Ks0071 keyestudio Mini Tank Robot: Difference between revisions

Keyestudio (talk | contribs) |

Keyestudio (talk | contribs) |

||

| (79 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

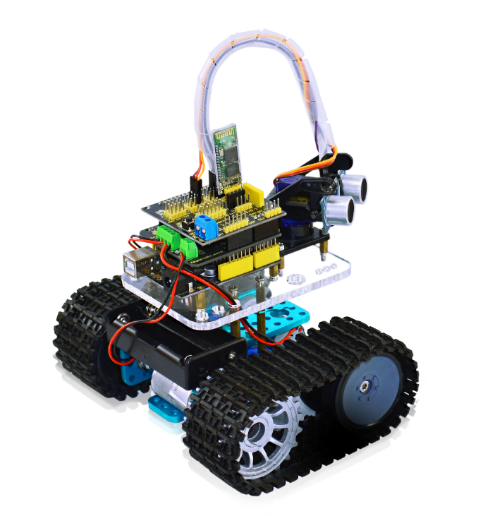

==keyestudio Mini Tank Robot== | |||

<br>[[File:711.png|500px|frameless|thumb]]<br> | |||

==Introduction== | |||

Mini tank robot is a learning application development system of microcontroller based on Arduino. | |||

It has functions such as ultrasonic obstacle avoidance, bluetooth remotecontrol. This kit contains many interesting programs. | |||

1. Motor parameters: 6V, 150rpm/ | It can also be expanded with external circuit modules to have further functions. This kit is designed to help you interestingly learn Arduino. | ||

You can learn Arduino MCU development ability while having fun. | |||

==Parameters== | |||

1. Motor parameters: 6V, 150rpm/min <br> | |||

2. Use L298P driver module for motor control.<br> | 2. Use L298P driver module for motor control.<br> | ||

3. Equipped with Ultrasonic module, can detect whether there are obstacles ahead, and the distance between the Tank robot and the obstacles to realize obstacle avoidance function.<br> | 3. Equipped with Ultrasonic module, can detect whether there are obstacles ahead, and the distance between the Tank robot and the obstacles to realize obstacle avoidance function.<br> | ||

| Line 13: | Line 16: | ||

5. Can be connected to external 7 ~ 12V power supply; with various sensor modules, it can realize various functions.<br> | 5. Can be connected to external 7 ~ 12V power supply; with various sensor modules, it can realize various functions.<br> | ||

