

Connection Diagram:

Seen from the above diagram, LED is linked with D2

(5) Test Code

/*

keyestudio Mini Tank Robot V2

lesson 1.1

Blink

http://www.keyestudio.com

*/

void setup()

{

pinMode(2, OUTPUT);// initialize digital pin 2 as an output.

}

void loop() // the loop function runs over and over again forever

{

digitalWrite(2, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(2, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}

//****************************************************************

(6) Test Result

(There will be contradict about serial communication between code and Bluetooth when uploading code, therefore, don’t link with Bluetooth module before uploading code.) Upload the program on the development board, LED flicker with the interval of 1s.

(7)Code Explanation

pinMode(2,OUTPUT) - Set pin2 to OUTPUT

digitalWrite(2,HIGH) - When set pin2 to HIGH level(output 5V) or to LOW level(output 0V)

(8)Extension Practice We succeed to blink LED. Next, let’s observe what LED will change if we modify pins and delay time.

Connection Diagram

We’ve altered pins and connected LED to D10.

Test Code:

/*

keyestudio Mini Tank Robot V2

lesson 1.2

delay

http://www.keyestudio.com

*/

void setup() { // initialize digital pin 10 as an output.

pinMode(10, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(10, HIGH); // turn the LED on (HIGH is the voltage level)

delay(100); // wait for 0.1 second

digitalWrite(10, LOW); // turn the LED off by making the voltage LOW

delay(100); // wait for 0.1 second

}

//****************************************************************

The LED flickers faster than before through the test result, therefore, pins and delay time affect flash frequency.

Project 2: Adjust LED Brightness

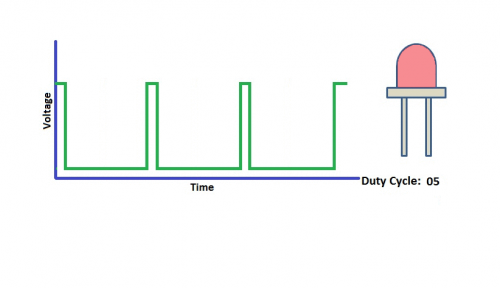

(1)Description In previous lesson, we control LED on and off and make it blink. In this project, we will control LED brightness through PWM to simulate breathing effect. Similarly, you can change the step length and delay time in the code so as to demonstrate different breathing effect. PWM is a means of controlling the analog output via digital means. Digital control is used to generate square waves with different duty cycles (a signal that constantly switches between high and low levels) to control the analog output.In general, the input voltage of port are 0V and 5V. What if the 3V is required? Or what if switch among 1V, 3V and 3.5V? We can’t change resistor constantly. For this situation, we need to control by PWM.

For the Arduino digital port voltage output, there are only LOW and HIGH, which correspond to the voltage output of 0V and 5V. You can define LOW as 0 and HIGH as 1, and let the Arduino output five hundred 0 or 1 signals within 1 second. If output five hundred 1, that is 5V; if all of which is 1, that is 0V. If output 010101010101 in this way then the output port is 2.5V, which is like showing movie. The movie we watch are not completely continuous. It actually outputs 25 pictures per second. In this case, the human can’t tell it, neither does PWM. If want different voltage, need to control the ratio of 0 and 1. The more 0,1 signals output per unit time, the more accurately control.

(2) Specification

- Control interface: digital port

- Working voltage: DC 3.3-5V

- Pin spacing: 2.54mm

- Display color: red

(5) Test Code

/*

keyestudio Mini Tank Robot V2

lesson 2.1

pwm

http://www.keyestudio.com

*/

int ledPin = 10; // Define the LED pin at D10

int value;

void setup ()

{

pinMode (ledPin, OUTPUT); // initialize ledpin as an output.

}

void loop ()

{

for (value = 0; value <255; value = value + 1)

{

analogWrite (ledPin, value); // LED lights gradually light up

delay (5); // delay 5MS

}

for (value = 255; value> 0; value = value-1)

{

analogWrite (ledPin, value); // LED gradually goes out

delay (5); // delay 5MS

}}//**********************************************************

(6)Test Result

Upload test code successfully, LED gradually becomes brighter then darker, like human breath, rather than light on and off immediately.

(7)Code Explanation

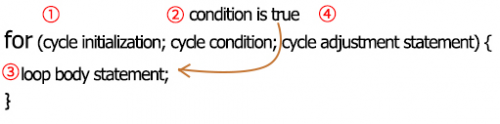

When we need to repeat some statements, we could use FOR statement.

FOR statement format is shown below:

FOR cyclic sequence: Round 1:1 → 2 → 3 → 4 Round 2:2 → 3 → 4 … Until number 2 is not established, “for”loop is over, After knowing this order, go back to code: for (int value = 0; value < 255; value=value+1){

...

} for (int value = 255; value >0; value=value-1){

...

}

The two“for”statements make value increase from 0 to 255, then reduce from 255 to 0, then increase to 255,....infinitely loop

There is a new function in the following ----- analogWrite()

We know that digital port only has two state of 0 and 1. So how to send an analog value to a digital value? Here,this function is needed. Let’s observe the Arduino board and find 6 pins marked“~”which can output PWM signals.

Function format as follows:

analogWrite(pin,value)

analogWrite() is used to write an analog value from 0~255 for PWM port, so the value is in the range of 0~255. Attention that you only write the digital pins with PWM function, such as pin 3, 5, 6, 9, 10, 11.

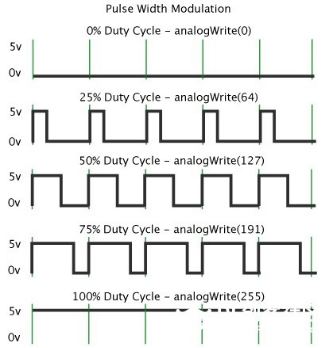

PWM is a technology to obtain analog quantity through digital method. Digital control forms a square wave, and the square wave signal only has two states of turning on and off (that is, high or low levels). By controlling the ratio of the duration of turning on and off, a voltage varying from 0 to 5V can be simulated. The time turning on(academically referred to as high level) is called pulse width, so PWM is also called pulse width modulation.

Through the following five square waves, let’s acknowledge more about PWM.

In the above figure, the green line represents a period, and value of analogWrite() corresponds to a percentage which is called Duty Cycle as well. Duty cycle implies that high-level duration is divided by low-level duration in a cycle. From top to bottom, the duty cycle of first square wave is 0% and its corresponding value is 0. The LED brightness is lowest, that is, turn off. The more time high level lasts, the brighter the LED.

Therefore, the last duty cycle is 100%, which correspond to 255, LED is brightest. 25% means darker.

PWM mostly is used for adjusting the LED brightness or rotation speed of motor.

It plays vital role in controlling smart robot car. I believe that you can’t wait to enter next project.

(8) Extension Practice:

Let’s modify the value of delay and remain the pin unchanged, then observe how LED changes.

/*

keyestudio Mini Tank Robot V2

lesson 2.2

pwm-slow

http://www.keyestudio.com

*/

int ledPin = 10; // Define the LED pin at D10

int value;

void setup ()

{

pinMode (ledPin, OUTPUT); // initialize ledpin as an output.

}

void loop ()

{

for (value = 0; value <255; value = value + 1)

{

analogWrite (ledPin, value); // LED lights gradually light up

delay (30); // delay 30MS

}

for (value = 255; value> 0; value = value-1)

{

analogWrite (ledPin, value); // LED gradually goes out

delay (30); // delay 30MS

}}//**********************************************************

Upload code on the development board and LED gradually get brighter then darker.

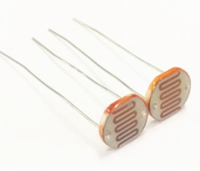

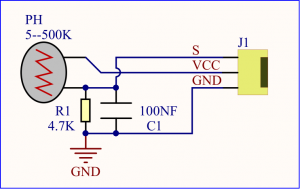

Project 3: Photoresistor Sensor

(1)Description

The photoresistor is a special resistor made of semiconductor materials such as CdS or Selenide septum. The surface is also coated with moisture-proof resin, which has a photoconductive effect. It is sensitive to ambient light. Its resistance varies from different light intensities.

We use the characteristics of the photo-resistor to design the circuit and generate the photo-resistor module.

Connecting the signal pin of photocell module to Analog port, when the stronger the light intensity, the greater the voltage of analog port, the greater the analog value is.

On the contrary, the weaker the light intensity, the smaller the voltage of analog port, the smaller the analog value is.

Based on that, we can use the photocell module to read the analog value, so get the ambient light intensity.

(2)Specification

- Resistance:5K ohm-0.5Mohm

- Interface Type: analog

- Working Voltage: 3.3V-5V

- Easy installation: with screw fixing holes

- Pin spacing: 2.54mm

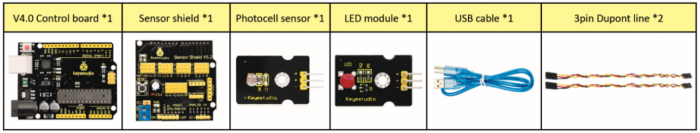

(3)Equipment

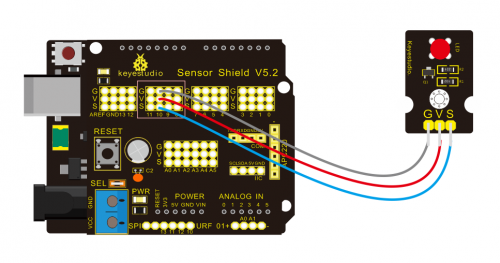

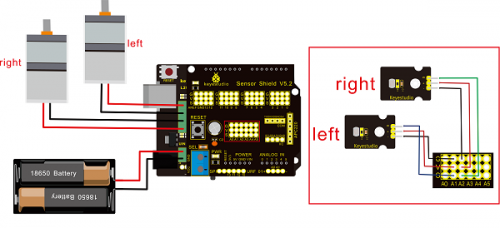

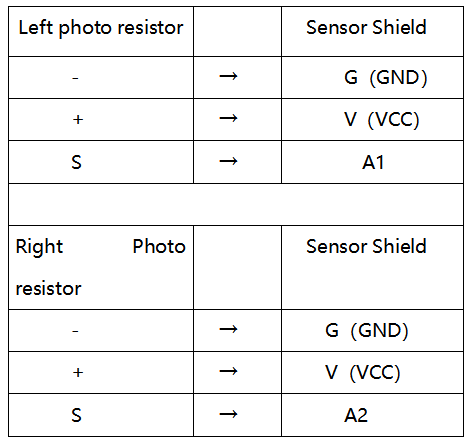

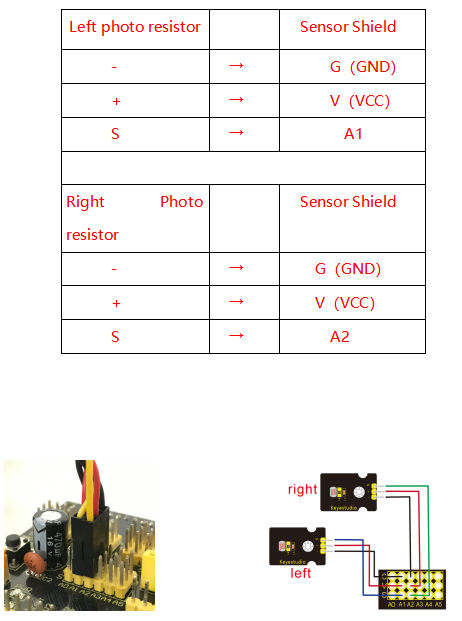

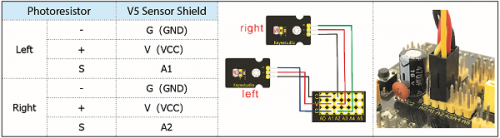

Connection Diagram:

The two photoresistor sensors are linked with A1 and A2, then finish the experiment via photoresistor connected to A1. Then finish the following experiment via photoresistor connected A1. Let’s read its analog value.

(4)Test Code

/*

keyestudio Mini Tank Robot V2

lesson 3.1

photocell

http://www.keyestudio.com

*/

int sensorPin = A1; // select the input pin for the photocell

int sensorValue = 0; // variable to store the value coming from the sensor

void setup() {

Serial.begin(9600);

}

void loop() {

sensorValue = analogRead(sensorPin); // read the value from the sensor:

Serial.println(sensorValue); //Serial port prints the resistance value

delay(500);

}

//******************************************************

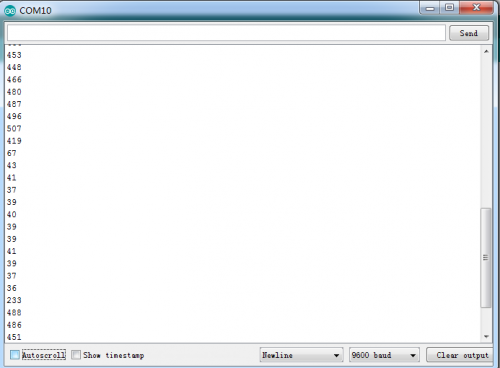

(5)Test Result

Upload code on development board, open serial monitor, check if its value diminishes when covering photoresistor. However, the value increases when uncovered.

