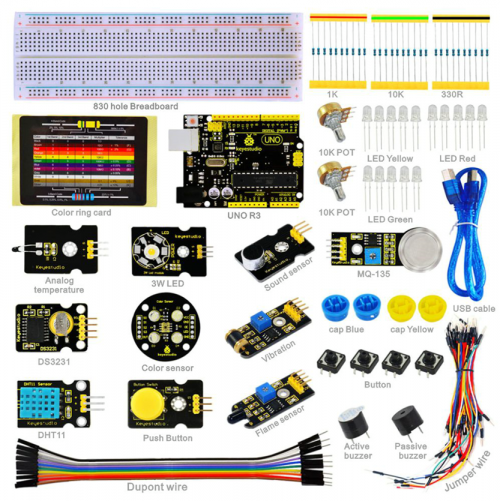

Ks0180 keyestudio Sensor Kit for ARDUINO starters- K3

keyestudio Sensor Kit for ARDUINO starters- K3

Introduction

This keyestudio Sensor Kit is an Arduino stater learning kit developed by Keyes. We provide detailed tutorials for each project or sensor module, including connection diagrams and sample codes, with which you will find it easy for you to complete every experiments. Besides, you can also find video tutorials of this kit on our official website.

Component List

Project details

Project 1: Hello World

Introduction

As for starters, we will begin with something simple. In this project, you only need an Arduino and a USB cable to start the "Hello World!" experiment. This is a communication test of your Arduino and PC, also a primer project for you to have your first try of the Arduino world!

Hardware required

Arduino board *1

USB cable *1

Sample program

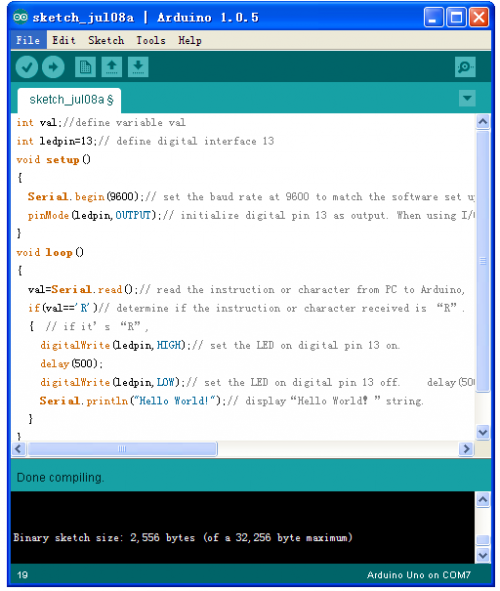

After installing driver for Arduino, let's open Arduino software and compile code that enables Arduino to print "Hello World!" under your instruction. Of course, you can compile code for Arduino to continuously echo "Hello World!" without instruction. A simple If () statement will do the instruction trick. With the onboard LED connected to pin 13, we can instruct the LED to blink first when Arduino gets an instruction and then print "Hello World!”.

int val;//define variable val

int ledpin=13;// define digital interface 13

void setup()

{

Serial.begin(9600);// set the baud rate at 9600 to match the software set up. When connected to a specific device, (e.g. bluetooth), the baud rate needs to be the same with it.

pinMode(ledpin,OUTPUT);// initialize digital pin 13 as output. When using I/O ports on an Arduino, this kind of set up is always needed.

}

void loop()

{

val=Serial.read();// read the instruction or character from PC to Arduino, and assign them to Val.

if(val=='R')// determine if the instruction or character received is “R”.

{ // if it’s “R”,

digitalWrite(ledpin,HIGH);// set the LED on digital pin 13 on.

delay(500);

digitalWrite(ledpin,LOW);// set the LED on digital pin 13 off.

delay(500);

Serial.println("Hello World!");// display“Hello World!”string.

}

}

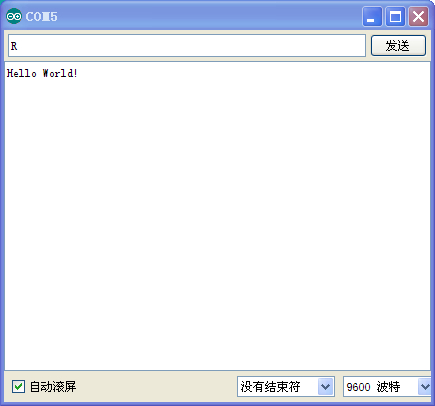

Result

Click serial port monitor,Input R,LED 13 will blink once,PC will receive information from Arduino: Hello World

After you choosing the right port,the experiment should be easy for you!

Project 2: LED blinking

Introduction

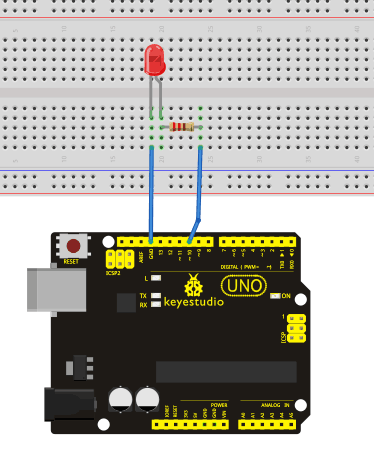

Blinking LED experiment is quite simple. In the "Hello World!" program, we have come across LED. This time, we are going to connect an LED to one of the digital pins rather than using LED13, which is soldered to the board. Except an Arduino and an USB cable, we will need extra parts as below:

Hardware required

Red M5 LED*1

220Ω resistor*1

Breadboard*1

Breadboard jumper wires

Circuit connection

We follow below diagram from the experimental schematic link. Here we use digital pin 10. We connect LED to a 220 ohm resistor to avoid high current damaging the LED.

Sample program

int ledPin = 10; // define digital pin 10.

void setup()

{

pinMode(ledPin, OUTPUT);// define pin with LED connected as output.

}

void loop()

{

digitalWrite(ledPin, HIGH); // set the LED on.

delay(1000); // wait for a second.

digitalWrite(ledPin, LOW); // set the LED off.

delay(1000); // wait for a second

}

Result

After downloading this program, in the experiment, you will see the LED connected to pin 10 turning on and off, with an interval approximately one second. The LED blinking experiment is now complete. Thank you!