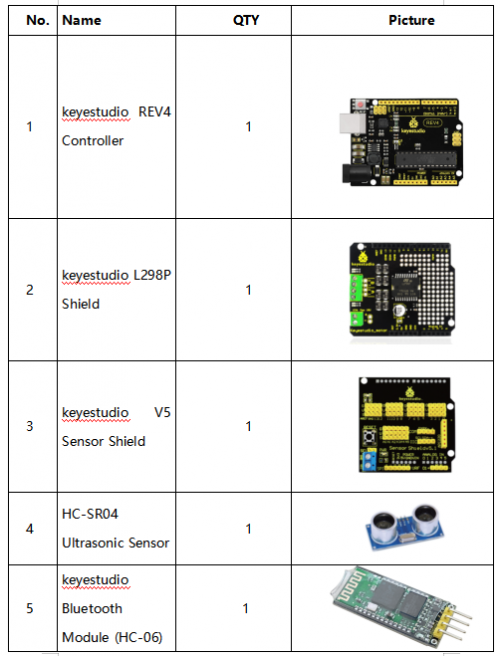

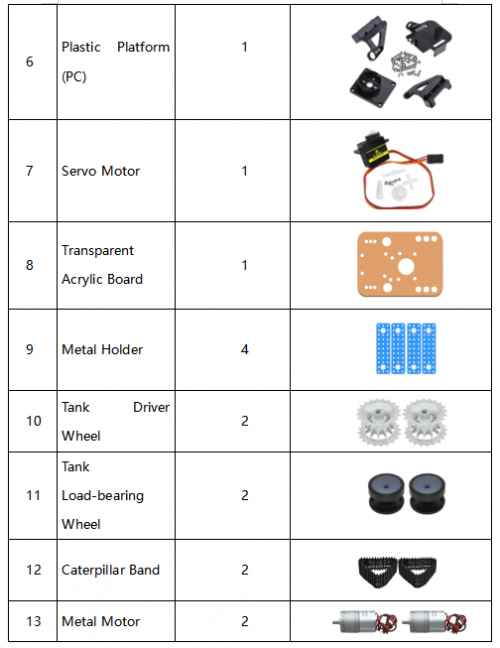

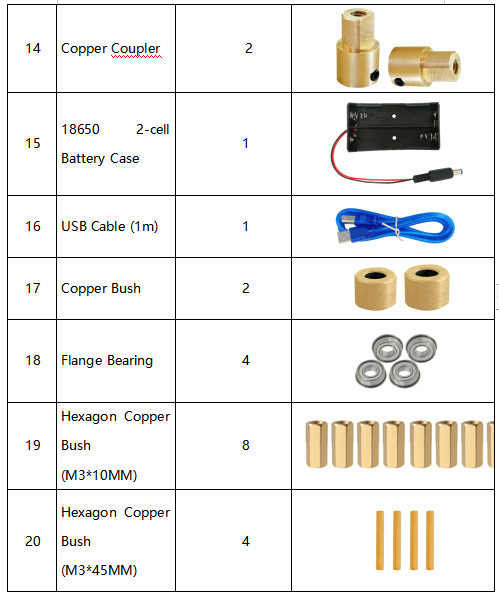

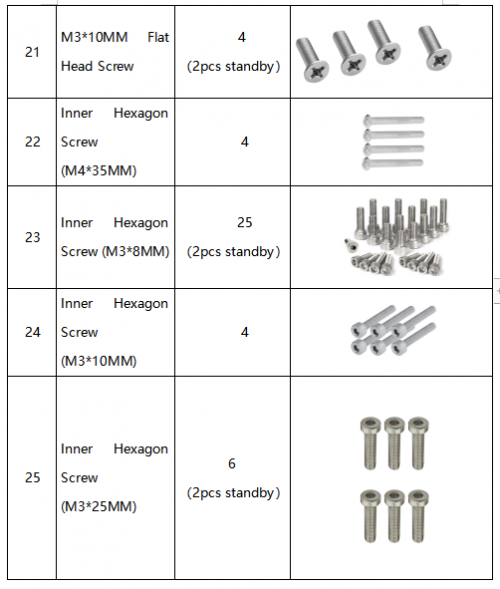

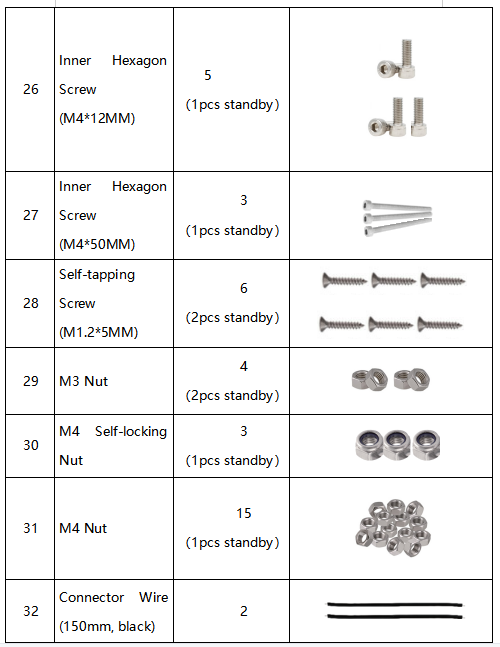

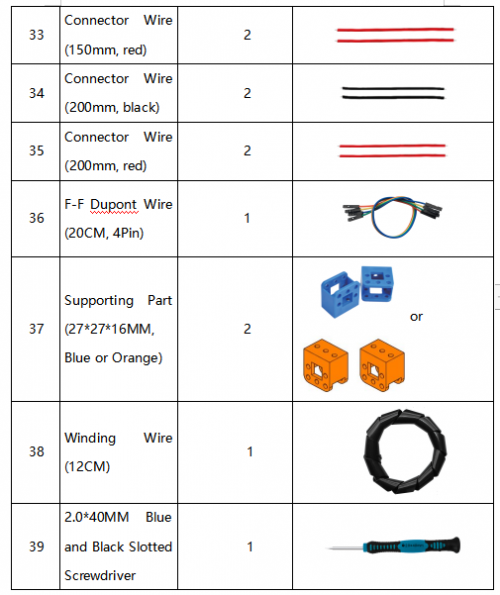

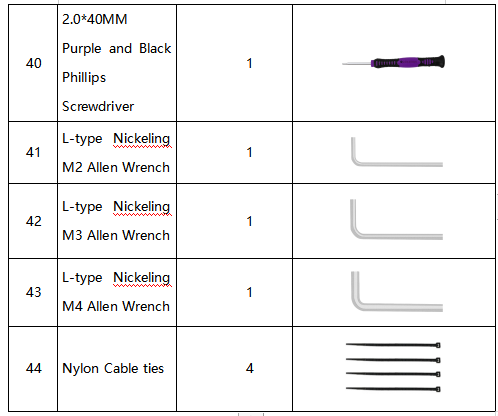

==Component List== | |||

<br>[[File:QQ图片20210903173440.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片20210903173441.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片20210903173.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片2021090317354.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片202109031735.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片20210903173516.png|500px|frameless|thumb]]<br> | |||

<br>[[File:QQ图片2021090317.png|500px|frameless|thumb]]<br> | |||

==Application of Arduino== | |||

<br>[[File: | <br>[[File:712.png|500px|frameless|thumb]]<br> | ||

== Introduction == | ===Introduction=== | ||

What’s Arduino?<br> | What’s Arduino?<br> | ||

Arduino is an open-source hardware project platform. This platform includes a circuit board with simple I/O function and program development environment software. It can be used to develop interactive products. For example, it can read signals of multiple switches and sensors, and control light, servo motor and other various physical devices. It’s widely applied in robot field. | |||