(6)Code Explanation analogRead(sensorPin):read the analog value of photoresistor via analog ports. Serial.begin(9600): Initialize the serial port, baud rate of serial communication is 9600 Serial.println : Serial port prints and word wrap.

(7)Extension Practice

We’ve known how to read the value of photoresistor. Let’s combine photoresistor with LED and view the status of LED.

PWM restrains the brightness, so LED is linked with PWM pins, connect LED to pin 10, keep pin of photoresistor unchanged, then design the code:

/*keyestudio Mini Tank Robot V2

lesson 3.2

photocell-analog output

http://www.keyestudio.com

*/

int analogInPin = A1; // Analog input pin that the photocell is attached to

int analogOutPin = 10; // Analog output pin that the LED is attached to

int sensorValue = 0; // value read from the pot

int outputValue = 0; // value output to the PWM (analog out)

void setup() {

Serial.begin(9600);

}

void loop() {

// read the analog in value:

sensorValue = analogRead(analogInPin);

// map it to the range of the analog out:

outputValue = map(sensorValue, 0, 1023, 0, 255);

// change the analog out value:

analogWrite(analogOutPin, outputValue);

// wait 2 milliseconds before the next loop for the analog-to-digital

// converter to settle after the last reading:

Serial.println(sensorValue); //serial port prints the value of photoresistor

delay(2);

}

//***************************************************************

Upload code, press it by hand and see the the LED brightness.

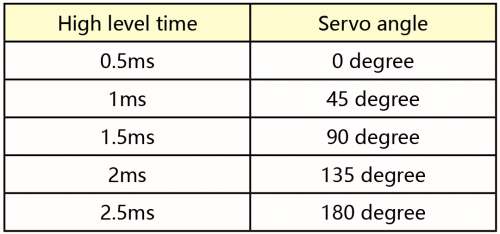

Project 4: Servo Control

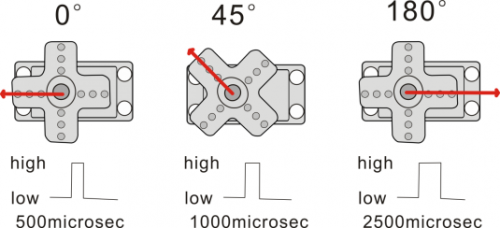

(1)Description

Servo motor is a position control rotary actuator. It mainly consists of housing, circuit board, core-less motor, gear and position sensor. Its working principle is that the servo receives the signal sent by MCU or receiver and produces a reference signal with a period of 20ms and width of 1.5ms, then compares the acquired DC bias voltage to the voltage of the potentiometer and obtain the voltage difference output.

When the motor speed is constant, the potentiometer is driven to rotate through the cascade reduction gear, which leads that the voltage difference is 0, and the motor stops rotating. Generally, the angle range of servo rotation is 0° --180 °

The rotation angle of servo motor is controlled by regulating the duty cycle of PWM (Pulse-Width Modulation) signal. The standard cycle of PWM signal is 20ms (50Hz). Theoretically, the width is distributed between 1ms-2ms, but in fact, it's between 0.5ms-2.5ms. The width corresponds the rotation angle from 0° to 180°. But note that for different brand motor, the same signal may have different rotation angle.

The corresponding servo angles are shown below:

(2)Specification

- Working voltage: DC 4.8V ~ 6V

- Operating angle range: about 180 ° (at 500 → 2500 μsec)

- Pulse width range: 500 → 2500 μsec

- No-load speed: 0.12 ± 0.01 sec / 60 (DC 4.8V) 0.1 ± 0.01 sec / 60 (DC 6V)

- No-load current: 200 ± 20mA (DC 4.8V) 220 ± 20mA (DC 6V)

- Stopping torque: 1.3 ± 0.01kg · cm (DC 4.8V) 1.5 ± 0.1kg · cm (DC 6V)

- Stop current: ≦ 850mA (DC 4.8V) ≦ 1000mA (DC 6V)

- Standby current: 3 ± 1mA (DC 4.8V) 4 ± 1mA (DC 6V)

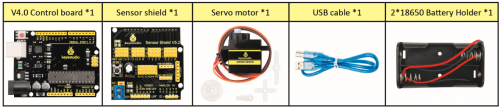

(3)Equipment

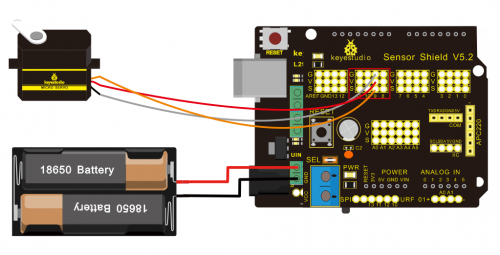

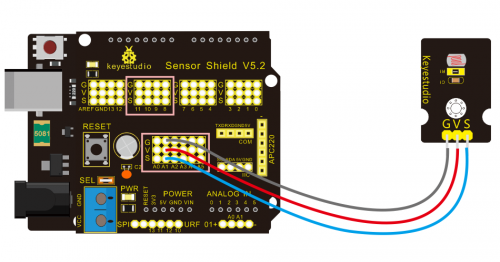

(4)Connection Diagram:

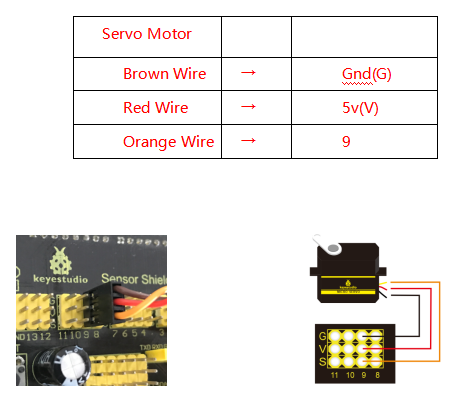

Wiring note: the brown line of servo is linked with Gnd(G), the red line is connected to 5v(V) and orange line is attached to digital 9.

The servo have to be connected to external power, due to its high demand for driving servo current. Generally, the current of development board is not enough. If without connected power, the development board could be burnt.

(5)Test Code1

/*

keyestudio Mini Tank Robot V2

lesson 4.1

Servo

http://www.keyestudio.com

*/

#define servoPin 9 //servo Pin

int pos; //angle variable of servo

int pulsewidth; // pulse width variable of servo

void setup() {

pinMode(servoPin, OUTPUT); //set servo pin to OUTPUT

procedure(0); //set the angle of servo to 0°

}

void loop() {

for (pos = 0; pos <= 180; pos += 1) { // goes from 0 degrees to 180 degrees

// in steps of 1 degree

procedure(pos); // tell servo to go to position in variable 'pos'

delay(15); //control the rotation speed of servo

}

for (pos = 180; pos >= 0; pos -= 1) { // goes from 180 degrees to 0 degrees

procedure(pos); // tell servo to go to position in variable 'pos'

delay(15);

}

}

// function to control servo

void procedure(int myangle) {

pulsewidth = myangle * 11 + 500; //calculate the value of pulse width

digitalWrite(servoPin,HIGH);

delayMicroseconds(pulsewidth); //The duration of high level is pulse width

digitalWrite(servoPin,LOW);

delay((20 - pulsewidth / 1000)); // the cycle is 20ms, the low level last for the rest of time

}

//********************************************************************

Upload code successfully, servo swings back in the range of 0° to 180°

There is another guide for restraining servo---- servo library file, the following link of official website is for your reference. https://www.arduino.cc/en/Reference/Servo

Servo library file

(6)Test Code2

/*

keyestudio Mini Tank Robot V2

lesson 4.2

servo

http://www.keyestudio.com

*/

#include <Servo.h>

Servo myservo; // create servo object to control a servo

// twelve servo objects can be created on most boards

int pos = 0; // variable to store the servo position

void setup() {

myservo.attach(9); // attaches the servo on pin 9 to the servo object

}

void loop() {

for (pos = 0; pos <= 180; pos += 1) { // goes from 0 degrees to 180 degrees

// in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(15); // waits 15ms for the servo to reach the position

}

for (pos = 180; pos >= 0; pos -= 1) { // goes from 180 degrees to 0 degrees

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(15); // waits 15ms for the servo to reach the position

}

}

//****************************************************************

(7)Test Result

Upload code successfully and power on, servo rotates in the range of 0° to 180°. The result is same. We usually control it by library file.

(8)Code Explanation

Arduino comes with #include <Servo.h> (servo function and statement) The following are some common statements of the servo function: 1. attach(interface)——Set servo interface, port 9 and 10 are available

3.write(angle)——The statement to set rotation angle of servo, the angle range is from 0° to 180° 3. read()——The statement to read angle of servo, read the command value of “write()” 4. Note: The above written format is “servo variable name, specific statement()”, for instance: myservo.attach(9)

Project 5: Ultrasonic Sensor

(1)Description

The HC-SR04 ultrasonic sensor uses sonar to determine distance to an object like bats do. It offers excellent non-contact range detection with high accuracy and stable readings in an easy-to-use package. It comes complete with ultrasonic transmitter and receiver modules.

The HC-SR04 or the ultrasonic sensor is being used in a wide range of electronics projects for creating obstacle detection and distance measuring application as well as various other applications. Here we have brought the simple method to measure the distance with arduino and ultrasonic sensor and how to use ultrasonic sensor with arduino.

(2)Specification

- Power Supply :+5V DC

- Quiescent Current : <2mA

- Working Current: 15mA

- Effectual Angle: <15°

- Ranging Distance : 2cm – 400 cm

- Resolution : 0.3 cm

- Measuring Angle: 30 degree

- Trigger Input Pulse width: 10uS

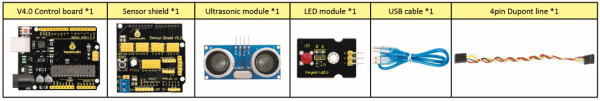

(3)Equipment

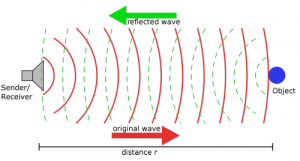

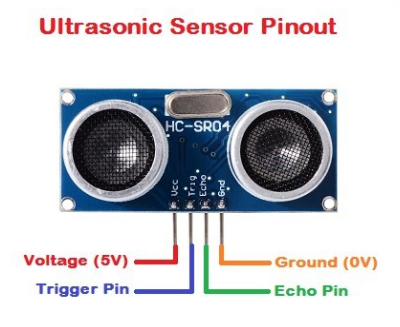

(4)The principle of ultrasonic sensor

As the above picture shown, it is like two eyes. One is transmitting end, the other is receiving end.

The ultrasonic module will emit the ultrasonic waves after trigger signal. When the ultrasonic waves encounter the object and are reflected back, the module outputs an echo signal, so it can determine the distance of object from the time difference between trigger signal and echo signal. The t is the time that emitting signal meets obstacle and returns. and the propagation speed of sound in the air is about 343m/s, therefore, distance = speed * time, because the ultrasonic wave emits and comes back, which is 2 times of distance, so it needs to be divided by 2, the distance measured by ultrasonic wave = (speed * time)/2

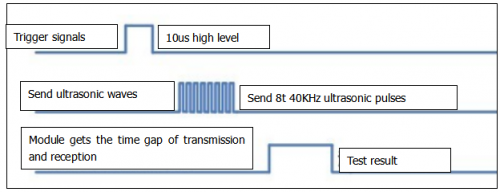

1.Use method and timing chart of ultrasonic module: Setting the delay time of Trig pin of SR04 to 10μs at least, which can trigger it to detect distance. 2. After triggering, the module will automatically send eight 40KHz ultrasonic pulses and detect whether there is a signal return. This step will be completed automatically by the module. 3. If the signal returns, the Echo pin will output a high level, and the duration of the high level is the time from the transmission of the ultrasonic wave to the return.