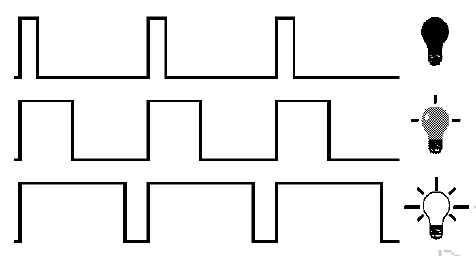

Project 3: PWM

Introduction

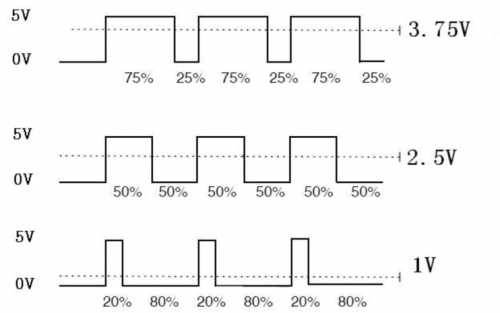

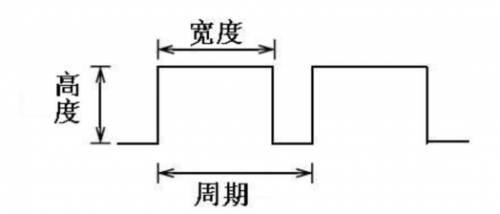

PWM, short for Pulse Width Modulation, is a technique used to encode analog signal level into digital ones. A computer cannot output analog voltage but only digital voltage values such as 0V or 5V. So we use a high resolution counter to encode a specific analog signal level by modulating the duty cycle of PMW. The PWM signal is also digitalized because in any given moment, fully on DC power supply is either 5V (ON), or 0V (OFF). The voltage or current is fed to the analog load (the device that uses the power) by repeated pulse sequence being ON or OFF. Being on, the current is fed to the load; being off, it's not. With adequate bandwidth, any analog value can be encoded using PWM. The output voltage value is calculated via the on and off time. Output voltage = (turn on time/pulse time) * maximum voltage value

PWM has many applications: lamp brightness regulating, motor speed regulating, sound making, etc. The following are the three basic parameters of PMW:

1. The amplitude of pulse width (minimum / maximum)

2. The pulse period (The reciprocal of pulse frequency in 1 second)

3. The voltage level(such as:0V-5V)

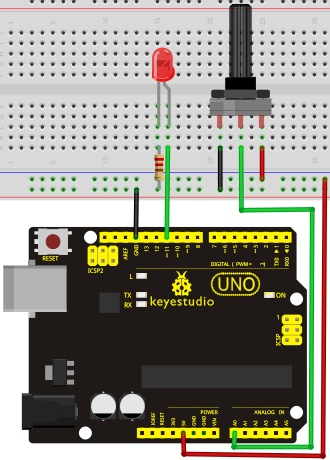

There are 6 PMW interfaces on Arduino, namely digital pin 3, 5, 6, 9, 10, and 11. In previous experiments, we have done "button-controlled LED", using digital signal to control digital pin, also one about potentiometer. This time, we will use a potentiometer to control the brightness of the LED.

Hardware required

Potentiometer module*1

Red M5 LED*1

220Ω resistor

Breadboard*1

Breadboard jumper wires

Circuit connection

The input of potentiometer is analog, so we connect it to analog port, and LED to PWM port. Different PWM signal can regulate the brightness of the LED.

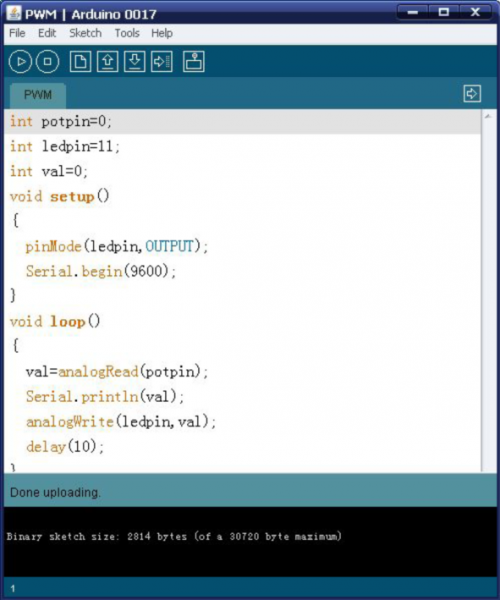

Sample program

In the program compiling process, we will use the analogWrite (PWM interface, analog value) function. In this experiment, we will read the analog value of the potentiometer and assign the value to PWM port, so there will be corresponding change to the brightness of the LED. One final part will be displaying the analog value on the screen. You can consider this as the "analog value reading" project adding the PWM analog value assigning part. Below is a sample program for your reference.

int potpin=0;// initialize analog pin 0

int ledpin=11;//initialize digital pin 11(PWM output)

int val=0;// Temporarily store variables' value from the sensor

void setup()

{

pinMode(ledpin,OUTPUT);// define digital pin 11 as “output”

Serial.begin(9600);// set baud rate at 9600

// attention: for analog ports, they are automatically set up as “input”

}

void loop()

{

val=analogRead(potpin);// read the analog value from the sensor and assign it to val

Serial.println(val);// display value of val

analogWrite(ledpin,val/4);// turn on LED and set up brightness(maximum output of PWM is 255)

delay(10);// wait for 0.01 second

}

Result

After downloading the program, when we rotate the potentiometer knob, we can see changes of the displaying value, also obvious change of the LED brightness on the breadboard.