== Arduino installation and program upload == | ===Arduino installation and program upload:=== | ||

First, download the Arduino development software, click below hyperlink: <br> | First, download the Arduino development software, click below hyperlink:<br> | ||

arduino-1.5.6-r2-windows.rar<br> | [http://183.6.240.129/7326097.s21d-7.faiusrd.com/0/ABUIABAAGAAgx72stAUomOnzwAQ?f=arduino-1.5.6-r2-windows.rar&v=1451957958&wsiphost=local arduino-1.5.6-r2-windows.rar]<br> | ||

Downloaded file is a arduino-1.5.6-r2-windows.zip compressed folder, unzip it to your hard drive.<br> | Downloaded file is a arduino-1.5.6-r2-windows.zip compressed folder, unzip it to your hard drive.<br> | ||

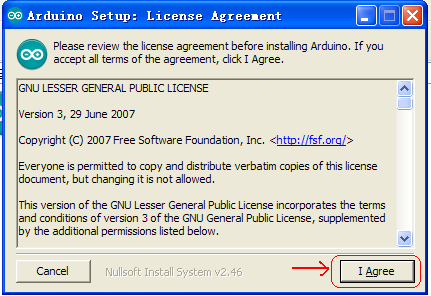

Double click Arduino-1.5.6 .exe. Click “I agree”; | Double click Arduino-1.5.6 .exe. Click “I agree”; | ||

<br>[[File: | |||

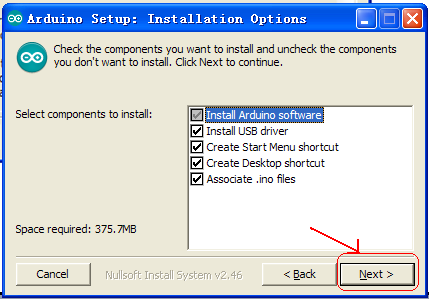

Click “Next”; | <br>[[File:713.png|500px|frameless|thumb]]<br> | ||

<br>[[File: | |||

Click “Next”; | |||

<br>[[File:714.png|500px|frameless|thumb]]<br> | |||

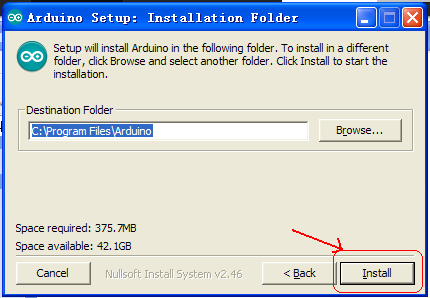

And then “Install”; | And then “Install”; | ||

Next, let’s install Arduino driver. <br> | <br>[[File:715.png|500px|frameless|thumb]]<br> | ||