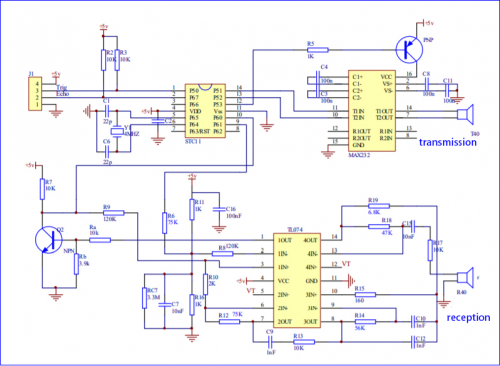

Circuit diagram of ultrasonic sensor:

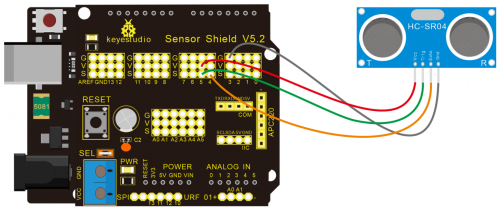

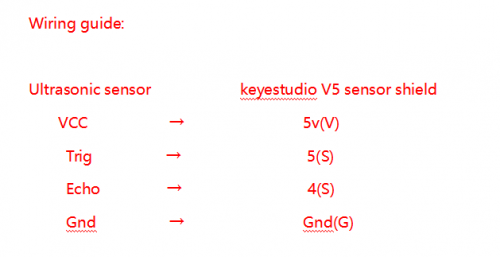

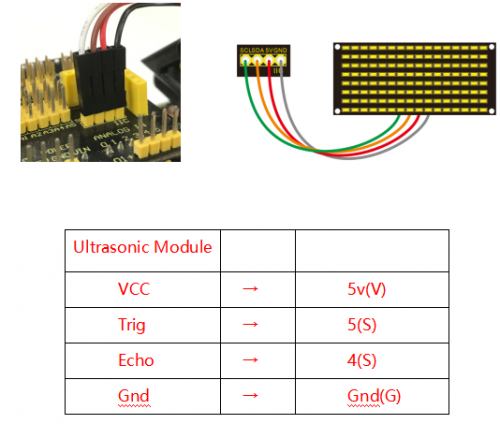

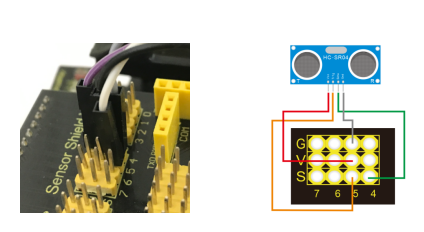

(5)Connection Diagram

(6)Test Code

/*

keyestudio Mini Tank Robot V2

lesson 5

Ultrasonic sensor

http://www.keyestudio.com

*/

int trigPin = 5; // Trigger

int echoPin = 4; // Echo

long duration, cm, inches;

void setup() {

//Serial Port begin

Serial.begin (9600);

//Define inputs and outputs

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

}

void loop() {

// The sensor is triggered by a HIGH pulse of 10 or more microseconds.

// Give a short LOW pulse beforehand to ensure a clean HIGH pulse:

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Read the signal from the sensor: a HIGH pulse whose

// duration is the time (in microseconds) from the sending

// of the ping to the reception of its echo off of an object.

duration = pulseIn(echoPin, HIGH);

// Convert the time into a distance

cm = (duration/2) / 29.1; // Divide by 29.1 or multiply by 0.0343

inches = (duration/2) / 74; // Divide by 74 or multiply by 0.0135

Serial.print(inches);

Serial.print("in, ");

Serial.print(cm);

Serial.print("cm");

Serial.println();

delay(250);

}

//****************************************************************

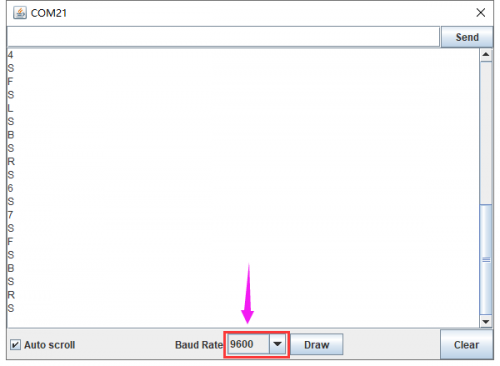

(7)Test Result Upload test code on the development board, open serial monitor and set baud rate to 9600. The detected distance will be displayed, unit is cm and inch. Hinder the ultrasonic sensor by hand, the displayed distance value is smaller.

(8)Code Explanation

int trigPin = 5; this pin is defined pin to transmit ultrasonic waves, generally output.

int echoPin = 4; this is defined as the pin of reception, generally input

cm = (duration/2) / 29.1; inches = (duration/2) / 74; by 0.0135

We can calculate the distance by using the following formula:

distance = (traveltime/2) x speed of sound

The speed of sound is: 343m/s = 0.0343 cm/uS = 1/29.1 cm/uS

Or in inches: 13503.9in/s = 0.0135in/uS = 1/74in/uS

We need to divide the traveltime by 2 because we have to take into account that the wave was sent, hit the object, and then returned back to the sensor.

(9)Extension Practice:

We have just measured the distance displayed by the ultrasonic. How about controlling the LED with the measured distance? Let's try it, connect an LED light module to the D10 pin.

/*

keyestudio Mini Tank Robot V2

lesson 5

Ultrasonic LED

http://www.keyestudio.com

*/

int trigPin = 5; // Trigger

int echoPin = 4; // Echo

long duration, cm, inches;

void setup() {

//Serial Port begin

Serial.begin (9600);

//Define inputs and outputs

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

}

void loop()

{

// The sensor is triggered by a HIGH pulse of 10 or more microseconds.

// Give a short LOW pulse beforehand to ensure a clean HIGH pulse:

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

// Read the signal from the sensor: a HIGH pulse whose

// duration is the time (in microseconds) from the sending

// of the ping to the reception of its echo off of an object.

duration = pulseIn(echoPin, HIGH);

// Convert the time into a distance

cm = (duration/2) / 29.1; // Divide by 29.1 or multiply by 0.0343

inches = (duration/2) / 74; // Divide by 74 or multiply by 0.0135

Serial.print(inches);

Serial.print("in, ");

Serial.print(cm);

Serial.print("cm");

Serial.println();

delay(250);

if (cm>=2 && cm<=10)

digitalWrite(10, HIGH);

delay(1000);

digitalWrite(10, LOW);

delay(1000);

}

//****************************************************************

Upload test code to development board and block ultrasonic sensor by hand, then check if LED is on

Project 6: IR Reception

(1)Description

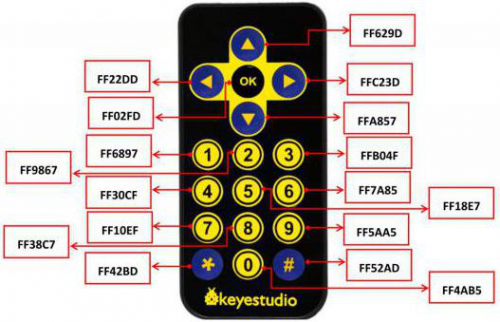

There is no doubt that infrared remote control is ubiquitous in daily life. It is used to control various household appliances, such as TVs, stereos, video recorders and satellite signal receivers. Infrared remote control is composed of infrared transmitting and infrared receiving systems, that is, an infrared remote control and infrared receiving module and a single-chip microcomputer capable of decoding.

The 38K infrared carrier signal emitted by remote controller is encoded by the encoding chip in the remote controller. It is composed of a section of pilot code, user code, user inverse code, data code, and data inverse code. The time interval of the pulse is used to distinguish whether it is a 0 or 1 signal and the encoding is made up of these 0, 1 signals.

The user code of the same remote control is unchanged. The data code can distinguish the key.

When the remote control button is pressed, the remote control sends out an infrared carrier signal. When the IR receiver receives the signal, the program will decode the carrier signal and determines which key is pressed. The MCU decodes the received 01 signal, thereby judging what key is pressed by the remote control.

Infrared receiver we use is an infrared receiver module. Mainly composed of an infrared receiver head, it is a device that integrates reception, amplification, and demodulation. Its internal IC has completed demodulation, and can achieve from infrared reception to output and be compatible with TTL signals. Additionally, it is suitable for infrared remote control and infrared data transmission. The infrared receiving module made by the receiver has only three pins, signal line, VCC and GND. It is very convenient to communicate with arduino and other microcontrollers.

(2)Specification

- Operating Voltage: 3.3-5V(DC)

- Interface: 3PIN

- Output Signal: Digital signal

- Receiving Angle: 90 degrees

- Frequency: 38khz

- Receiving Distance: 10m

(3)Equipment

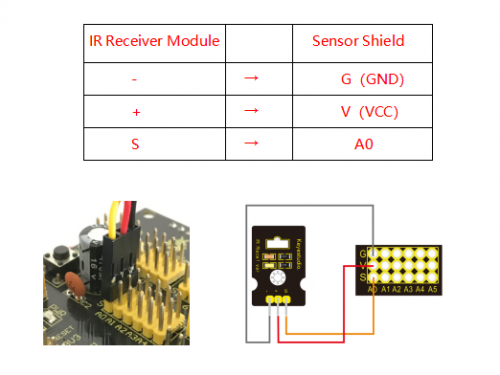

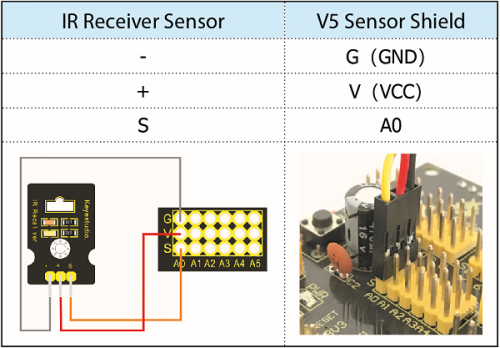

(4)Connection Diagram

Respectively link “-”、“+” and S of IR receiver module with G(GND), V(VCC)and A0 of keyestudio development board.

Attention: On the condition that digital ports are not available, analog ports can be regarded as digital ports. A0 equals to D14, A1 is equivalent to digital 15.

(5)Test Code

Firstly import library file of IR receiver module(refer to how to import Arduino library file) before designing code.

/*

keyestudio Mini Tank Robot V2

lesson 6

IRremote

http://www.keyestudio.com

*/

#include <IRremoteTank.h> // IRremote library statement

int RECV_PIN = A0; //define the pins of IR receiver as A0

IRrecv irrecv(RECV_PIN);

decode_results results; // decode results exist in the “result” of “decode results”

void setup()

{

Serial.begin(9600);

irrecv.enableIRIn(); //Enable receiver

}

void loop() {

if (irrecv.decode(&results))//decode successfully, receive a set of infrared signals

{

Serial.println(results.value, HEX);//Wrap word in 16 HEX to output and receive code

irrecv.resume(); // Receive the next value

}

delay(100);

}

//*******************************************************

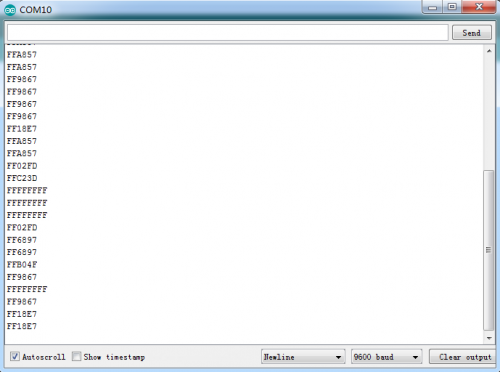

(6)Test Result

Upload test code, open serial monitor and set baud rate to 9600, point remote control to IR receiver and the corresponding value will be shown, if pressing so long, the error codes will appear.

Below we have listed out each button value of keyestudio remote control. So you can keep it for reference.

(7)Code Explanation

irrecv.enableIRIn(): after enabling IR decoding, the IR signals will be received, then function“decode()”will check continuously if decode successfully.

irrecv.decode(&results): after decoding successfully, this function will come back to “true”, and keep result in “results”. After decoding a IR signals, run the resume()function and receive the next signal (8)Extension Practice We decoded the key value of IR remote control. How about restrain LED by the measured value? We could operate an experiment to affirm. Attach a LED to D10. When keep the pin of IR receiver unchanged, LED will be on when pressing the key of remote control; press again, LED will be off.

/* keyestudio Mini Tank Robot V2

lesson 6.2

IRremote

http://www.keyestudio.com

*/

#include <IRremoteTank.h>

int RECV_PIN = A0;//define the pin of IR receiver as A0

int LED_PIN=10;//define the pin of LED

int a=0;

IRrecv irrecv(RECV_PIN);

decode_results results;

void setup()

{

Serial.begin(9600);

irrecv.enableIRIn(); // Initialize the IR receiver

pinMode(LED_PIN,OUTPUT);//set LED_pin to OUTPUT

}

void loop() {

if (irrecv.decode(&results)) {

if(results.value==0xFF02FD &a==0) // according to the above key value, press“OK”on remote control , LED will be controlled

{

digitalWrite(LED_PIN,HIGH);//LED will be on

a=1;

}

else if(results.value==0xFF02FD &a==1) //press again

{

digitalWrite(LED_PIN,LOW);//LED will go off

a=0;

}

irrecv.resume(); //receive the next value

}

}

//*******************************************************

Upload code to development board, press“OK”key on remote control to make LED on and off.