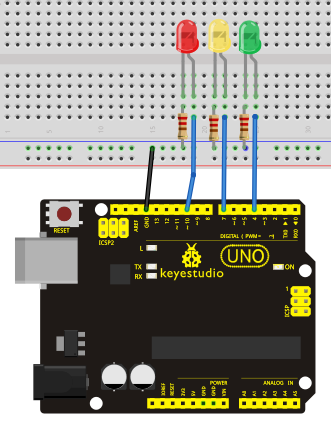

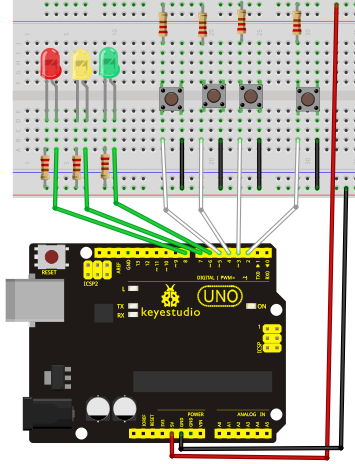

Project 4: Traffic light

Introduction

In the previous program, we have done the LED blinking experiment with one LED. Now, it’s time to up the stakes and do a bit more complicated experiment-traffic lights. Actually, these two experiments are similar. While in this traffic lights experiment, we use 3 LEDs with different color other than 1 LED.

Hardware required

Arduino board *1

USB cable *1

Red M5 LED*1

Yellow M5 LED*1

Green M5 LED*1

220Ω resistor *3

Breadboard*1

Breadboard jumper wires

Circuit connection

Sample program

Since it is a simulation of traffic lights, the blinking time of each LED should be the same with those in traffic lights system. In this program, we use Arduino delay () function to control delay time, which is much simpler than C language.

int redled =10; // initialize digital pin 8.

int yellowled =7; // initialize digital pin 7.

int greenled =4; // initialize digital pin 4.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(greenled, OUTPUT); // set the pin with green LED as “output”

}

void loop()

{

digitalWrite(greenled, HIGH);//// turn on green LED

delay(5000);// wait 5 seconds

digitalWrite(greenled, LOW); // turn off green LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 second

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 second

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 second

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 second

digitalWrite(redled, LOW);// turn off red LED

}

Result

When the uploading process is completed, we can see traffic lights of our own design.

Note: this circuit design is very similar with the one in LED chase effect. The green light will be on for 5 seconds, and then off., followed by the yellow light blinking for 3 times, and then the red light on for 5 seconds, forming a cycle. Cycle then repeats. Experiment is now completed, thank you.

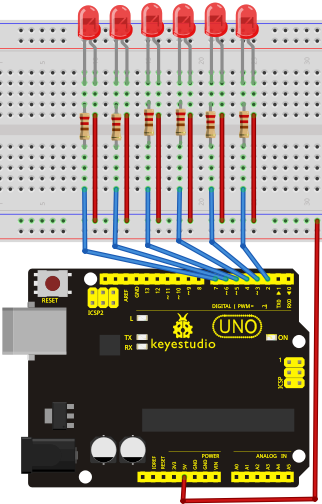

Project 5: LED chasing effect

Introduction

We often see billboards composed of colorful LEDs. They are constantly changing to form various effects. In this experiment, we compile a program to simulate chase effect.

Hardware required

Led *6

220Ω resistor *6

Breadboard jumper wires

Circuit connection

Sample program

int BASE = 2 ; // the I/O pin for the first LED

int NUM = 6; // number of LEDs

void setup()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

pinMode(i, OUTPUT); // set I/O pins as output

}

}

void loop()

{

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, LOW); // set I/O pins as “low”, turn off LEDs one by one.

delay(200); // delay

}

for (int i = BASE; i < BASE + NUM; i ++)

{

digitalWrite(i, HIGH); // set I/O pins as “high”, turn on LEDs one by one

delay(200); // delay

}

}

Result You can see the LEDs blink by sequence.

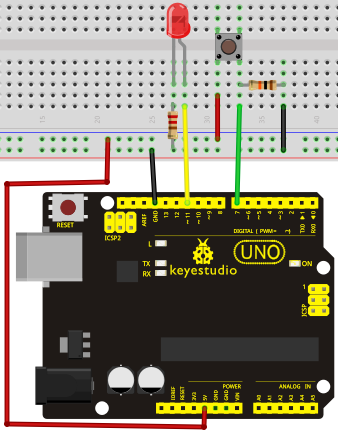

Project 6: Button-controlled LED

Introduction

I/O port means interface for INPUT and OUTPUT. Up until now, we have only used its OUTPUT function. In this experiment, we will try to use the input function, which is to read the output value of device connecting to it. We use 1 button and 1 LED using both input and output to give you a better understanding of the I/O function. Button switches, familiar to most of us, are a switch value (digital value) component. When it's pressed, the circuit is in closed (conducting) state.

Hardware required

Button switch*1

Red M5 LED*1

220Ω resistor*1

10KΩ resistor*1

Breadboard*1

Breadboard jumper wires

Circuit connection

Sample program

Now, let's begin the compiling. When the button is pressed, the LED will be on. After the previous study, the coding should be easy for you. In this program, we add a statement of judgment. Here, we use an if () statement. Arduino IDE is based on C language, so statements of C language such as while, switch etc. can certainly be used for Arduino program. When we press the button, pin 7 will output high level. We can program pin 11 to output high level and turn on the LED. When pin 7 outputs low level, pin 11 also outputs low level and the LED remains off.

int ledpin=11;// initialize pin 11

int inpin=7;// initialize pin 7

int val;// define val

void setup()

{

pinMode(ledpin,OUTPUT);// set LED pin as “output”

pinMode(inpin,INPUT);// set button pin as “input”

}

void loop()

{

val=digitalRead(inpin);// read the level value of pin 7 and assign if to val

if(val==LOW)// check if the button is pressed, if yes, turn on the LED

{ digitalWrite(ledpin,LOW);}

else

{ digitalWrite(ledpin,HIGH);}

}

Result

When the button is pressed, LED is on, otherwise, LED remains off. After the above process, the button controlled LED experiment is completed. The simple principle of this experiment is widely used in a variety of circuit and electric appliances. You can easily come across it in your every day life. One typical example is when you press a certain key of your phone, the backlight will be on.

Project 7: Responder experiment

Introduction

After completing all the previous experiments, we believe you will find this one easy. In this program, we have 3 buttons and a reset button controlling the corresponding 3 LEDs, using 7 digital I/O pins.