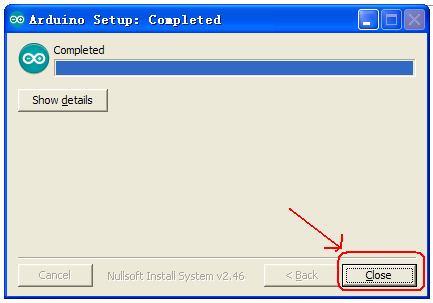

Wait for the installation to be completed, click close. | |||

<br>[[File:716.png|500px|frameless|thumb]]<br> | |||

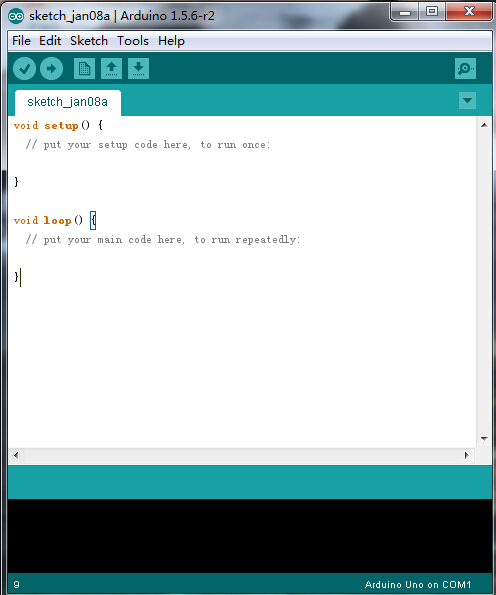

Below figure is what Arduino 1.5.6 looks like. | |||

<br>[[File:717.png|500px|frameless|thumb]]<br> | |||

'''Next, let’s install Arduino driver.''' <br> | |||

For different operating system, there may be slight difference in installation method. Below is an example in WIN 7.<br> | For different operating system, there may be slight difference in installation method. Below is an example in WIN 7.<br> | ||

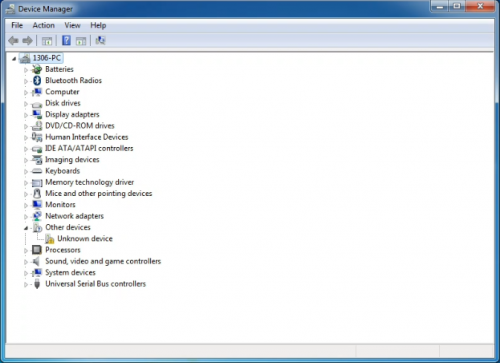

When you connect Arduino Uno to your computer the first time, right click “Computer” —> “Properties”—> “Device manager”, you can see “Unknown devices”. <br> | When you connect Arduino Uno to your computer at the first time, right click “Computer” —> “Properties”—> “Device manager”, you can see “Unknown devices”. <br> | ||

<br>[[File: | |||

<br>[[File:718.png|500px|frameless|thumb]]<br> | |||

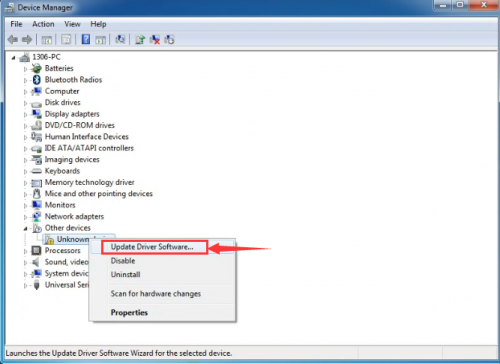

Click “Unknown devices”, select “Update Driver software”. | Click “Unknown devices”, select “Update Driver software”. | ||

<br>[[File: | |||

<br>[[File:719.png|500px|frameless|thumb]]<br> | |||

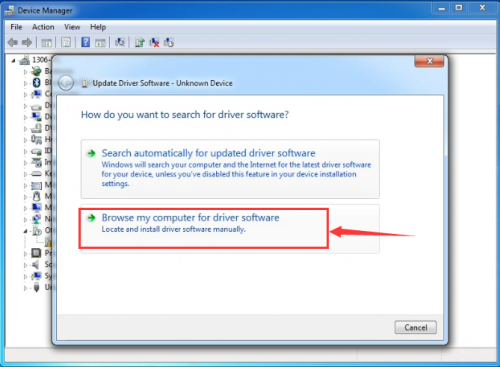

In this page, click “Browse my computer for driver software”. | In this page, click “Browse my computer for driver software”. | ||