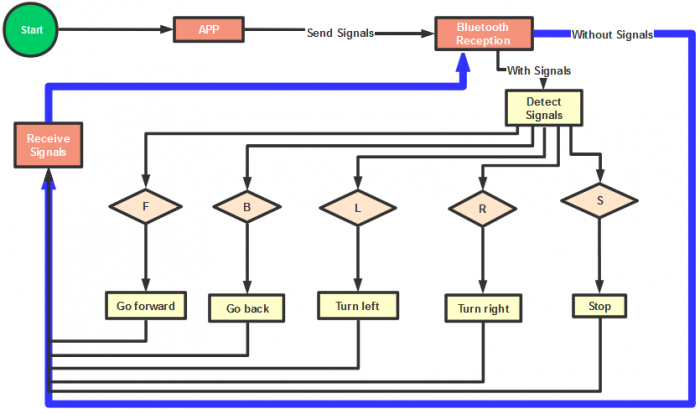

Project 7: Bluetooth Remote Control

(1)Description

Bluetooth, a simple wireless communication module most popular since the last few decades and easy to use are being used in most of the battery-powered devices.

Over the years, there have been many upgrades of Bluetooth standard to keep fulfil the demand of customers and technology according to the need of time and situation.

Over the few years, there are many things changed including data transmission rate, power consumption with wearable and IoT Devices and Security System.

Here we are going to learn about HM-10 BLE 4.0 with Arduino Board. The HM-10 is a readily available Bluetooth 4.0 module. This module is used for establishing wireless data communication. The module is designed by using the Texas Instruments CC2540 or CC2541 Bluetooth low energy (BLE) System on Chip (SoC).

(2)Specification

- Bluetooth protocol: Bluetooth Specification V4.0 BLE

- No byte limit in serial port Transceiving

- In open environment, realize 100m ultra-distance communication with iphone4s

- Working frequency: 2.4GHz ISM band

- Modulation method: GFSK(Gaussian Frequency Shift Keying)

- Transmission power: -23dbm, -6dbm, 0dbm, 6dbm, can be modified by AT command.

- Sensitivity: ≤-84dBm at 0.1% BER

- Transmission rate: Asynchronous: 6K bytes ; Synchronous: 6k Bytes

- Security feature: Authentication and encryption

- Supporting service: Central & Peripheral UUID FFE0, FFE1

- Power consumption: Auto sleep mode, stand by current 400uA~800uA, 8.5mA during transmission.

- Power supply: 5V DC

- Working temperature: –5 to +65 Centigrade

(3)Equipment

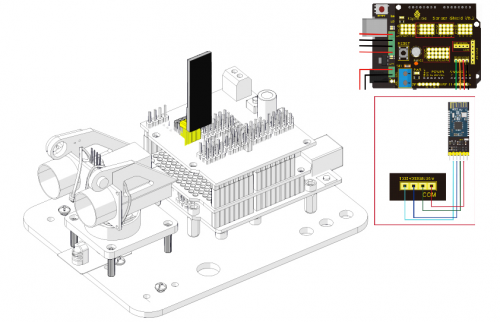

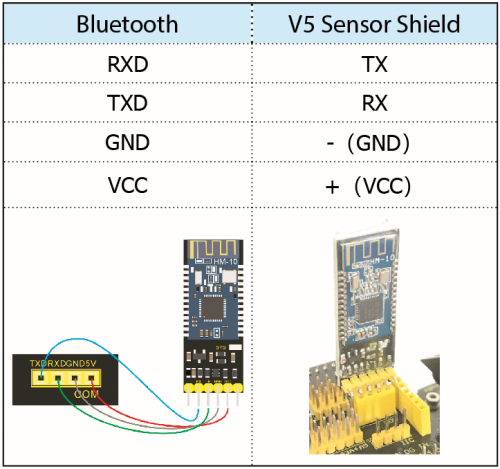

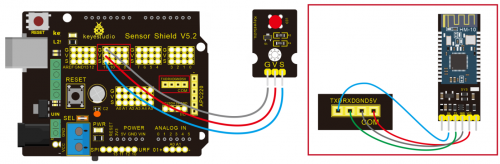

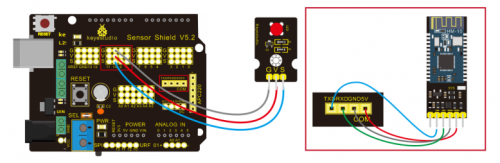

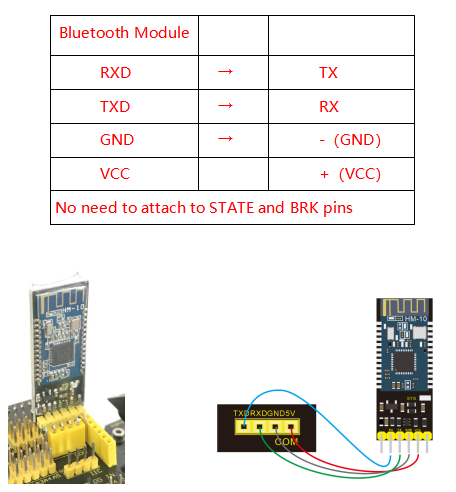

(4)Connection Diagram

- 1. STATE: state test pins, connected to internal LED, generally keep it unconnected.

- 2. RXD: serial interface, receiving terminal.

- 3. TXD: serial interface, transmitting terminal.

- 4. GND: Ground.

- 5. VCC: positive pole of the power source.

- 6. EN/BRK: break connect, it means breaking the Bluetooth connection, generally, keep it unconnected.

(5)Test Code

/*

keyestudio Mini Tank Robot v2.0

lesson 7.1

bluetooth

http://www.keyestudio.com

*/

char ble_val; //character variable: save the value of Bluetooth reception

void setup() {

Serial.begin(9600);

}

void loop() {

if(Serial.available() > 0) //Judge if there is data in serial buffer

{

ble_val = Serial.read(); //Read data from serial buffer

Serial.println(ble_val); //Print

}}

//*******************************************

(There will be contradiction between serial communication of code and communication of Bluetooth when uploading code, therefore, don’t link with Bluetooth module before uploading code.)

After uploading code on development board, then insert Bluetooth module, wait for the command from cellphone.

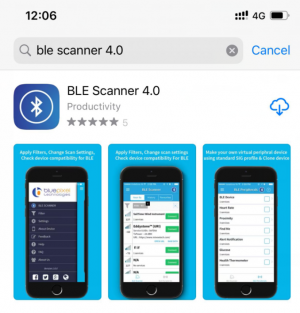

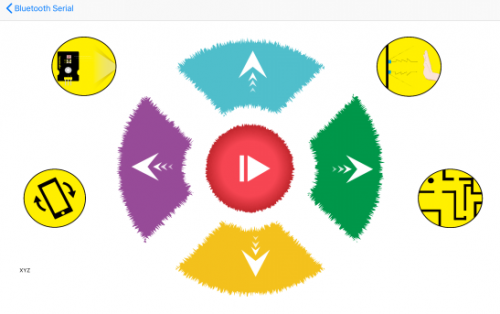

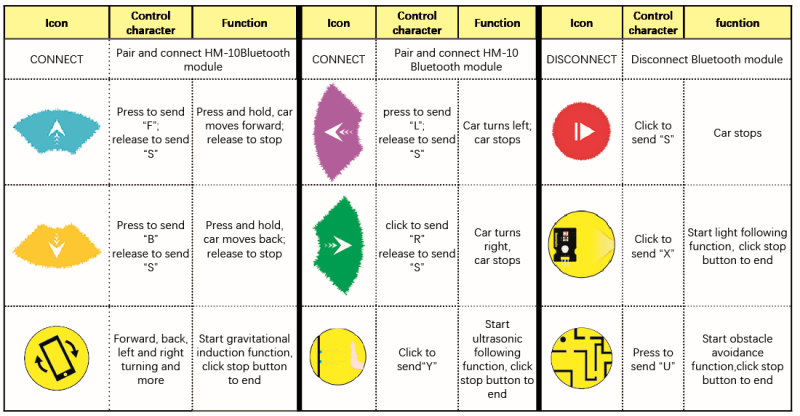

(6)Download APP

Allow APP to access “location” in settings of your cellphone when connecting to Bluetooth module.

The code is reading the received signal, and we also need a stuff to send signal. In this project, we send signal to control robot car via cellphone.

Then we need to download the APP.

1.For iOS system

Enter APP STORE to search BLE Scanner 4.0, then download it.

2.For Android system

Enter Google Play to find out BLE Scanner, then download.

And allow APP to access“location”, you could enable “location”in settings of your cellphone.

- 3.After installation, open App and enable “Location and Bluetooth” permission.

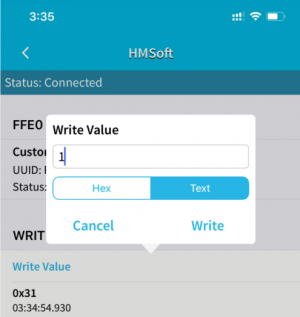

- 4.We take iOS version as example. The operation method of Android version is almost same as it.

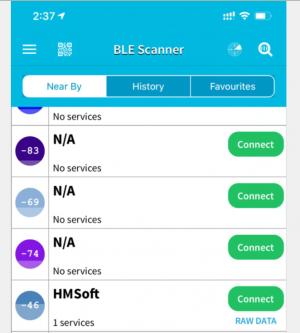

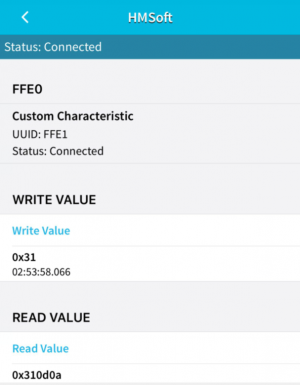

- 5.Scan Bluetooth module to get Bluetooth BLE 4.0. Its name is HMSoft.

Then click“connect”to link with Bluetooth and use it.

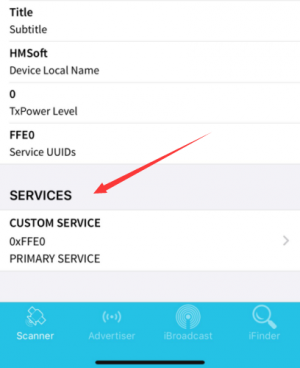

6. After connecting to HMSoft, click it to get multiple options, such as device information, access permission, general and custom service. Choose “CUSTOM SERVICE”

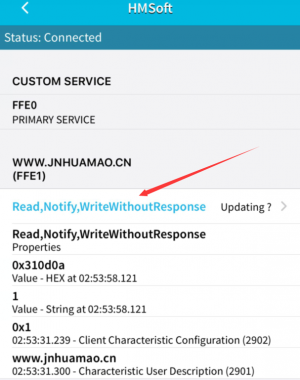

7.Then pop up the following page

8. Click(Read,Notify,WriteWithoutResponse)to enter the following page

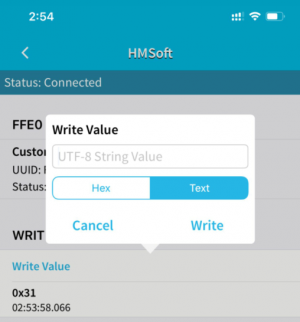

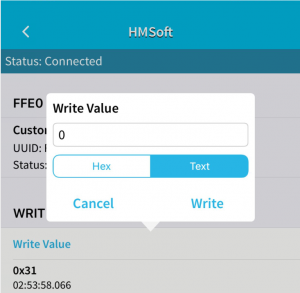

9.Click Write Value, appear the interface to enter HEX or Text.

10.Open the serial monitor on Arduino,enter a 0 or other character at Text interface.

Then click“Write”, open serial monitor to view if there is a “0” signal

(7)Code Explanation

Serial.available() : The current rest characters when return to buffer area. Generally, this function is used to judge if there is data in buffer. When Serial.available()>0, it means that serial receives the data and can be read

Serial.read():Read a data of a Byte in buffer of serial port, for instance, device sends data to Arduino via serial port, then we could read data by “Serial.read()”

(8)Extension Practice

We could send a command via cellphone to turn on and off a LED.