Hardware required

Button switch*4

Red M5 LED*1

Yellow M5 LED*1

Green M5 LED*1

220Ω resistor*3

10KΩ resistor*4

Breadboard*1

Breadboard jumper wires

Circuit connection

Sample program

int redled=8; // set red LED as “output”

int yellowled=7; // set yellow LED as “output”

int greenled=6; // set green LED as “output”

int redpin=5; // initialize pin for red button

int yellowpin=4; // initialize pin for yellow button

int greenpin=3; // initialize pin for green button

int restpin=2; // initialize pin for reset button

int red;

int yellow;

int green;

void setup()

{

pinMode(redled,OUTPUT);

pinMode(yellowled,OUTPUT);

pinMode(greenled,OUTPUT);

pinMode(redpin,INPUT);

pinMode(yellowpin,INPUT);

pinMode(greenpin,INPUT);

}

void loop() // repeatedly read pins for buttons

{

red=digitalRead(redpin);

yellow=digitalRead(yellowpin);

green=digitalRead(greenpin);

if(red==LOW)RED_YES();

if(yellow==LOW)YELLOW_YES();

if(green==LOW)GREEN_YES();

}

void RED_YES()// execute the code until red light is on; end cycle when reset button is pressed

{

while(digitalRead(restpin)==1)

{

digitalWrite(redled,HIGH);

digitalWrite(greenled,LOW);

digitalWrite(yellowled,LOW);

}

clear_led();

}

void YELLOW_YES()// execute the code until yellow light is on; end cycle when reset button is pressed

{

while(digitalRead(restpin)==1)

{

digitalWrite(redled,LOW);

digitalWrite(greenled,LOW);

digitalWrite(yellowled,HIGH);

}

clear_led();

}

void GREEN_YES()// execute the code until green light is on; end cycle when reset button is pressed

{

while(digitalRead(restpin)==1)

{

digitalWrite(redled,LOW);

digitalWrite(greenled,HIGH);

digitalWrite(yellowled,LOW);

}

clear_led();

}

void clear_led()// all LED off

{

digitalWrite(redled,LOW);

digitalWrite(greenled,LOW);

digitalWrite(yellowled,LOW);

}

Result

Whichever button is pressed first, the corresponding LED will be on! Then press the REST button to reset. After the above process, we have built our own simple responder.

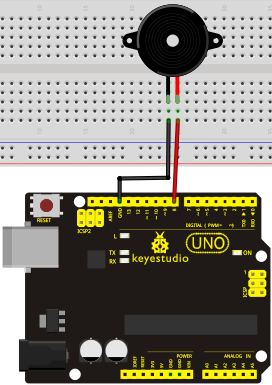

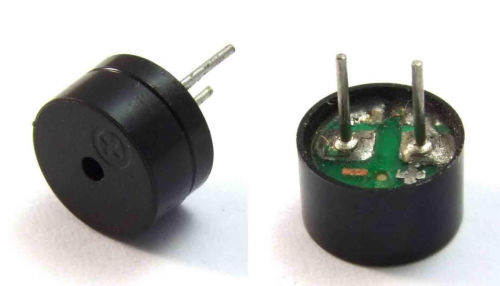

Project 8: Active buzzer

Introduction

Arduino enables us to make many interesting interactive projects, many of which we have done consists of a LED. They are light-related. While this time, the circuit will produce sound. The sound experiment is usually done with a buzzer or a speaker, while buzzer is simpler and easier to use. The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequencies produce different sounds. We can use Arduino to code the melody of a song, which is actually fun and simple.

Hardware required

Buzzer*1

Key *1

Breadboard*1

Breadboard jumper wires

Circuit connection

When connecting the circuit, pay attention to the positive & the negative poles of the buzzer. In the photo, you can see there are red and black lines. When the circuit is finished, you can begin programming.

Sample program

Program is simple. You control the buzzer by outputting high/low level.

int buzzer=8;// initialize digital IO pin that controls the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set pin mode as “output”

}

void loop()

{

digitalWrite(buzzer, HIGH); // produce sound

}

Result

After downloading the program, the buzzer experiment is completed. You can see the buzzer is ringing.

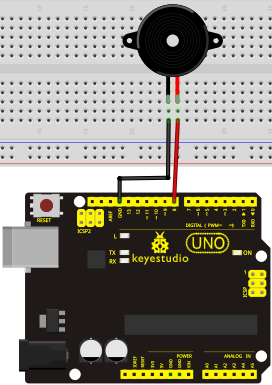

Project 9: Passive buzzer

Introduction

We can use Arduino to make many interactive works of which the most commonly used is acoustic-optic display. All the previous experiment has something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer or a speaker while buzzer is simpler and easier to use. The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequencies produce different sounds. We can use Arduino to code the melody of a song, which is actually quite fun and simple.

Hardware required

Passive buzzer*1

Key *1

Breadboard*1

Breadboard jumper wires

Sample program

int buzzer=8;// select digital IO pin for the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output

}

void loop()

{ unsigned char i,j;//define variable

while(1)

{ for(i=0;i<80;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(1);//delay1ms

digitalWrite(buzzer,LOW);//not sound

delay(1);//ms delay

}

for(i=0;i<100;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

digitalWrite(buzzer,LOW);//not sound

delay(2);//2ms delay

}

}

}

After downloading the program, buzzer experiment is finished.

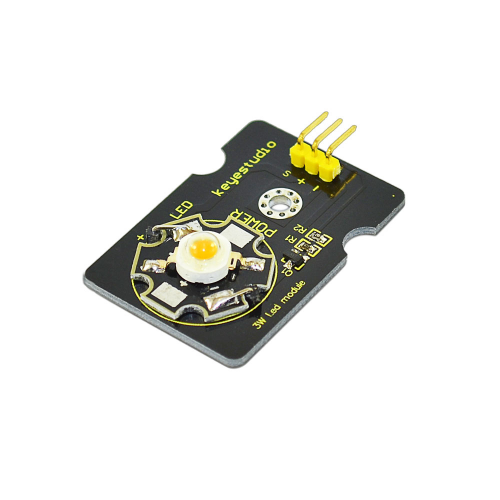

Project 10: 3W LED Module

Introduction

This LED module is of high brightness because the lamp beads it carries is 3w. We can apply this module to Arduino projects. For example, intelligent robots can use this module for illumination purpose.