<br>[[File: | |||

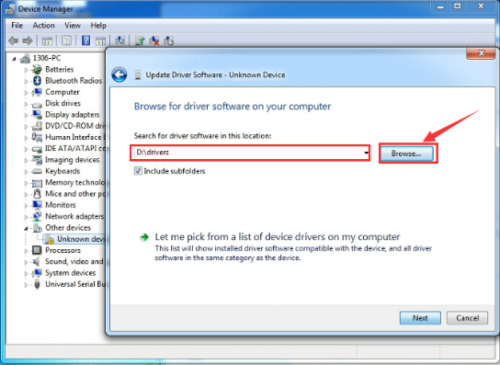

Find the “drivers” file. | <br>[[File:7110.png|500px|frameless|thumb]]<br> | ||

<br>[[File: | |||

Find the “drivers” file. | |||

<br>[[File:7111.png|500px|frameless|thumb]]<br> | |||

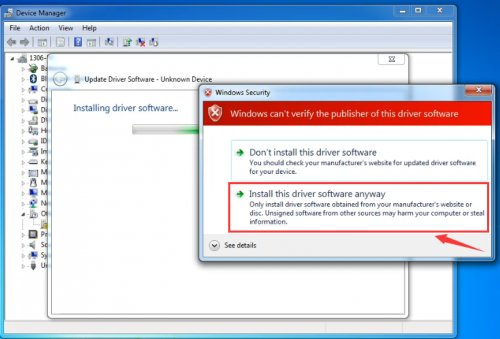

Click “Next”; select “Install this driver software anyway” to begin the installation. | Click “Next”; select “Install this driver software anyway” to begin the installation. | ||

After driver is installed, go to “Device manager” again. Right click “Computer” —> “Properties”—> “Device manager”, you can see UNO device as below figure shows, also the Com port info. | <br>[[File:7112.png|500px|frameless|thumb]]<br> | ||

<br>[[File: | |||

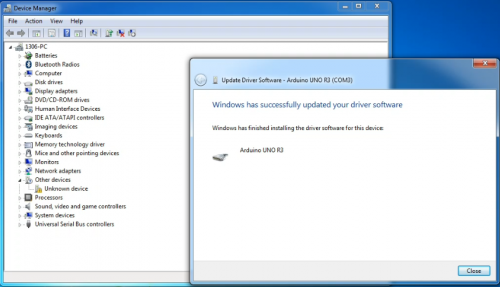

Installation completed; click “Close”. | |||

<br>[[File:7113.png|500px|frameless|thumb]]<br> | |||

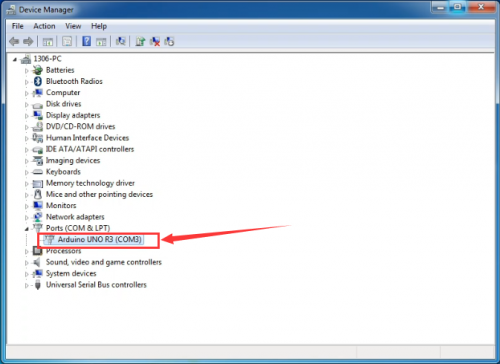

After driver is installed, go to “Device manager” again. Right click “Computer” —> “Properties”—> “Device manager”, you can see UNO device as below figure shows, also with the Com port info. | |||

<br>[[File:7114.png|500px|frameless|thumb]]<br> | |||

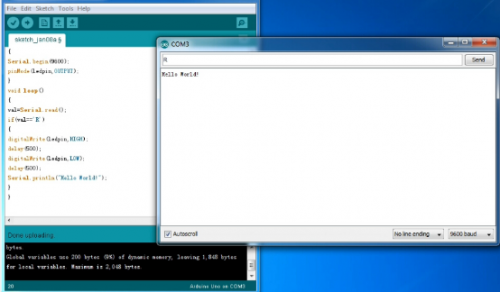

Following is a sketch uploading example called “Hello World!”. <br> | Following is a sketch uploading example called “Hello World!”. <br> | ||

First, open Arduino IDE. In this example sketch, we program Arduino to display “Hello World!” | First, open Arduino IDE. In this example sketch, we program Arduino to display “Hello World!” on serial monitor when it receives a specific character string “R”; also the on-board D13 LED will blink once each time it receives “R”.<br> | ||

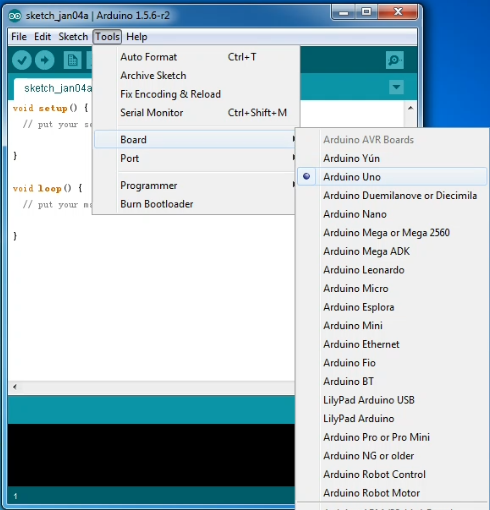

First, set up board; In “Tools”, select “Arduino Uno”. <br> | First, set up board; In “Tools”, select “Arduino Uno”. <br> | ||