D10 is connected to a LED, as shown below:

/*

keyestudio Mini Tank Robot v2.0

lesson 7.2

Bluetooth

http://www.keyestudio.com

*/

int ledpin=11;

void setup()

{Serial.begin(9600);

pinMode(ledpin,OUTPUT);

}

void loop()

{ int i;

if (Serial.available())

{i=Serial.read();

Serial.println("DATA RECEIVED:");

if(i=='1')

{ digitalWrite(ledpin,1);

Serial.println("led on");

}

if(i=='0')

{ digitalWrite(ledpin,0);

Serial.println("led off");

}}}//*******************************************

Click “Write” on APP, when you enter 1, LED will be on, when you input 0, LED will be off. (Remember to remove the Bluetooth module after finishing experiment, otherwise, burning code will be affected)

Project 8: Motor Driving and Speed Control

(1) Description

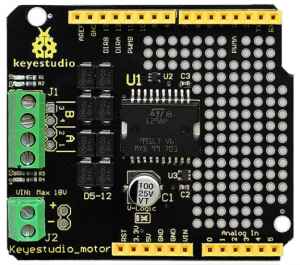

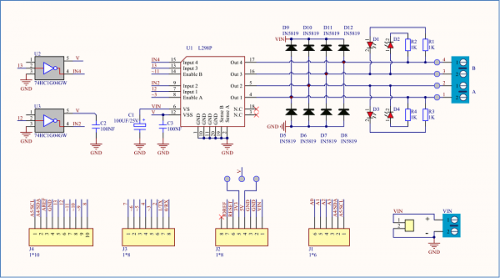

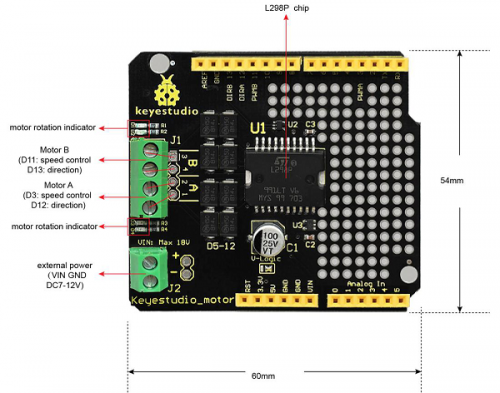

There are many ways to drive the motor. Our tank robot uses the most commonly used L298P solution. L298P is an excellent high-power motor driver IC produced by STMicroelectronics. It can directly drive DC motors, two-phase and four-phase stepping motors. The driving current up to 2A, and output terminal of motor adopts eight high-speed Schottky diodes as protection.

We designed a shield based on the circuit of L298p.

The stacked design reduces the technical difficulty of using and driving the motor.

(2)Specification

Circuit Diagram for L298P Board

- 1)Logic part input voltage: DC5V

- 2)Driving part input voltage: DC 7-12V

- 3)Logic part working current: <36mA

- 4)Driving part working current: <2A

- 5)Maximum power dissipation: 25W (T=75℃)

- 6)Working temperature: -25℃~+130℃

- 7)Control signal input level: high level 2.3V<Vin<5V, low level -0.3V<Vin<1.5V

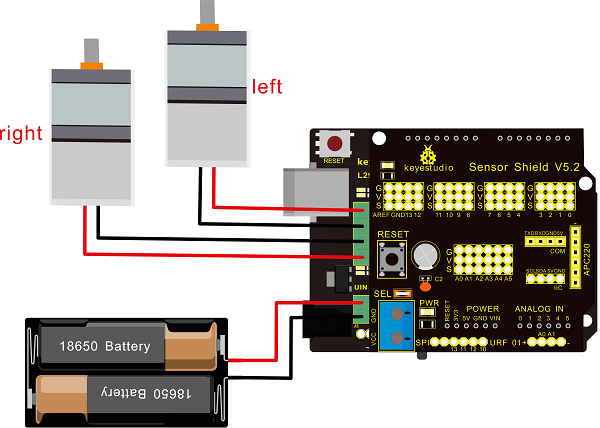

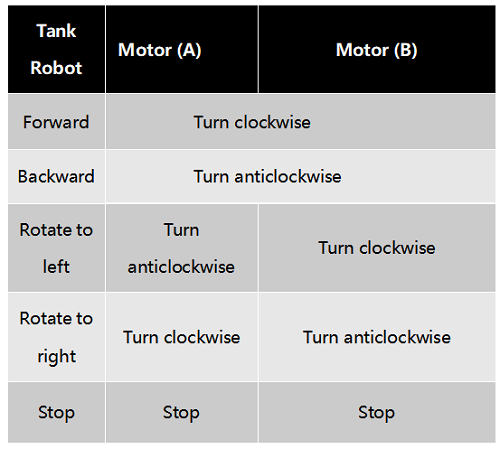

(3)Drive Robot to Move

Through the above circuit diagram, the direction pin of A motor is D12, and speed pin is D3; D13 is the direction pin of B motor, D11 is speed pin.

We know how to control digital ports according to the following chart.

PWM decides 2 motors to turn so as to drive robot car. The PWM value is in the range of 0-255, the larger the number, the faster the motor rotates.

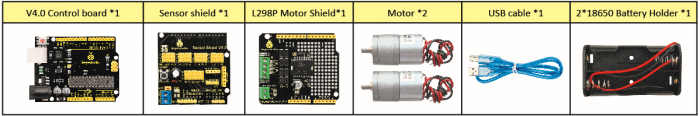

(4)Equipment

(5)Connection Diagram

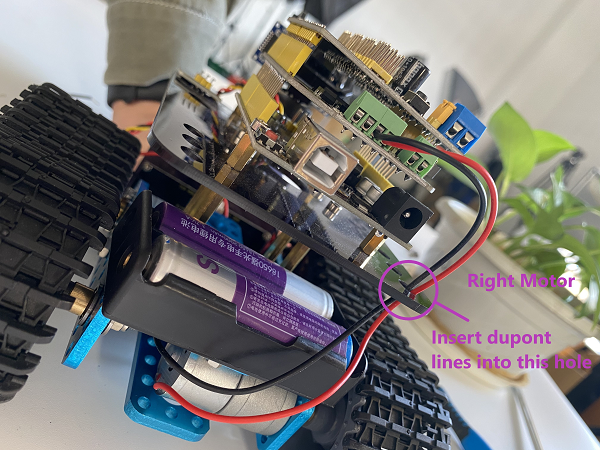

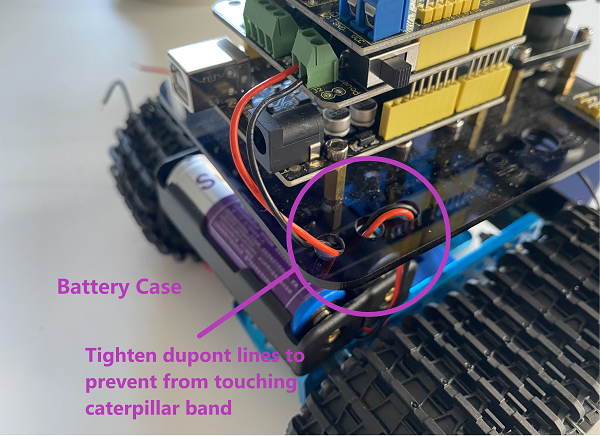

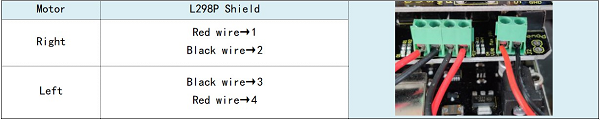

Note: the 4Pin terminal block is marked with silkscreen 1234. The red line of right rear motor is connected to terminal 1, black line is linked with end 2. The red line of left front motor is attached to terminal 3, black line is linked with port 4.

(6)Test Code

/*

keyestudio Mini Tank Robot v2.0

lesson 8.1

motor driver

http://www.keyestudio.com

*/

#define ML_Ctrl 13 //define the direction control pin of left motor

#define ML_PWM 11 //define the PWM control pin of left motor

#define MR_Ctrl 12 //define direction control pin of right motor

#define MR_PWM 3 // define the PWM control pin of right motor

void setup()

{

pinMode(ML_Ctrl, OUTPUT);//define direction control pin of left motor as output

pinMode(ML_PWM, OUTPUT);//define PWM control pin of left motor as output

pinMode(MR_Ctrl, OUTPUT);//define direction control pin of right motor as output.

pinMode(MR_PWM, OUTPUT);//define the PWM control pin of right motor as output

}

void loop()

{

digitalWrite(ML_Ctrl,LOW);//set the direction control pin of left motor to LOW

analogWrite(ML_PWM,200);//set the PWM control speed of left motor to 200

digitalWrite(MR_Ctrl,LOW);//set the direction control pin of right motor to LOW

analogWrite(MR_PWM,200);//set the PWM control speed of right motor to 200

//front

delay(2000);//delay in 2s

digitalWrite(ML_Ctrl,HIGH);//set the direction control pin of left motor to HIGH

analogWrite(ML_PWM,200);//set the PWM control speed of left motor to 200

digitalWrite(MR_Ctrl,HIGH);//set the direction control pin of right motor to HIGH

analogWrite(MR_PWM,200);//set the PWM control speed of right motor to 200

//back

delay(2000);//delay in 2s

digitalWrite(ML_Ctrl,HIGH);//set the direction control pin of left motor to HIGH

analogWrite(ML_PWM,200);//set the PWM control speed of left motor to 200

digitalWrite(MR_Ctrl,LOW);//set the direction control pin of right motor to LOW

analogWrite(MR_PWM,200);//set the PWM control speed of right motor to 200

//left

delay(2000);//delay in 2s

digitalWrite(ML_Ctrl,LOW);//set the direction control pin of left motor to LOW

analogWrite(ML_PWM,200);//set the PWM control speed of left motor to 200

digitalWrite(MR_Ctrl,HIGH);//set the direction control pin of right motor to HIGH

analogWrite(MR_PWM,200);//set the PWM control speed of right motor to 200

//right

delay(2000);//delay in 2s

analogWrite(ML_PWM,0);//set the PWM control speed of left motor to 0

analogWrite(MR_PWM,0);//set the PWM control speed of right motor to 0

//stop

delay(2000);//delay in 2s

}//*****************************************

(7)Test Result

Hook up by connection diagram, upload code and power on, smart car goes forward and back for 2s, turns left and right for 2s, stops for 2s and alternately.

(8) Code Explanation

digitalWrite(ML_Ctrl,LOW): the rotation direction of motor is decided by the high/low level and and the pins that decide rotation direction are general pins.

analogWrite(ML_PWM,200): the speed of motor is regulated by PWM, The speed of motor is regulated by PWM, and the pins that decide the speed of motor have to be PWM pins.

(9)Extension Practice

Hook up in same way

/*

keyestudio Mini Tank Robot v2.0

lesson 8.2

motor driver pwm

http://www.keyestudio.com

*/

#define ML_Ctrl 13 //define the direction control pin of left motor

#define ML_PWM 11 //define the PWM control pin of left motor

#define MR_Ctrl 12 //define the control pin of right motor

#define MR_PWM 3 //define the PWM control pin of right motor

void setup()

{ pinMode(ML_Ctrl, OUTPUT);//define the direction control pin of left motor as OUTPUT

pinMode(ML_PWM, OUTPUT);//define the PWM control pin of left motor as OUTPUT

pinMode(MR_Ctrl, OUTPUT);//define the direction control pin of right motor as OUTPUT

pinMode(MR_PWM, OUTPUT);//define the PWM control pin of right motor as OUTPUT

}

void loop()

{ digitalWrite(ML_Ctrl,LOW);//Set direction control pin of left motor to LOW

analogWrite(ML_PWM,100);// Set the PWM control speed of left motor to 100

digitalWrite(MR_Ctrl,LOW);//Set the direction control pin of right motor to LOW

analogWrite(MR_PWM,100);//Set the PWM control speed of right motor to 100

//front

delay(2000);//define 2s

digitalWrite(ML_Ctrl,HIGH);//Set direction control pin of left motor to HIGH level

analogWrite(ML_PWM,100);//Set the PWM control speed of left motor to 100

digitalWrite(MR_Ctrl,HIGH);//Set direction control pin of right motor to HIGH level

analogWrite(MR_PWM,100);//Set the PWM control speed of right motor to 100

//back

delay(2000);//define 2s

digitalWrite(ML_Ctrl,HIGH);//Set direction control pin of left motor to HIGH level

analogWrite(ML_PWM,100);//Set the PWM control speed of left motor to 100

digitalWrite(MR_Ctrl,LOW);//Set direction control pin of right motor to LOW level

analogWrite(MR_PWM,100);//Set the PWM control speed of right motor to 100

//left

delay(2000);//define 2s

digitalWrite(ML_Ctrl,LOW);//set the direction control pin of left motor to LOW

analogWrite(ML_PWM,100);//set the PWM control speed of left motor to 200

digitalWrite(MR_Ctrl,HIGH);//set the direction control pin of right motor to HIGH

analogWrite(MR_PWM,100);//set the PWM control speed of right motor to 100

//right

delay(2000);//define 2s

analogWrite(ML_PWM,0);//set the PWM control speed of left motor to 0

analogWrite(MR_PWM,0);// set the PWM control speed of right motor to 0

//stop

delay(2000);//define 2s

}//******************************************************************

Upload code successfully, the motors rotate faster.