Please note that the LED light can't be exposed directly to human eyes for safety concerns.

Specification

Color temperature: 6000~7000K

Luminous flux: 180~210lm

Current: 700~750mA

Power: 3W

Light angle: 140 degree

Working temperature: -50~80'C

Storage temperature: -50~100'C

High power LED module, controlled by IO port microcontroller

Great for Robot and search & rescue platform application

IO Type: Digital

Supply Voltage: 3.3V to 5V

Size: 40x28mm

Weight: 6g

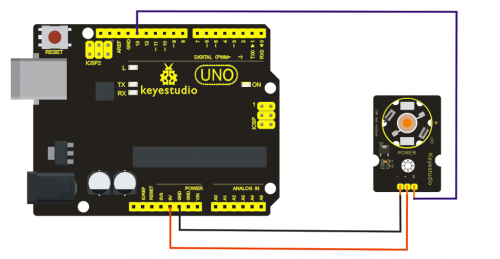

Connection Diagram

Sample Code

// the setup function runs once when you press reset or power the board

void setup() {

// initialize digital pin 13 as an output.

pinMode(13, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(13, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(13, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}

Project 11: Digital Push Button

Introduction

This is a basic application module. You can simply plug it into an IO shield to have your first taste of Arduino.

Advantages

Wide voltage range from 3.3V to 5V

Standard assembling structure (two 3mm diameter holes with multiple of 5mm as distance from center)

Easily recognizable interfaces of sensors ("A" for analog and "D" for digital)

Icons illustrate sensor function clearly

High quality connector

Immersion gold surface

Specification

Supply Voltage: 3.3V to 5V

Easy to 'plug and operate'

Large button keypad and high-quality first-class cap

Achieve interesting and interactive work

Interface: Digital

Size: 30*20mm

Weight: 4g

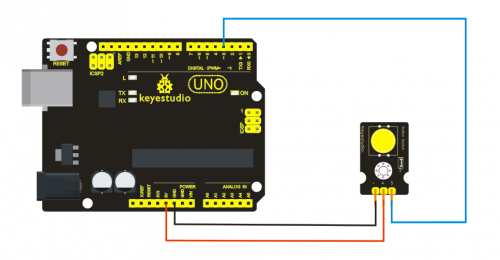

Connection diagram

Sample Code

/* # When you push the digital button, the Led 13 on the board will turn on. Otherwise,the led turns off.

*/

int ledPin = 13; // choose the pin for the LED

int inputPin = 3; // Connect sensor to input pin 3

void setup() {

pinMode(ledPin, OUTPUT); // declare LED as output

pinMode(inputPin, INPUT); // declare pushbutton as input

}

void loop(){

int val = digitalRead(inputPin); // read input value

if (val == HIGH) { // check if the input is HIGH

digitalWrite(ledPin, LOW); // turn LED OFF

} else {

digitalWrite(ledPin, HIGH); // turn LED ON

}

}

Project 12: Analog temperature sensor

Introduction

This module is based on the working principle of a thermistor (resistance varies with temperature change in the environment). It can sense temperature change in its surrounding and send the data to the analog IO in the Arduino board. All we need to do is to convert the sensor output data to degrees Celsius temperature by simple programming and display it. It's both convenient and effective, and it’s widely applied in gardening, home alarm system and other devices.

Specification

Interface type: analog

Working voltage: 5V

Temperature range: -55℃~315℃

Size: 30*20mm

Weight: 3g

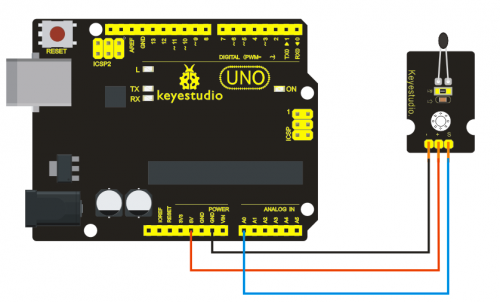

Connection Diagram

Sample Code

void setup()

{Serial.begin(9600);

}

// the loop routine runs over and over again forever:

void loop()

{int sensorValue = analogRead(A0);

Serial.println(sensorValue);

delay(1); }

We can see that the analog value is changing according to the temperature change in the environment. But it’s not very obvious. Let’s solve this by using the following equation. The value read from the serial port is similar to normal temperature, eg. The temperature right now is 30C.

#include <math.h>

double Thermister(int RawADC) {

double Temp;

Temp = log(((10240000/RawADC) - 10000));

Temp = 1 / (0.001129148 + (0.000234125 + (0.0000000876741 * Temp * Temp ))* Temp );

Temp = Temp - 273.15; // Convert Kelvin to Celcius

return Temp;

}

void setup()

{Serial.begin(9600);

} void loop() { Serial.print(Thermister(analogRead(0))); // display Fahrenheit Serial.println("c"); delay(500);

}

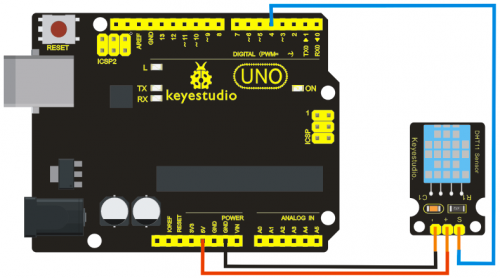

Project 13: DHT11 Temperature and Humidity Sensor

Introduction

This DHT11 Temperature and Humidity Sensor features calibrated digital signal output with the temperature and humidity sensor complex. Its technology ensures high reliability and excellent long-term stability. A high-performance 8-bit microcontroller is connected. This sensor includes a resistive element and a sense of wet NTC temperature measuring devices. It has excellent quality, fast response, anti-interference ability and high cost performance advantages. Each DHT11 sensor features extremely accurate calibration data of humidity calibration chamber. The calibration coefficients stored in the OTP program memory, internal sensors detect signals in the process, and we should call these calibration coefficients. The single-wire serial interface system is integrated to make it quick and easy. Qualities of small size, low power, and 20-meter signal transmission distance make it a wide applied application and even the most demanding one. Convenient connection, special packages can be provided according to users need.

