KS0347 Keyestudio 130 Motor DC3-5V Driving Module: Difference between revisions

Keyestudio (talk | contribs) (Created blank page) |

Keyestudio (talk | contribs) No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''Description''' | |||

This pump driving module uses a single-channel H-bridge driver chip-HR1124S. | |||

The H-bridge driving part of HR1124S uses low on-resistance PMOS and NMOS power tubes, which can reduce chip’s power consumption and make the chip work safely for a longer time. In addition, HR1124S has low standby current and low quiescent operating current. | |||

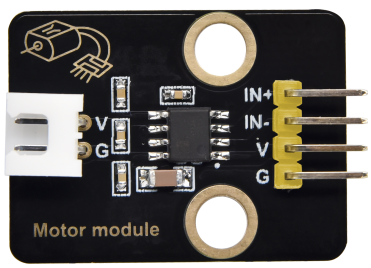

<br>[[Image:0347-1.png|500px|frameless]]<br> | |||

'''Parameters''' | |||

Control chip: HR1124S | |||

Rated voltage: 1.8V-6.8V | |||

Rated current: low standby current (0.01uA) and low quiescent working current (0.2mA), continuous output current 1.2A. | |||

Product size: 31.6mmx23.7mm | |||

Operating temperature range: 1°C ~ 50°C | |||

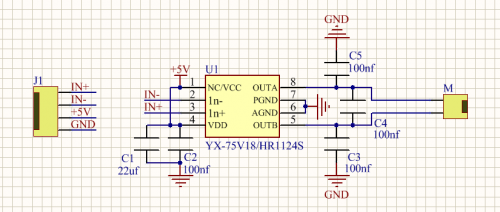

'''Schematic Diagram''' | |||

<br>[[Image:0347-2.png|500px|frameless]]<br> | |||

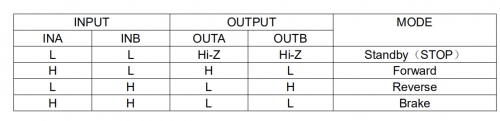

== Control Logic == | |||

Input and output logic table | |||

<br>[[Image:0347-3.png|500px|frameless]]<br> | |||

PWM can regulate the speed of the motor, for example, in clockwise, INA is high level and INB is low level, the rotation speed is the fastest. | |||

If INA inputs PWM wave, and INB also maintains low level; the duty cycle of INA is the speed regulation ratio. | |||

If INA keeps high levels and INB inputs PWM wave; the duty cycle of INB is the speed regulation ratio. | |||

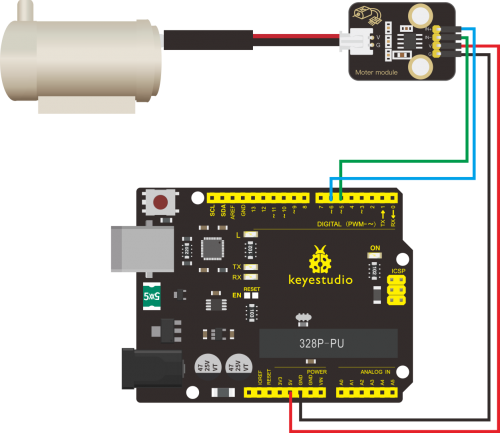

== Connection Diagram == | |||

<br>[[Image:0510-5.png|500px|frameless]]<br> | |||

<br>[[Image:0347-5.png|500px|frameless]]<br> | |||

== '''Test Code''' == | |||

6.1 Test Code 1:(high and low levels output control) | |||

<pre> | |||

//***************************************************************************** | |||

void setup(){ | |||

pinMode(5, OUTPUT);//Set digital 5 to Output | |||

pinMode(6, OUTPUT);//Set digital 6 to Output | |||

} | |||

void loop(){ | |||

//make the motor rotate clockwise for 3000ms | |||

digitalWrite(5,LOW);//set digital 5 to low level | |||

digitalWrite(6,HIGH);//set digital 5 to high level | |||

delay(3000);//delay in 3s | |||

//make motor stop rotating for 1000ms | |||

digitalWrite(5,LOW); | |||

digitalWrite(6,LOW); | |||

delay(1000); | |||

//make the motor rotate anticlockwise for 3000ms | |||

digitalWrite(5,HIGH); | |||

digitalWrite(6,LOW); | |||

delay(3000); | |||

//make motor stop rotating for 1000ms | |||

digitalWrite(5,LOW); | |||

digitalWrite(6,LOW); | |||

delay(1000); | |||

} | |||

//***************************************************************************** | |||