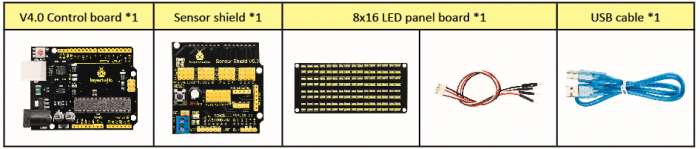

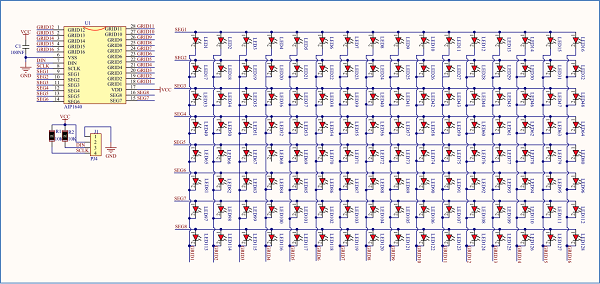

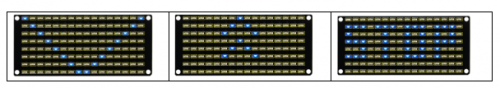

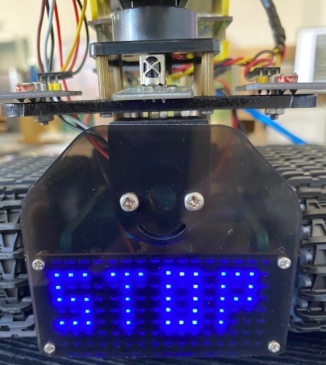

Project 9: LED Expression Panel

(1)Description

If we add an expression panel to the robot, it will be amazing. Keyestudio's 8*16 dot matrix can meet your requirements. You can create facial expressions, patterns or other interesting displays yourself. 8*16 LED light board comes with 128 LEDs. The data of the microprocessor (arduino) communicates with the AiP1640 through the two-wire bus interface, so as to control the 128 LEDs on the module, which produce the patterns you need on dot matrix. To facilitate wiring, we also provide a HX-2.54 4Pin wiring.

(2)Specification

- Working voltage: DC 3.3-5V

- Power loss: 400mW

- Oscillation frequency: 450KHz

- Drive current: 200mA

- Working temperature: -40~80℃

- Communication method: two-wire bus

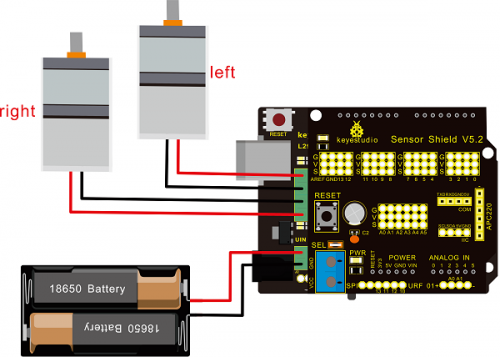

(3)Equipment

(4)8*16 Dot Matrix Display

Circuit Graphic

The principle of 8*16 dot matrix:

How to control each led light of 8*16 dot matrix? We know that a byte has 8 bits, each bit is 0 or 1. When a bit is 0, turn off LED and when a bit is 0, turn on LED.

Thereby, one byte can control the LED in a row of dot matrix, so 16 bytes can control 16 columns of led lights, that is, 8*16 dot matrix.

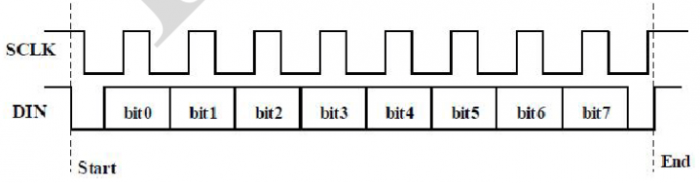

Interface Description and Communication Protocol:

The data of the microprocessor (arduino) communicates with the AiP1640 through the two-wire bus interface.

The communication protocol diagram is shown below:

(SCLK) is SCL, (DIN) is SDA:

①The starting condition for data input: SCL is high level and SDA changes from high to low.

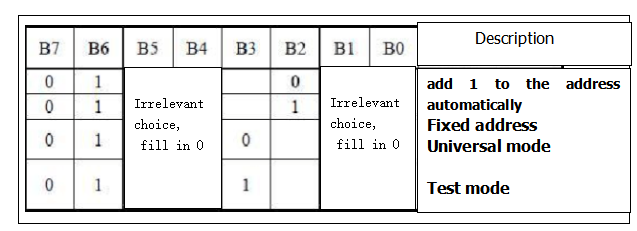

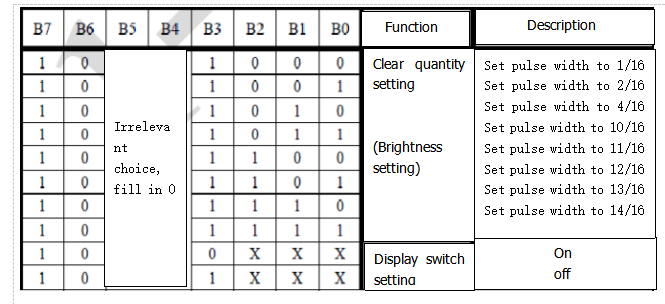

②For data command setting, there are methods as shown in the figure below.

In our sample program, select the way to add 1 to the address automatically, the binary value is 0100 0000 and the corresponding hexadecimal value is 0x40.

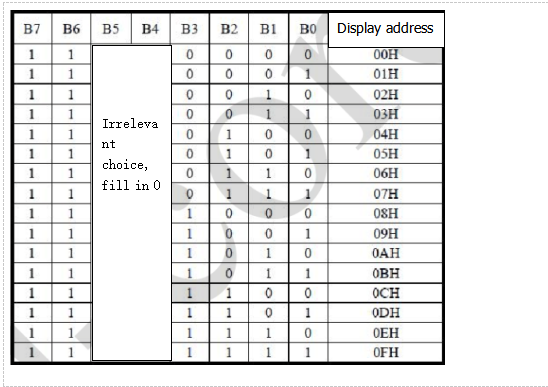

③For address command setting, the address can be selected as shown below. The first 00H is selected in our sample program, and the binary number 1100 0000 corresponds to the hexadecimal 0xc0

- ④The requirement for data input is that SCL is high level when inputting data, the signal on SDA must remain unchanged. Only when the clock signal on SCL is low level, the signal on SDA can be altered. The data input is low-order first, high-order is behind

- ⑤ The condition to end data transmission is that when SCL is low, SDA is low, and when SCL is high, the SDA level also becomes high.

- ⑥ Display control, set different pulse width, the pulse width can be selected as shown below

- In the example, we choose pulse width 4/16, and the hexadecimal corresponds to 1000 1010 is 0x8A

4. Introduction for Modulus Tool

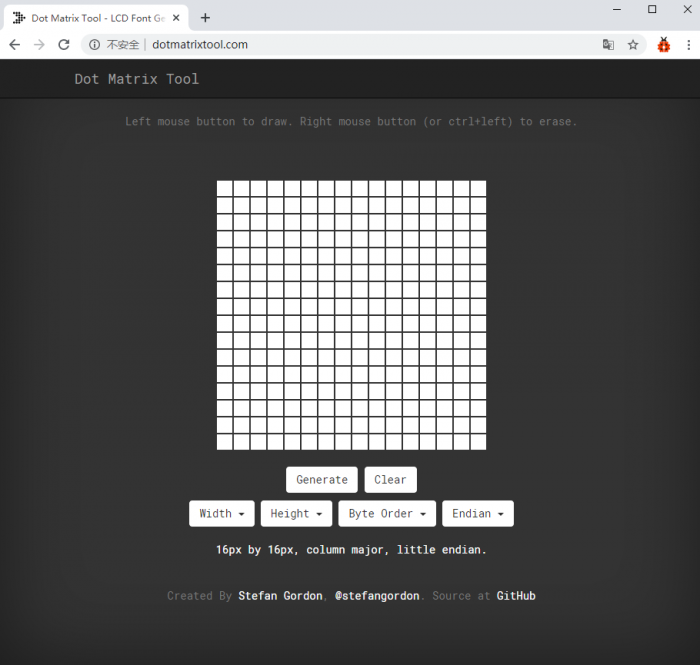

The online version of dot matrix modulus tool: http://dotmatrixtool.com/#

①Open links to enter the following page.

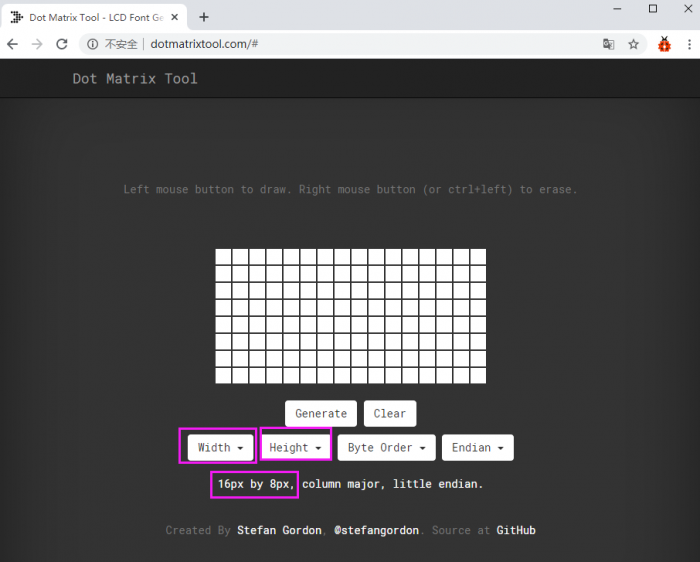

②The dot matrix is 8*16 in this project, so set the height to 8, width to 16, as shown below.

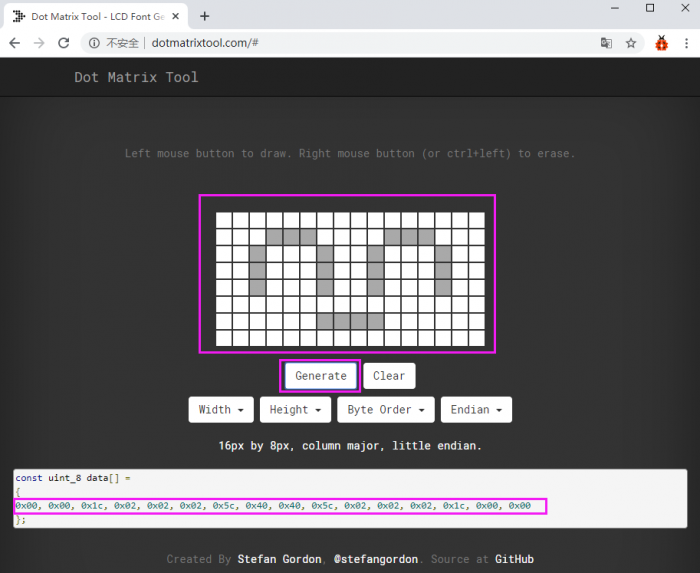

③ Generate hexadecimal data from the pattern As shown below, press the left mouse button to select, the right button to cancel, draw the pattern you want, click Generate, and the hexadecimal data we need will be produced.

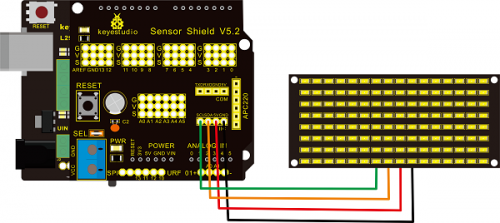

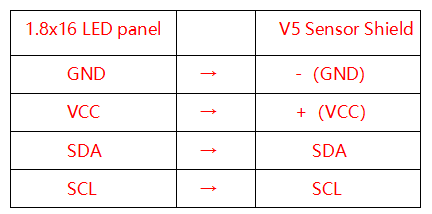

(5)Connection Diagram

Wiring note: The GND, VCC, SDA, and SCL of the 8x16 LED panel are respectively connected to -(GND), + (VCC), A4 and A5 of the keyestudio sensor expansion board for two-wire serial communication. (Note: This pin is connected to arduino IIC, but this module is not IIC communication, it can be linked with any two pins.)

