KS0379 Keyestudio 3D Printer DRV8825 Kit (5PCS): Difference between revisions

Keyestudio (talk | contribs) |

Keyestudio (talk | contribs) |

||

| Line 23: | Line 23: | ||

==Connection Diagram== | ==Connection Diagram== | ||

It needs to connect DC 8-15V between motor power VMOT and GND. | It needs to connect DC 8-15V between motor power VMOT and GND. | ||

<br>[[ | <br>[[File:0379.png|700px|frameless]]<br> | ||

<br> | <br> | ||

==Sample Code== | ==Sample Code== | ||

<pre> | <pre> | ||

Revision as of 10:58, 11 June 2019

Introduction

This stepper motor driver is powered by DRV8825. This driver has a same pin and interface as our A4988 stepper motor driver, so it can replace the A4988 driver. It is a high-powered stepper motor driver.

DRV8825 has adjustable current limits, over-current and over-heat protection, six micro resolution (down 1/32-step).

It uses 8.2-45V and can provide up to approximately 1.5 per phase without heat sink or forced air flow (rated up to 2.2 with adequate additional cooling per coil)

Specifications

1. With only simple step and direction control interface;

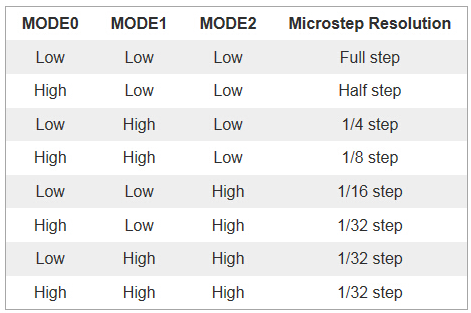

2. Six different step modes: full, half, 1/4, 1/8, 1/16, and 1/32;

3. Adjustable potentiometer can adjust the maximum current output, resulting in a higher step rate;

4. Automatic current decay mode detection / selection;

5. Overheat shutdown circuit, under voltage lockout, cross current protection;

6. Ground short circuit protection and load short circuit protection.

Settings for working mode

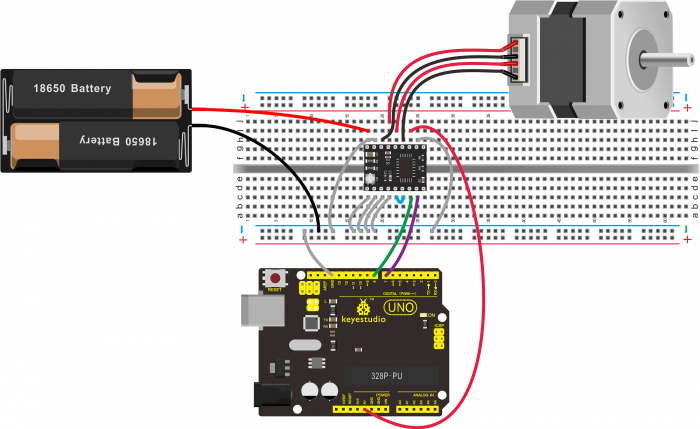

Connection Diagram

It needs to connect DC 8-15V between motor power VMOT and GND.

Sample Code

int dirPin = 7;

int stepperPin = 8;

void setup() {

pinMode(dirPin, OUTPUT);

pinMode(stepperPin, OUTPUT);

}

void step(boolean dir,int steps){

digitalWrite(dirPin,dir);

delay(50);

for(int i=0;i<steps;i++){

digitalWrite(stepperPin, HIGH);

delayMicroseconds(800);

digitalWrite(stepperPin, LOW);

delayMicroseconds(800);

}

}

void loop(){

step(true,1600);

delay(500);

step(false,1600*5);

delay(500);

}

Test Result

The selection end MS1, MS2, MS3 of three modes are all connected to GND, that is, full-step mode, and the motor needs 200 stepping values or a stepping 1.8° to turn a round. In the experiment, we first let the stepper motor reverse 8 circles and delay 0.5 seconds; then turn 40 circles and delay 0.5 seconds. If it is an half-step mode, then the number of both positive and reverse circle should be halved.

Package Included

- Keyestudio 3D Printer DRV8825 *5PCS

Resources Download

- Download the PDF:

https://drive.google.com/open?id=1PxEAtnFDJhnIAPZA_9GWJ1zJg3Q1Ae3C

Get One Now