6.2 Test Code 2:(PWM output control) | |||

//***************************************************************************** | |||

void setup(){ | |||

pinMode(5, OUTPUT); //Set digital 5 to Output | |||

pinMode(6, OUTPUT); //set digital 6 to OUTPUT} | |||

void loop(){ | |||

//make the motor rotate clockwise for 3000ms | |||

analogWrite(5,0); //set PWM value at digital 5 to 0 | |||

analogWrite(6,200); //set PWM value at digital 6 to 200 | |||

delay(3000); //delay in 3s | |||

//make motor stop rotating for 1000ms | |||

analogWrite(5,0); | |||

analogWrite(6,0); | |||

delay(1000); | |||

//make the motor rotate anticlockwise for 3000ms | |||

analogWrite(5,200); | |||

analogWrite(6,0); | |||

delay(3000); | |||

//make the motor stop rotating for 1000ms | |||

analogWrite(5,0); | |||

analogWrite(6,0); | |||

delay(1000); | |||

} | |||

//***************************************************************************** | |||

</pre> | |||

== Test Result == | |||

Upload code, wire up and plug in the external power. The motor rotates for 3s clockwise, stops for 1s, anticlockwise for 3s and stops for 1s, circularly. | |||

Latest revision as of 11:08, 25 August 2021

Description

This pump driving module uses a single-channel H-bridge driver chip-HR1124S. The H-bridge driving part of HR1124S uses low on-resistance PMOS and NMOS power tubes, which can reduce chip’s power consumption and make the chip work safely for a longer time. In addition, HR1124S has low standby current and low quiescent operating current.

Parameters

Control chip: HR1124S Rated voltage: 1.8V-6.8V Rated current: low standby current (0.01uA) and low quiescent working current (0.2mA), continuous output current 1.2A. Product size: 31.6mmx23.7mm Operating temperature range: 1°C ~ 50°C

Schematic Diagram

Control Logic

Input and output logic table

PWM can regulate the speed of the motor, for example, in clockwise, INA is high level and INB is low level, the rotation speed is the fastest.

If INA inputs PWM wave, and INB also maintains low level; the duty cycle of INA is the speed regulation ratio.

If INA keeps high levels and INB inputs PWM wave; the duty cycle of INB is the speed regulation ratio.

Connection Diagram

Test Code

6.1 Test Code 1:(high and low levels output control)

//*****************************************************************************

void setup(){

pinMode(5, OUTPUT);//Set digital 5 to Output

pinMode(6, OUTPUT);//Set digital 6 to Output

}

void loop(){

//make the motor rotate clockwise for 3000ms

digitalWrite(5,LOW);//set digital 5 to low level

digitalWrite(6,HIGH);//set digital 5 to high level

delay(3000);//delay in 3s

//make motor stop rotating for 1000ms

digitalWrite(5,LOW);

digitalWrite(6,LOW);

delay(1000);

//make the motor rotate anticlockwise for 3000ms

digitalWrite(5,HIGH);

digitalWrite(6,LOW);

delay(3000);

//make motor stop rotating for 1000ms

digitalWrite(5,LOW);

digitalWrite(6,LOW);

delay(1000);

}

//*****************************************************************************

6.2 Test Code 2:(PWM output control)

//*****************************************************************************

void setup(){

pinMode(5, OUTPUT); //Set digital 5 to Output

pinMode(6, OUTPUT); //set digital 6 to OUTPUT}

void loop(){

//make the motor rotate clockwise for 3000ms

analogWrite(5,0); //set PWM value at digital 5 to 0

analogWrite(6,200); //set PWM value at digital 6 to 200

delay(3000); //delay in 3s

//make motor stop rotating for 1000ms

analogWrite(5,0);

analogWrite(6,0);

delay(1000);

//make the motor rotate anticlockwise for 3000ms

analogWrite(5,200);

analogWrite(6,0);

delay(3000);

//make the motor stop rotating for 1000ms

analogWrite(5,0);

analogWrite(6,0);

delay(1000);

}

//*****************************************************************************

Test Result

Upload code, wire up and plug in the external power. The motor rotates for 3s clockwise, stops for 1s, anticlockwise for 3s and stops for 1s, circularly.