(6)Test Code

The code that shows smile face

/*

keyestudio Mini Tank Robot v2.0

lesson 9.1

Matrix face

http://www.keyestudio.com

*/

//the data of smiley from modulus tool

unsigned char smile[] = {0x00, 0x00, 0x1c, 0x02, 0x02, 0x02, 0x5c, 0x40, 0x40, 0x5c, 0x02, 0x02, 0x02, 0x1c, 0x00, 0x00};

#define SCL_Pin A5 //Set clock pin to A5

#define SDA_Pin A4 //Set data pin to A4

void setup(){

//Set pin to output

pinMode(SCL_Pin,OUTPUT);

pinMode(SDA_Pin,OUTPUT);

//clear the display

//matrix_display(clear);

}

void loop(){

matrix_display(smile); // display smile face

}

// the function for dot matrix display

void matrix_display(unsigned char matrix_value[])

{

IIC_start(); // use the function of the data transmission start condition

IIC_send(0xc0); //select address

for(int i = 0;i < 16;i++) //pattern data has 16 bits

{

IIC_send(matrix_value[i]); //convey the pattern data

}

IIC_end(); //end the transmission of pattern data

IIC_start();

IIC_send(0x8A); //display control, set pulse width to 4/16 s

IIC_end();

}

//the condition to start conveying data

void IIC_start()

{

digitalWrite(SCL_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,LOW);

delayMicroseconds(3);

}

//Convey data

void IIC_send(unsigned char send_data)

{

for(char i = 0;i < 8;i++) //Each byte has 8 bits 8bit for every character

{

digitalWrite(SCL_Pin,LOW); // pull down clock pin SCL_Pin to change the signal of SDA

delayMicroseconds(3);

if(send_data & 0x01) //set high and low level of SDA_Pin according to 1 or 0 of every bit

{

digitalWrite(SDA_Pin,HIGH);

}

else

{

digitalWrite(SDA_Pin,LOW);

}

delayMicroseconds(3);

digitalWrite(SCL_Pin,HIGH); //pull up the clock pin SCL_Pin to stop transmission

delayMicroseconds(3);

send_data = send_data >> 1; // detect bit by bit, shift the data to the right by one

}

}

//The sign of ending data transmission

void IIC_end()

{

digitalWrite(SCL_Pin,LOW);

delayMicroseconds(3);

digitalWrite(SDA_Pin,LOW);

delayMicroseconds(3);

digitalWrite(SCL_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,HIGH);

delayMicroseconds(3);

}

//******************************************************

(7)Test Result

Wire according to connection diagram. The DIP switch is dialed to right end and power on, the smile face appears on dot matrix.

(8)Extension Practice

We use the modulo tool (http://dotmatrixtool.com/#)to make the dot matrix alternately display start, go front and stop patterns then clear the patterns, the time interval is 2000 milliseconds.

Get the graphical code to be displayed via modulus tool

- Start:

- 0x01,0x02,0x04,0x08,0x10,0x20,0x40,0x80,0x80,0x40,0x20,0x10,0x08,0x04,0x02,0x01

- Go front:

- 0x00,0x00,0x00,0x00,0x00,0x24,0x12,0x09,0x12,0x24,0x00,0x00,0x00,0x00,0x00,0x00

- Go back:

- 0x00,0x00,0x00,0x00,0x00,0x24,0x48,0x90,0x48,0x24,0x00,0x00,0x00,0x00,0x00,0x00

- Turn left:

- 0x00,0x00,0x00,0x00,0x00,0x00,0x44,0x28,0x10,0x44,0x28,0x10,0x44,0x28,0x10,0x00

- Turn left:

- 0x00,0x10,0x28,0x44,0x10,0x28,0x44,0x10,0x28,0x44,0x00,0x00,0x00,0x00,0x00,0x00

- Stop:

- 0x2E,0x2A,0x3A,0x00,0x02,0x3E,0x02,0x00,0x3E,0x22,0x3E,0x00,0x3E,0x0A,0x0E,0x00

- Clear the displayed code:0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00

The code that the multiple patterns shift:

/* keyestudio Mini Tank Robot v2.0

lesson 9.2

Matrix loop

http://www.keyestudio.com

*/

//Array, used to store the data of the pattern, can be calculated by yourself or obtained from the modulus tool

unsigned char start01[] =

{0x01,0x02,0x04,0x08,0x10,0x20,0x40,0x80,0x80,0x40,0x20,0x10,0x08,0x04,0x02,0x01};

unsigned char front[] =

{0x00,0x00,0x00,0x00,0x00,0x24,0x12,0x09,0x12,0x24,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char back[] =

{0x00,0x00,0x00,0x00,0x00,0x24,0x48,0x90,0x48,0x24,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char left[] =

{0x00,0x00,0x00,0x00,0x00,0x00,0x44,0x28,0x10,0x44,0x28,0x10,0x44,0x28,0x10,0x00};

unsigned char right[] =

{0x00,0x10,0x28,0x44,0x10,0x28,0x44,0x10,0x28,0x44,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char STOP01[] =

{0x2E,0x2A,0x3A,0x00,0x02,0x3E,0x02,0x00,0x3E,0x22,0x3E,0x00,0x3E,0x0A,0x0E,0x00};

unsigned char clear[] =

{0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00};

#define SCL_Pin A5 //Set clock pin to A5

#define SDA_Pin A4 //Set data pin to A4

void setup(){

//Set pins to output

pinMode(SCL_Pin,OUTPUT);

pinMode(SDA_Pin,OUTPUT);

//Clear the display

matrix_display(clear);

}

void loop(){

matrix_display(start01); // Display start pattern

delay(2000);

matrix_display(front); //Front pattern

delay(2000);

matrix_display(STOP01); //Stop pattern

delay(2000);

matrix_display(clear); //Clear the display Clear the screen

delay(2000);

}

// This function is used to display of dot matrix

void matrix_display(unsigned char matrix_value[])

{

IIC_start(); //call the function that data transmission start

IIC_send(0xc0); //Choose address

for(int i = 0;i < 16;i++) //pattern data has 16 bits

{

IIC_send(matrix_value[i]); //data to convey patterns

}

IIC_end(); //end the transmission of pattern dataEnd

IIC_start();

IIC_send(0x8A); //display control, set pulse width to 4/16

IIC_end();

}

//The condition starting to transmit data

void IIC_start()

{

digitalWrite(SCL_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,LOW);

delayMicroseconds(3);

}

//Convey data

void IIC_send(unsigned char send_data)

{

for(char i = 0;i < 8;i++) //Each byte has 8 bits

{

digitalWrite(SCL_Pin,LOW); //pull down clock pin SCL Pin to change the signals of SDA

delayMicroseconds(3);

if(send_data & 0x01) //set high and low level of SDA_Pin according to 1 or 0 of every bit

{

digitalWrite(SDA_Pin,HIGH);

}

else

{

digitalWrite(SDA_Pin,LOW);

}

delayMicroseconds(3);

digitalWrite(SCL_Pin,HIGH); //pull up clock pin SCL_Pin to stop transmitting data

delayMicroseconds(3);

send_data = send_data >> 1; //detect bit by bit, so shift the data right by one

}}

//The sign that data transmission ends

void IIC_end()

{

digitalWrite(SCL_Pin,LOW);

delayMicroseconds(3);

digitalWrite(SDA_Pin,LOW);

delayMicroseconds(3);

digitalWrite(SCL_Pin,HIGH);

delayMicroseconds(3);

digitalWrite(SDA_Pin,HIGH);

delayMicroseconds(3);}

//*****************************************************

Upload code on development board, 8*16 dot matrix display go front and back and stop patterns, alternately.

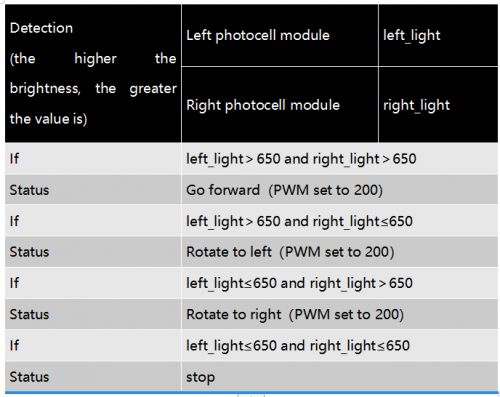

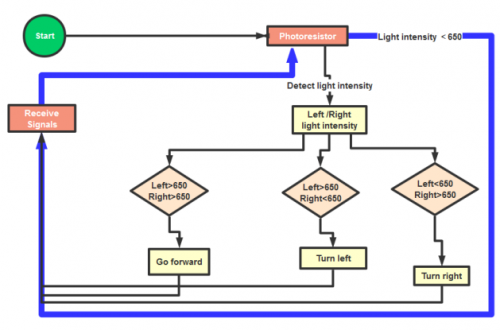

Project 10: Light Follow Robot

(1)Description

We’ve introduce how to use various sensors, modules.

In this lesson, we combine with hardware knowledge -- photoresistor module, motor driving, to build a light-following robot!

Just need to use 2 photoresistor modules to detect the light intensity at the both side of robot. Read the analog value to rotate the 2 motors, thus drive the tank robot run.

The specific logic of light following robot is shown as the table below:

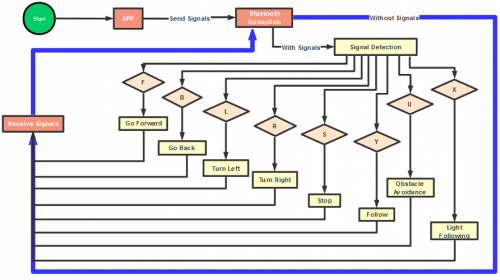

We make a flow chart based on the above logic table, as shown below:

(2)Connection Diagram

Hook-up Attention:

The 4Pin terminal block is marked with silkscreen 1234. The red line of right rear motor is connected to terminal 1, black line is linked with end 2. The red line of left front motor is attached to terminal 3, black line is linked with port 4.

(3)Test Code

/*

keyestudio Mini Tank Robot v2.0

lesson 10

Light-following tank

http://www.keyestudio.com

*/

#define light_L_Pin A1 //define the pin of left photo resistor

#define light_R_Pin A2 //define the pin of right photo resistor

#define ML_Ctrl 13 //define the direction control pin of left motor

#define ML_PWM 11 //define the PWM control pin of left motor

#define MR_Ctrl 12 //define the direction control pin of right motor

#define MR_PWM 3 //define the PWM control pin of right motor

int left_light;

int right_light;

void setup(){

Serial.begin(9600);

pinMode(light_L_Pin, INPUT);

pinMode(light_R_Pin, INPUT);

pinMode(ML_Ctrl, OUTPUT);

pinMode(ML_PWM, OUTPUT);

pinMode(MR_Ctrl, OUTPUT);

pinMode(MR_PWM, OUTPUT);

}

void loop(){

left_light = analogRead(light_L_Pin);

right_light = analogRead(light_R_Pin);

Serial.print("left_light_value = ");

Serial.println(left_light);

Serial.print("right_light_value = ");

Serial.println(right_light);

if (left_light > 650 && right_light > 650) //the value detected photo resistor,go front

{

Car_front();

}

else if (left_light > 650 && right_light <= 650) //the value detected photo resistor,turn left

{

Car_left();

}

else if (left_light <= 650 && right_light > 650) //the value detected photo resistor,turn right

{

Car_right();

}

else //other situations, stop

{

Car_Stop();

}

}

void Car_front()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,200);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,200);

}

void Car_left()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,200);

digitalWrite(ML_Ctrl,HIGH);

analogWrite(ML_PWM,200);

}

void Car_right()

{

digitalWrite(MR_Ctrl,HIGH);

analogWrite(MR_PWM,200);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,200);

}

void Car_Stop()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,0);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,0);

}

//****************************************************************

(4)Test Result

Upload code on keyestudio V4.0 development board, DIP switch is dialed to right end and power on, the smart robot follows light to move.

Project 11: Ultrasonic Avoid Tank

(1)Description

In this program, the ultrasonic sensor detects the distance of obstacle to send signals that control the robot car. Next, let’s show you how to make an obstacle avoidance car.