<br>[[File: | |||

<br>[[File:7115.png|500px|frameless|thumb]]<br> | |||

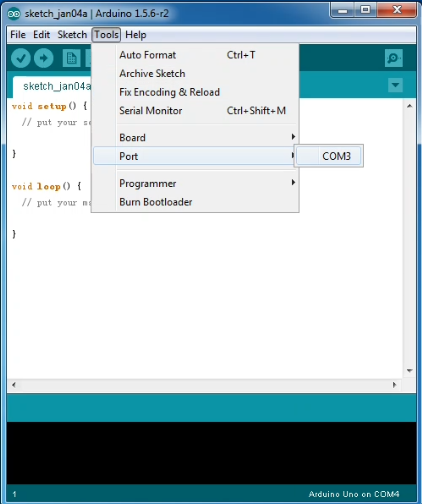

Next, set up COM port; In “Tools”, select “COM3”. | Next, set up COM port; In “Tools”, select “COM3”. | ||

<br>[[File: | |||

<br>[[File:7116.png|500px|frameless|thumb]]<br> | |||

After selection, you can see indicated area is the same with settings in “Device manager”. | After selection, you can see indicated area is the same with settings in “Device manager”. | ||

<br>[[File: | |||

Copy the example sketch and paste it to the IDE; click “Verify | <br>[[File:7117.png|500px|frameless|thumb]]<br> | ||

<br>[[File: | |||

After uploading is done, open “serial monitor | Copy the example sketch and paste it to the IDE; click “Verify [[File:7118.png|500px|frameless|thumb]]” to check compiling mistakes; click “Upload [[File:7119.png|500px|frameless|thumb]]” to upload the program to the board. | ||

<br>[[File: | |||

Congratulations! Your first sketch uploading is a | <br>[[File:7120.png|500px|frameless|thumb]]<br> | ||

After uploading is done, open “serial monitor[[File:7121.png|500px|frameless|thumb]] ”; enter “R”; click “Send”, the serial monitor will display “Hello World!” and the D13 LED will blink once. | |||