Specification

Supply Voltage: +5 V

Temperature range: 0-50 °C error of ± 2 °C

Humidity: 20-90% RH ± 5% RH error

Interface: Digital

Size: 30*20mm

Weight: 4g

Connection diagram

Sample Code

Please download the DHT11Lib firstly.Or,see the website.

#include <dht11.h>

dht11 DHT;

#define DHT11_PIN 4

void setup(){

Serial.begin(9600);

Serial.println("DHT TEST PROGRAM ");

Serial.print("LIBRARY VERSION: ");

Serial.println(DHT11LIB_VERSION);

Serial.println();

Serial.println("Type,\tstatus,\tHumidity (%),\tTemperature (C)");

}

void loop(){

int chk;

Serial.print("DHT11, \t");

chk = DHT.read(DHT11_PIN); // READ DATA

switch (chk){

case DHTLIB_OK:

Serial.print("OK,\t");

break;

case DHTLIB_ERROR_CHECKSUM:

Serial.print("Checksum error,\t");

break;

case DHTLIB_ERROR_TIMEOUT:

Serial.print("Time out error,\t");

break;

default:

Serial.print("Unknown error,\t");

break;

}

// DISPLAT DATA

Serial.print(DHT.humidity,1);

Serial.print(",\t");

Serial.println(DHT.temperature,1);

delay(1000);

}

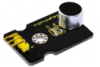

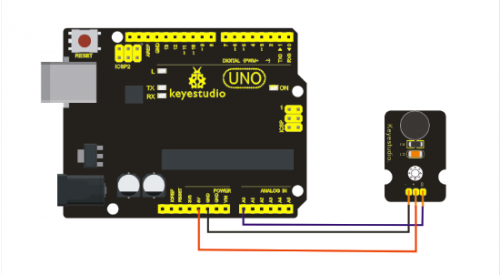

Project 14: Analog Sound Sensor

Introduction

Analog Sound Sensor is typically used in detecting the loudness in ambient environment. The Arduino can collect its output signal by imitating the input interface. You can use it to make some interesting interactive works such as a voice operated switch.

Specification

Supply Voltage: 3.3V to 5V

Detecting sound intensity

Interface: Analog

Size: 30*20mm

Weight: 4g

Connection Diagram

Sample Code

void setup()

{

Serial.begin(9600); // open serial port, set the baud rate at 9600 bps

}

void loop()

{

int val;

val=analogRead(0); //connect mic sensor to Analog 0

Serial.println(val,DEC);// print the sound value to serial monitor

delay(100);

}

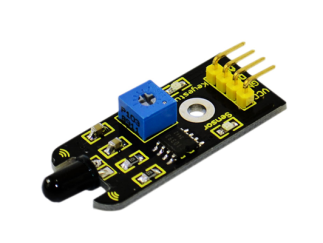

Project 15: Flame Sensor

Introduction

This flame sensor can be used to detect fire or other lights whose wavelength stands at 760 nm ~ 1100 nm. In the fire-fighting robot game, the flame plays an important role in the probe, which can be used as the robot's eyes to find fire source.

Specification

Supply Voltage: 3.3V to 5V

Detection range: 20cm (4.8V) ~ 100cm (1V)

Rang of Spectral Bandwidth: 760nm to 1100nm

Operating temperature: -25℃to 85℃

Interface: digital

Size: 44*16.7mm

Weight: 4g

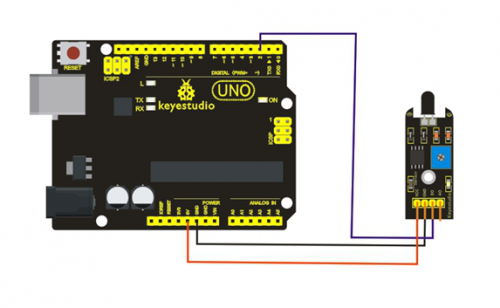

Connection Diagram

Sample Code

const int flamePin = 2; // the number of the flame pin

const int ledPin = 13; // the number of the LED pin

// variables will change:

int State = 0; // variable for reading status

void setup() {

// initialize the LED pin as an output:

pinMode(ledPin, OUTPUT);

// initialize the pushbutton pin as an input:

pinMode(flamePin, INPUT);

}

void loop(){

// read the state of the value:

State = digitalRead(flamePin);

if (State == HIGH) {

// turn LED on:

digitalWrite(ledPin, HIGH);

}

else {

// turn LED off:

digitalWrite(ledPin, LOW);

}

}

Project 16: Vibration Sensor

Introduction

What's the simplest way to check vibration with Arduino? Well, use a vibration sensor from keyestudio. You can directly plug it on our sensor Shield V5, vibrate this sensor, and Arduino can receive a digital signal, making it easy to make computation and programs in Arduino. Despite its simplicity, you can make full use of it with creative thinking, step counting, and crash warning light etc.

Specification

IO Type: Digital

Supply Voltage: 3.3V to 5V

Size: 40.7*16.7mm

Weight: 5g

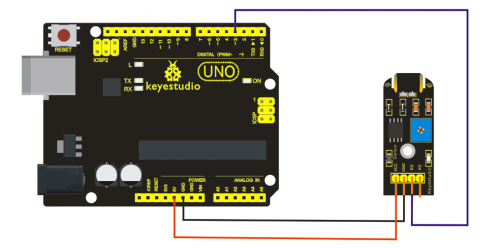

Connection Diagram

Sample Code

#define SensorLED 13

#define SensorINPUT 3 //Connect the sensor to digital Pin 3 which is Interrupts 1.

unsigned char state = 0;

void setup()

{

pinMode(SensorLED, OUTPUT);

pinMode(SensorINPUT, INPUT);

attachInterrupt(1, blink, FALLING);// Trigger the blink function when the falling edge is detected

}

void loop()

{ if(state!=0)

{

state = 0;

digitalWrite(SensorLED,HIGH);

delay(500);

}

else

digitalWrite(SensorLED,LOW);

}

void blink()//Interrupts function

{ state++;

}

Project 17: DS3231 Clock Module

Introduction

DS3231 is equipped with integrated TCXO and crystal, which makes it a cost-effective I2C real time clock with high precision. The device carries a battery input, so if you disconnect the main power supply, it can still maintain accurate timing. The integrated oscillator ensures the long-term accuracy of the device and reduces the number of components. DS3231 provides both commercial and industrial temperature range and supports 16 pins small-outline package (300mil). The module itself can adapt to the system of 3.3V and 5V without level switch, which is quite convenient!