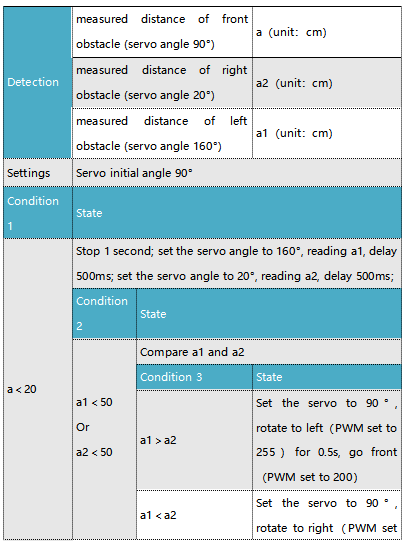

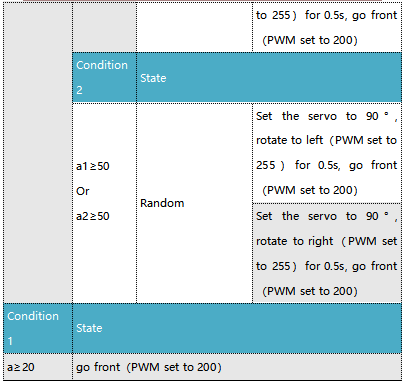

The specific logic of ultrasonic avoiding robot is as shown below:

(2)Flow chart

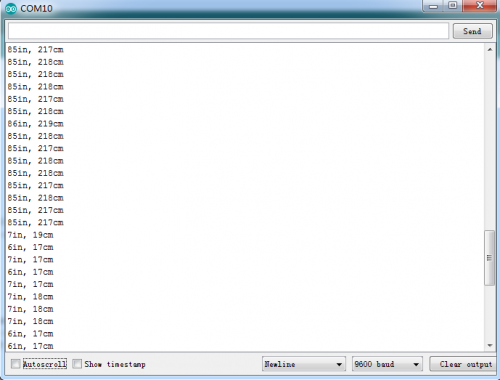

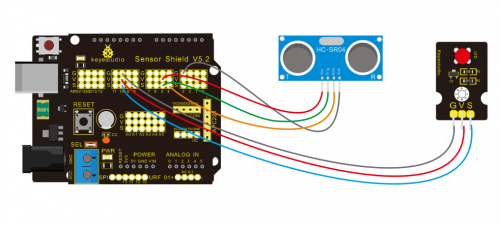

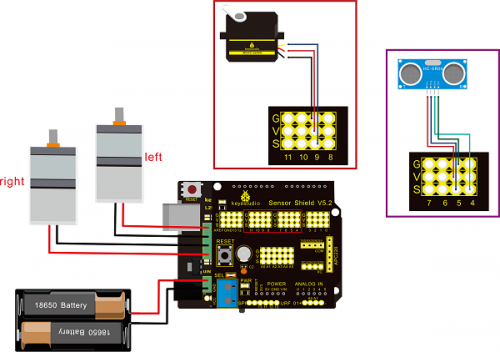

(3)Connection Diagram:

Note: “-”、“+” and “S” pins of servo are respectively attached to G(GND), V(VCC)and D9 of expansion board. The VCC, Trig, Echo and Gnd of ultrasonic sensor are linked with 5v(V), 5(S), Echo and Gnd(G) of expansion board.

(4)Test Code:

/*

keyestudio Mini Tank Robot v2.0

lesson 11

ultrasonic_avoid_tank

http://www.keyestudio.com

*/

int random2;

int a;

int a1;

int a2;

#define ML_Ctrl 13 //define the direction control pin of left motor

#define ML_PWM 11 //define PWM control pin of left motor

#define MR_Ctrl 12 //define the direction control pin of right motor

#define MR_PWM 3 //define PWM control pin of right motor

#define Trig 5 //ultrasonic trig Pin

#define Echo 4 //ultrasonic echo Pin

int distance;

#define servoPin 9 //servo Pin

int pulsewidth;

/************the function to run motor**************/

void Car_front()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,200);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,200);

}

void Car_back()

{

digitalWrite(MR_Ctrl,HIGH);

analogWrite(MR_PWM,200);

digitalWrite(ML_Ctrl,HIGH);

analogWrite(ML_PWM,200);

}

void Car_left()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,255);

digitalWrite(ML_Ctrl,HIGH);

analogWrite(ML_PWM,255);

}

void Car_right()

{

digitalWrite(MR_Ctrl,HIGH);

analogWrite(MR_PWM,255);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,255);

}

void Car_Stop()

{

digitalWrite(MR_Ctrl,LOW);

analogWrite(MR_PWM,0);

digitalWrite(ML_Ctrl,LOW);

analogWrite(ML_PWM,0);

}

//The function to control servo

void procedure(int myangle) {

for (int i = 0; i <= 50; i = i + (1)) {

pulsewidth = myangle * 11 + 500;

digitalWrite(servoPin,HIGH);

delayMicroseconds(pulsewidth);

digitalWrite(servoPin,LOW);

delay((20 - pulsewidth / 1000));

}

}

//The function to control ultrasonic sensor

float checkdistance() {

digitalWrite(Trig, LOW);

delayMicroseconds(2);

digitalWrite(Trig, HIGH);

delayMicroseconds(10);

digitalWrite(Trig, LOW);

float distance = pulseIn(Echo, HIGH) / 58.00; //58.20, that is, 2*29.1=58.2

delay(10);

return distance;

}

//****************************************************************

void setup(){

pinMode(servoPin, OUTPUT);

procedure(90); //set servo to 90°

pinMode(Trig, OUTPUT);

pinMode(Echo, INPUT);

pinMode(ML_Ctrl, OUTPUT);

pinMode(ML_PWM, OUTPUT);

pinMode(MR_Ctrl, OUTPUT);

pinMode(MR_PWM, OUTPUT);

}

void loop(){

random2 = random(1, 100);

a = checkdistance(); //assign the front distance detected by ultrasonic sensor to variable a

if (a < 20) //when the front distance detected is less than 20

{

Car_Stop(); //robot stops

delay(500); //delay in 500ms

procedure(160); //Ultrasonic platform turns left

for (int j = 1; j <= 10; j = j + (1)) { //for statement, the data will be more accurate if ultrasonic sensor detect a few times.

a1 = checkdistance(); //assign the left distance detected by ultrasonic sensor to variable a1

}

delay(300);

procedure(20); //Ultrasonic platform turns right

for (int k = 1; k <= 10; k = k + (1)) {

a2 = checkdistance(); //assign the right distance detected by ultrasonic sensor to variable a2

}

if (a1 < 50 || a2 < 50) //robot will turn to the longer distance side when left or right distance is less than 50cm.

{

if (a1 > a2) //left distance is greater than right side

{

procedure(90); //Ultrasonic platform turns back to right ahead

Car_left(); //robot turns left

delay(500); //turn left for 500ms

Car_front(); //go front

}

else

{

procedure(90);

Car_right(); //robot turns right

delay(500);

Car_front(); //go front

}

}

else //If both side is greater than or equal to 50cm, turn left or right randomly

{

if ((long) (random2) % (long) (2) == 0) //When the random number is even

{

procedure(90);

Car_left(); //tank robot turns left

delay(500);

Car_front(); //go front

}

else

{

procedure(90);

Car_right(); //robot turns right

delay(500);

Car_front(); //go front

}

}

}

else //If the front distance is greater than or equal to 20cm, robot car will go front

{

Car_front(); //go front

}

}

//****************************************************************

(5)Test Result

Upload code successfully, DIP switch is dialed to right end and power on, tank robot goes forward. It can automatically avoid barrier.

Project 12: Ultrasonic Follow Tank

(1)Description

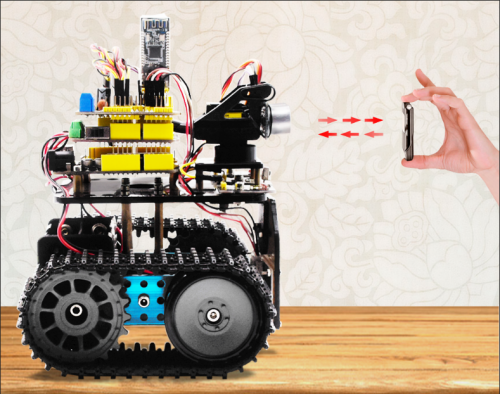

In project 11, we made an obstacle avoidance car. In fact, we only need to alter a test code to transform an obstacle avoidance car into following car. In this lesson, we will make an ultrasonic follow robot. The ultrasonic sensor detects the distance between smart car and the obstacle to drive tank car to move.

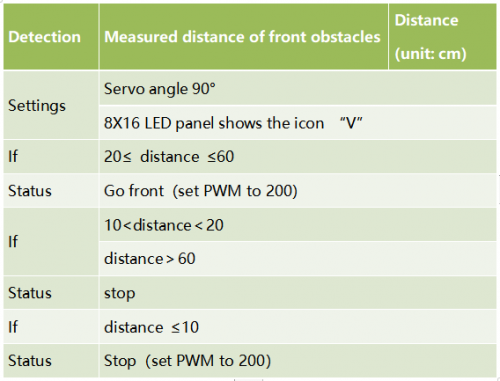

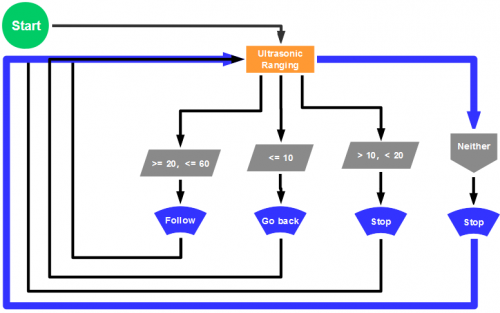

The specific logic of ultrasonic follow robot is as shown below:

(2)Flow chart

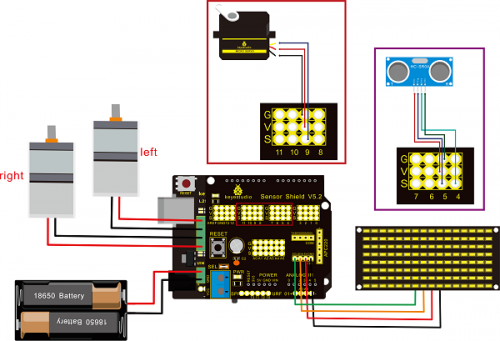

(3)Connection Diagram

Wire-up note:

(4)Test Code

/*

keyestudio Mini Tank Robot v2.0

lesson 12

ultrasonic follow tank

http://www.keyestudio.com

*/

//Array, used to store the data of the pattern, can be calculated by yourself or obtained from the modulus tool

unsigned char start01[] = {0x01,0x02,0x04,0x08,0x10,0x20,0x40,0x80,0x80,0x40,0x20,0x10,0x08,0x04,0x02,0x01};

unsigned char front[] = {0x00,0x00,0x00,0x00,0x00,0x24,0x12,0x09,0x12,0x24,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char back[] = {0x00,0x00,0x00,0x00,0x00,0x24,0x48,0x90,0x48,0x24,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char left[] = {0x00,0x00,0x00,0x00,0x00,0x00,0x44,0x28,0x10,0x44,0x28,0x10,0x44,0x28,0x10,0x00};

unsigned char right[] = {0x00,0x10,0x28,0x44,0x10,0x28,0x44,0x10,0x28,0x44,0x00,0x00,0x00,0x00,0x00,0x00};

unsigned char STOP01[] = {0x2E,0x2A,0x3A,0x00,0x02,0x3E,0x02,0x00,0x3E,0x22,0x3E,0x00,0x3E,0x0A,0x0E,0x00};

unsigned char clear[] = {0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00};

#define SCL_Pin A5 //Set clock pin to A5

#define SDA_Pin A4 //Set data pin to A4

#define ML_Ctrl 13 //define the direction control pin of left motor

#define ML_PWM 11 //define PWM control pin of left motor

#define MR_Ctrl 12 //define the direction control pin of right motor

#define MR_PWM 3 //define PWM control pin of right motor

#define Trig 5 //ultrasonic trig Pin

#define Echo 4 //ultrasonic echo Pin

int distance;

int pulsewidth;

#define servoPin 9 //servo Pin

void setup(){

Serial.begin(9600);

pinMode(SCL_Pin,OUTPUT);

pinMode(SDA_Pin,OUTPUT);

matrix_display(clear); //Clear the display

matrix_display(start01); //display start pattern

pinMode(servoPin, OUTPUT);

procedure(90); //set servo to 90°

pinMode(Trig, OUTPUT);

pinMode(Echo, INPUT);

pinMode(ML_Ctrl, OUTPUT);

pinMode(ML_PWM, OUTPUT);

pinMode(MR_Ctrl, OUTPUT);

pinMode(MR_PWM, OUTPUT);

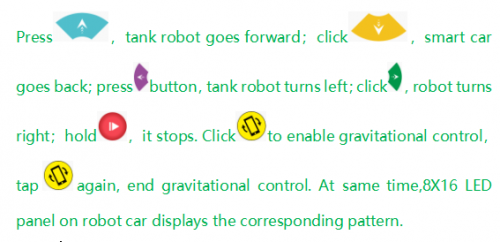

}