<br>[[File:7122.png|500px|frameless|thumb]]<br> | |||

Congratulations! Your first sketch uploading is successful! | |||

== Installation Method == | |||

1. Attach the supporting part to the metal holder with a inner hexagon screw. | |||

<br>[[Image:0071==1.png|800px|frameless]]<br> | |||

Then add a nut to fix the screw. | |||

<br>[[File:0071==2.png|800px|frameless]]<br> | |||

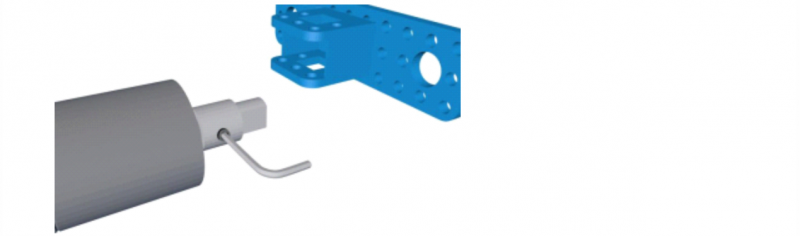

2.Plug a copper coupler into a metal motor; | |||

<br>[[Image:0071==3.png|800px|frameless]]<br> | |||

<br>[[Image:0071==4.png|800px|frameless]]<br> | |||

Then, reinforce them with a screwdriver. | |||

<br>[[Image:0071==5.png|800px|frameless]]<br> | |||

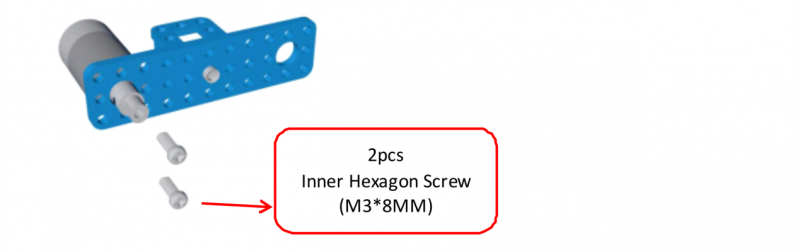

3.Fix the metal motor to the metal holder with two inner hexagon screws. | |||

<br>[[Image:0071==6.png|800px|frameless]]<br> | |||

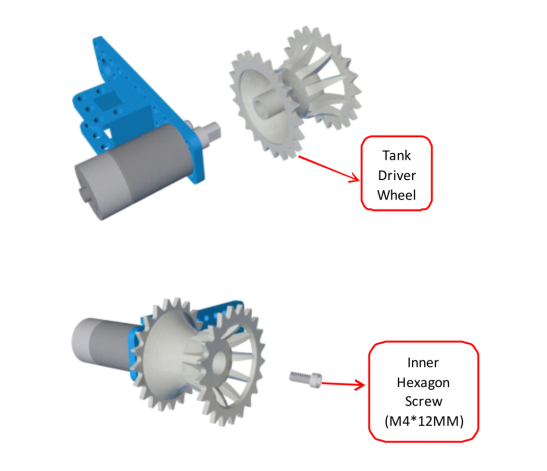

4. Plug a tank driver wheel into the metal motor and reinforce them with an inner hexagon screw. | |||

<br>[[Image:QQ图片20210906103449.png|800px|frameless]]<br> | |||

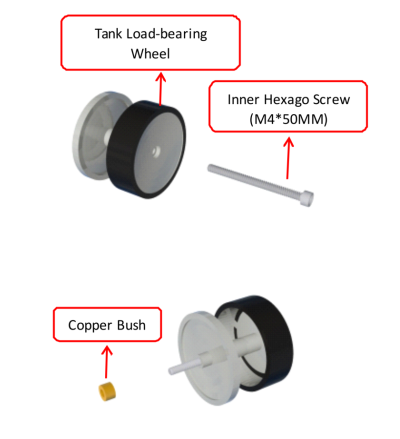

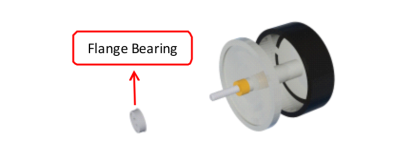

5. The tank load-bearing wheel is bolted to one screw and a copper bush. | |||

<br>[[Image:QQ图片20210906103554.png|800px|frameless]]<br> | |||

Then fix them with a flange bearing. | |||

<br>[[Image:QQ图片20210906103706.png|800px|frameless]]<br> | |||

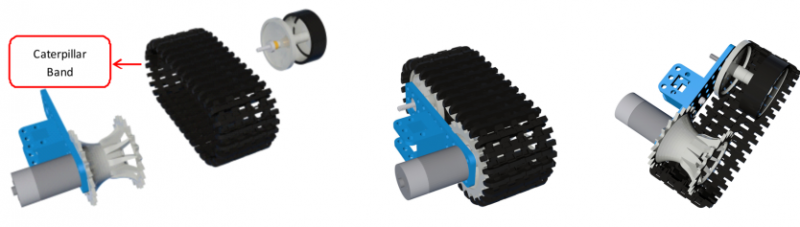

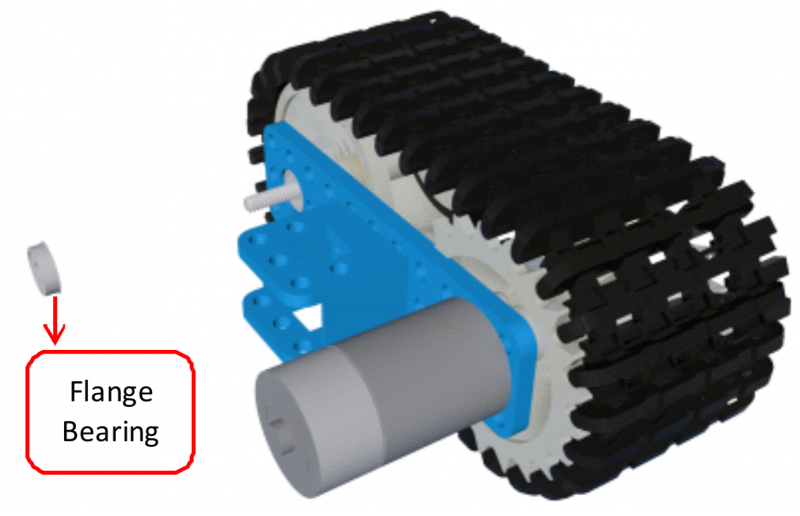

6.Put the tank driver wheel through a screw hole of the metal holder and the load-bearing wheel right into the caterpillar. | |||