Specification

Temperature range: -40 to +85; Timing accuracy : ± 5ppm (±0.432 seconds / day)

Provide battery backup for continuous timing

Low power consumption

Device package and function compatible with DS3231

Complete clock calendar function contains seconds and minutes, hour, week, date, month, and year timing and provides leap year compensation until 2100.

Two calendar clock

Output: 1Hz and 32.768kHz

Reset output and Input Debounce of Pushbutton

High speed (400kHz), I2C serial bus

Supply voltage: +3.3V to +5.5V

Digital temperature sensor with a precision of±3℃

Working temperature: -40 ~ C to +85 ~ C

16 pins Small Outline Package (300mil)

Certified by American Association of Underwriters Laboratories (UL)

Size: 30*20mm

Weight: 4g

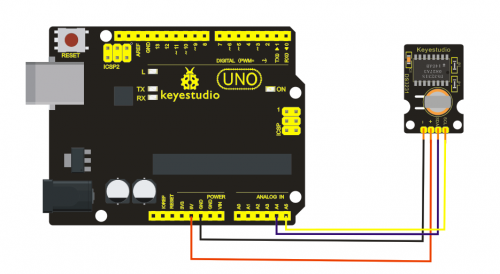

Connection Diagram

This module adopts the IIC test method, so we only need to connect ‘SDA’ to Arduino A4, ‘SCL’ to A5, ‘+’ to VCC and ‘-’ to GND as follows:

Sample Code

#include <Wire.h>

#include "DS3231.h"

DS3231 RTC; //Create the DS3231 object

char weekDay[][4] = {"Sun", "Mon", "Tue", "Wed", "Thu", "Fri", "Sat" };

//year, month, date, hour, min, sec and week-day(starts from 0 and goes to 6)

//writing any non-existent time-data may interfere with normal operation of the RTC.

//Take care of week-day also.

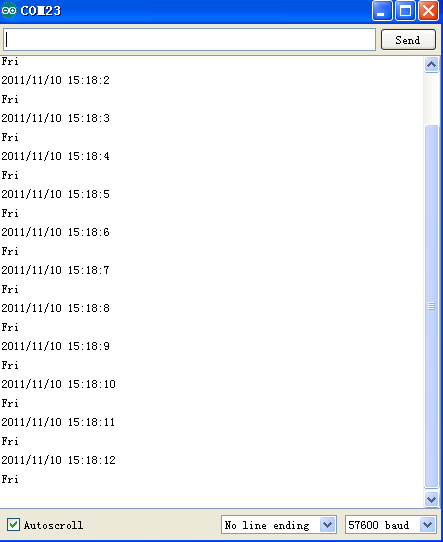

DateTime dt(2011, 11, 10, 15, 18, 0, 5);//open the series port and you can check time here or make a change to the time as needed.

void setup ()

{ Serial.begin(57600);//set baud rate to 57600

Wire.begin();

RTC.begin();

RTC.adjust(dt); //Adjust date-time as defined 'dt' above

}

void loop ()

{

DateTime now = RTC.now(); //get the current date-time

Serial.print(now.year(), DEC);

Serial.print('/');

Serial.print(now.month(), DEC);

Serial.print('/');

Serial.print(now.date(), DEC);

Serial.print(' ');

Serial.print(now.hour(), DEC);

Serial.print(':');

Serial.print(now.minute(), DEC);

Serial.print(':');

Serial.print(now.second(), DEC);

Serial.println();

Serial.print(weekDay[now.dayOfWeek()]);

Serial.println();

delay(1000);

}

Before compiling the code, you’d better put DS3231 library under file into Arduino catalogue,. When the above steps are done, you can upload the code to arduino and open the series monitor and get following results:

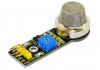

Project 18: keyestudio MQ135 Air Quality Sensor

Introduction

MQ135 adopts SnO2 as its gas sensitive material because SnO2 has low electrical conductivity in the clean air. So when surrounded by polluted air, the electrical conductivity of MQ135 will increase with the increase of pollutants, and the change in electrical conductivity can be converted to corresponding output signal.

MQ135 has a high sensitivity to Ammonia, sulfide, benzene vapor, smoke and other harmful gas. It can detect various harmful gases, making it a cost-effective choice suitable for multiple applications.

Specification

Product model: MQ135

Product type: Semiconductor gas sensor

Standard Package: Bakelite (Black Bakelite)

Target gas: Ammonia; methylbenzene; hydrogen

Standard circuit: Loop voltage Vc ≤24V DC

Heater voltage: VH 5.0V±0.2V AC or DC

Load resistance: Adjustable RL

Features of sensitive components under standard test condition: Heating resistor RH 31Ω±3Ω (room temperature)

Heater power consumption: PH ≤900mW

Surface resistance of sensitive material: Rs 2KΩ-20KΩ(in 100ppm NH3)

Sensitivity: S Rs(in air)/Rs(100ppmNH3)≥5

Concentration slope: α ≤0.6(R100ppm/R50ppm NH3)

Standard testing temperature/humidity : 20℃±2℃/65%±5%RH

Standard testing circuit: Vc:5.0V±0.1V

VH: 5.0V±0.1V

Preheating time: ≧48H

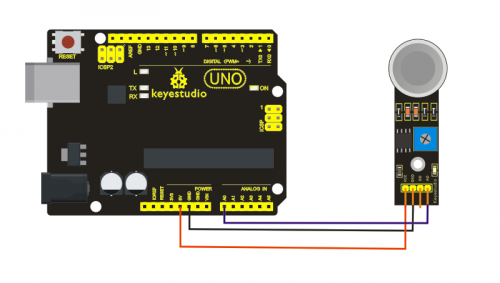

Connection diagram

Sample code

/*

AnalogReadSerial

Reads an analog input on pin 0, prints the result to the serial monitor

This example code is in the public domain.

