Ks0182 keyestudio LED Cube Kit

Ks0182 keyestudio LED Cube Kit

Introduction

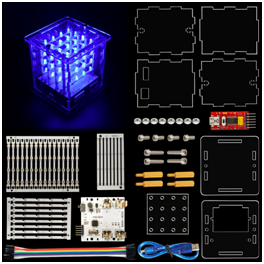

For ARDUINO starters, we’d love to do projects that would blow people’s mind off. But without certain basic knowledge of electronics, we may find it difficult to do complicated projects such as robots, 3D printers etc. This 4x4x4 LED Cube kit we developed is no doubt your best choice.

So what is LED Cube? Well, by the name of it, we can tell it may be a light emitting cube. We use 64 LEDs to solder a 4*4*4 3D-matrix. Each face of the cu¬¬be or should we say each dot of the cube will emit beautiful light.

This 3D LED cube is based on ARDUINO, an open-source environment. So it also has features of open-source and easy-to-use. Even for enthusiasts without solid electronic knowledge, you can make projects that are going to amaze others!

Features

- Adopts 64 blue LEDs

- working voltage: 5V

- working current: 150MA

- power input with built-in voltage step-up circuit

- compatible with ARDUINO open-source hardware

- comes with animations program

- Simple assembly using a PCB frame

- can work off-line (doesn’t require a computer after program is uploaded)

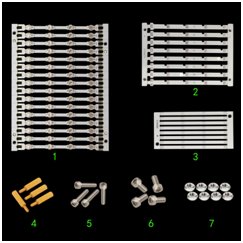

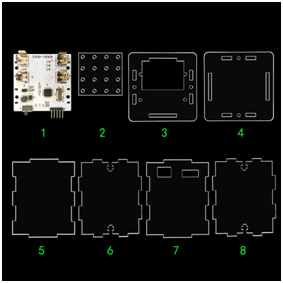

Part list

1. Control panel (1 PCS)

2. Soldering jig (1 PCS)

3. Acrylic chassis (1 PCS)

4. Acrylic crown sheet (1 PCS)

5、6、7、8. Acrylic side plate ,then No. 6 and 8 is the same (4 PCS in total)

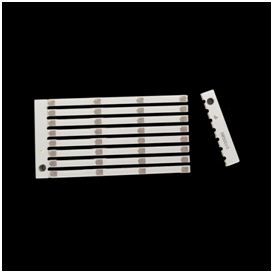

1.Stand horizontal plate(16 PCS)

2.Stand upright column board (8 PCS

3.Horizontal holder board (8 PCS)

4.Copper bush (4 PCS)

5.3*10 inner-hexagon screw(4 PCS)

6.3*6 inner-hexagon screw(4 PCS)

7.3M nut(4 PCS)

'Self-prepare tools:

Soldering iron、Tinny line、Inner-hexagon too

Step by step soldering instructions

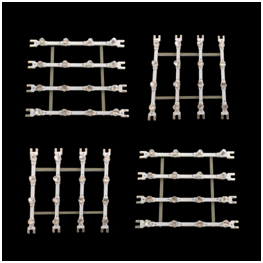

Solder the stand horizontal plates

Unpick the stand horizontal plates as shown above.

Unpick the horizontal holder boards following the previous step.

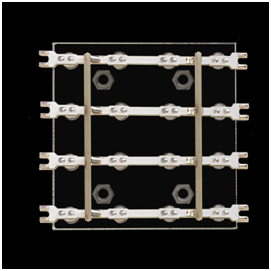

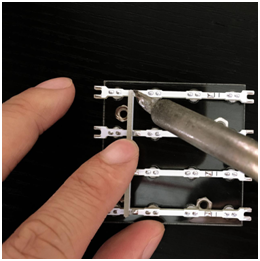

Set four nuts in in the kit as shown above,then put four stand horizontal plates on the soldering jig,and black lines on the stand horizontal plates aims to indicate the place of subsequent soldering holder boards.

Place the soldering jig on four nuts, and then put two horizontal holder board on the stand horizontal plate between black lines, and finally add tin to fix them on eight welding spots by soldering iron.