*/

void setup() {

Serial.begin(9600);

}

void loop() {

int sensorValue = analogRead(A0);

Serial.println(sensorValue, DEC);

}

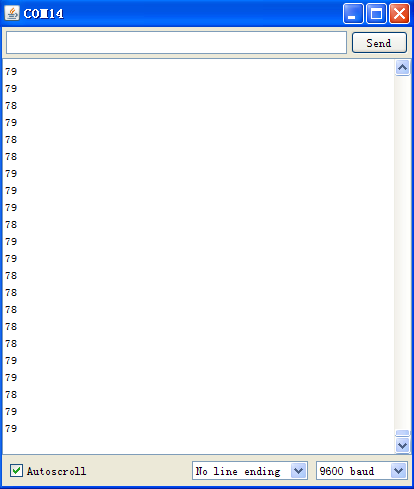

Turn on Serial monitor to check the pollution index of the air surrounds you:

Project 19: Color Sensor

Introduction

TCS3200 programmable color light-to-frequency converter applies to colorimeter measurement such as color printing, medical diagnosis, calibration of PC color monitor as well as process control and color coordination in oil paint, textile, cosmetics and printing material industries.

TCS3200 is built on the principle of three primary colors. Concretely speaking, TCS3200 allows only one specific primary color to go through and blocks other primary colors if a specific color filter was chosen. For example, when red filter was chosen, only red light can pass through while blue and green lights will be blocked out, so that we can get the intensity of red light. The strength of blue and green lights can be got in the same way. Finally, By analyzing the light strength of these three color, we can recognize the color reflected onto TCS3200.

Specification

Color Recognition Sensor Module

Condition: New

Chip: TCS230

Input voltage: DC 3 ~ 5V

Output frequency voltage: 0 ~ 5V

Use high brightness white LEDs

Can be connected directly to Microcontroller

Static detection of the measured object color

Best detection distance: 10mm

Color and more details are shown as pictures

PLS NOTE that due to lighting effects, difference in monitor's brightness/ contrast settings etc, there could be some slight differences in the color tone between the pictures and the actual item!

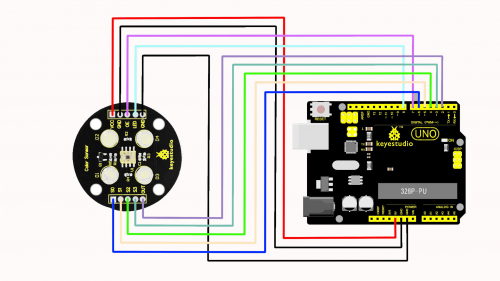

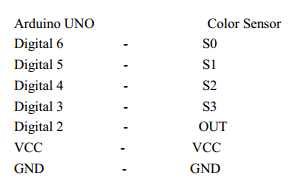

Connection diagram

There are in total 10 pins on this sensor and among them, these two pins, namely GND and LED, are directly connected to each other by Jumper Cap. The following is the correct connection between this color sensor and Arduino UNO:

Sample code

#include <TimerOne.h>

#define S0 6 // Please notice the Pin's define

#define S1 5

#define S2 4

#define S3 3

#define OUT 2

int g_count = 0; // count the frequecy

int g_array[3]; // store the RGB value

int g_flag = 0; // filter of RGB queue

float g_SF[3]; // save the RGB Scale factor

// Init TSC230 and setting Frequency.

void TSC_Init()

{

pinMode(S0, OUTPUT);

pinMode(S1, OUTPUT);

pinMode(S2, OUTPUT);

pinMode(S3, OUTPUT);

pinMode(OUT, INPUT);

digitalWrite(S0, LOW); // OUTPUT FREQUENCY SCALING 2%

digitalWrite(S1, HIGH);

}

// Select the filter color

void TSC_FilterColor(int Level01, int Level02)

{

if(Level01 != 0)

Level01 = HIGH;

if(Level02 != 0)

Level02 = HIGH;

digitalWrite(S2, Level01);

digitalWrite(S3, Level02);

}

void TSC_Count()

{

g_count ++ ;

}

void TSC_Callback()

{

switch(g_flag)

{

case 0:

Serial.println("->WB Start");

TSC_WB(LOW, LOW); //Filter without Red

break;

case 1:

Serial.print("->Frequency R=");

Serial.println(g_count);

g_array[0] = g_count;

TSC_WB(HIGH, HIGH); //Filter without Green

break;

case 2:

Serial.print("->Frequency G=");

Serial.println(g_count);

g_array[1] = g_count;

TSC_WB(LOW, HIGH); //Filter without Blue

break;

case 3:

Serial.print("->Frequency B=");

Serial.println(g_count);

Serial.println("->WB End");

g_array[2] = g_count;

TSC_WB(HIGH, LOW); //Clear(no filter)

break;

default:

g_count = 0;

break;

}

}

void TSC_WB(int Level0, int Level1) //White Balance

{

g_count = 0;

g_flag ++;

TSC_FilterColor(Level0, Level1);

Timer1.setPeriod(1000000); // set 1s period

}

void setup()

{

TSC_Init();

Serial.begin(9600);

Timer1.initialize(); // defaulte is 1s

Timer1.attachInterrupt(TSC_Callback);

attachInterrupt(0, TSC_Count, RISING);

delay(4000);

for(int i=0; i<3; i++)

Serial.println(g_array[i]);

g_SF[0] = 255.0/ g_array[0]; //R Scale factor

g_SF[1] = 255.0/ g_array[1] ; //G Scale factor

g_SF[2] = 255.0/ g_array[2] ; //B Scale factor

Serial.println(g_SF[0]);

Serial.println(g_SF[1]);

Serial.println(g_SF[2]);

}

void loop()

{

g_flag = 0;

for(int i=0; i<3; i++)

Serial.println(int(g_array[i] * g_SF[i]));

delay(4000);

}

Video

http://www.keyestudio.com/wp/2016/05/ks0180-keyestudio-sensor-kit-for-arduino-starters-k3/