<br>[[Image:QQ图片20210906103813.png|800px|frameless]]<br> | |||

Next screw a flange bearing to fix the metal holder and the wheel. | |||

<br>[[Image:QQ图片20210906103814.png|800px|frameless]]<br> | |||

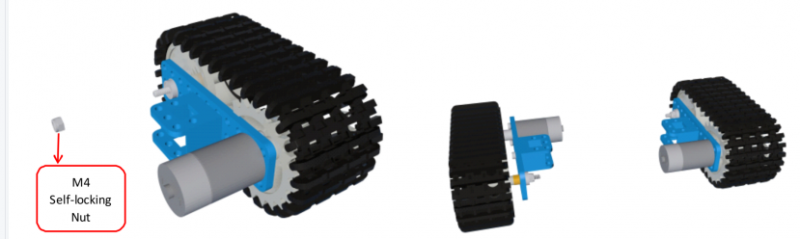

Then put a nut upon the flange bearing to reinforce. | |||

<br>[[Image:QQ图片20210906104635.png|800px|frameless]]<br> | |||

Finally combine the left part with the right part together. | |||

<br>[[Image:QQ图片20210906104636.png|800px|frameless]]<br> | |||

7.Attach the battery case to another metal holder with two flat head screws, using two nuts to fix them. | |||

<br>[[Image:0071==7.png|800px|frameless]]<br> | |||

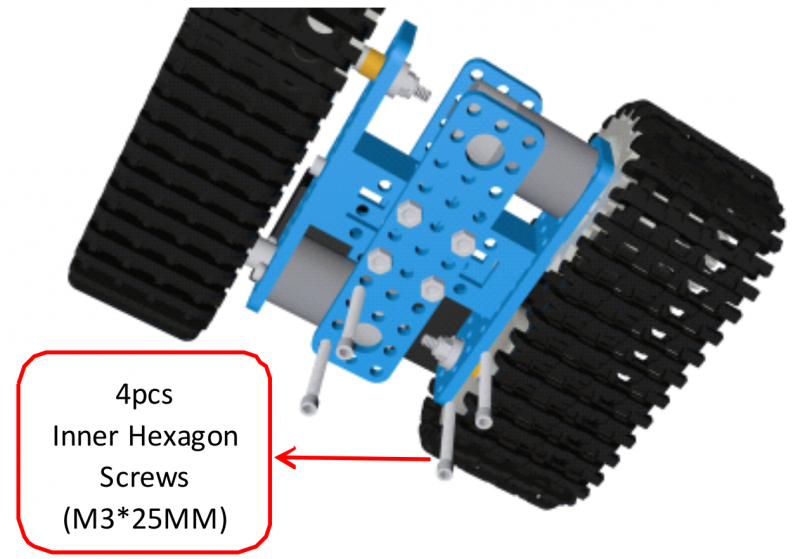

8. Fix four inner hexagon screws to the metal holder using 4 nuts. | |||

<br>[[Image:0071==18.png|800px|frameless]]<br> | |||

9. The battery is bolted to the supporting part with four nuts. | |||

<br>[[Image:0071==19.png|800px|frameless]]<br> | |||

10.Attach another metal holder to the four screws and then reinforce them with four nuts. | |||

<br>[[Image:0071==20.png|800px|frameless]]<br> | |||

11.Plug four inner hexagon screws through the supporting part. | |||

<br>[[Image:0071==21.png|800px|frameless]]<br> | |||

Then screw 4 copper bushes to the four hexagon screws. | |||

<br>[[Image:0071==22.png|800px|frameless]]<br> | |||

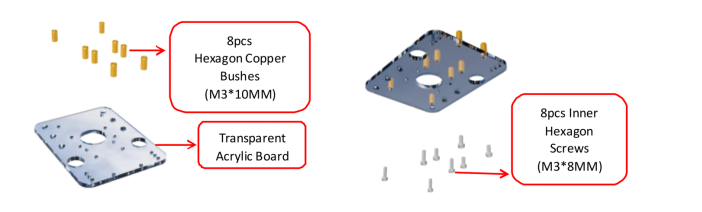

12.Screw 8 copper bushes upon a acrylic board using 8 inner hexagon screws. | |||

<br>[[Image:0071==8.png|800px|frameless]]<br> | |||

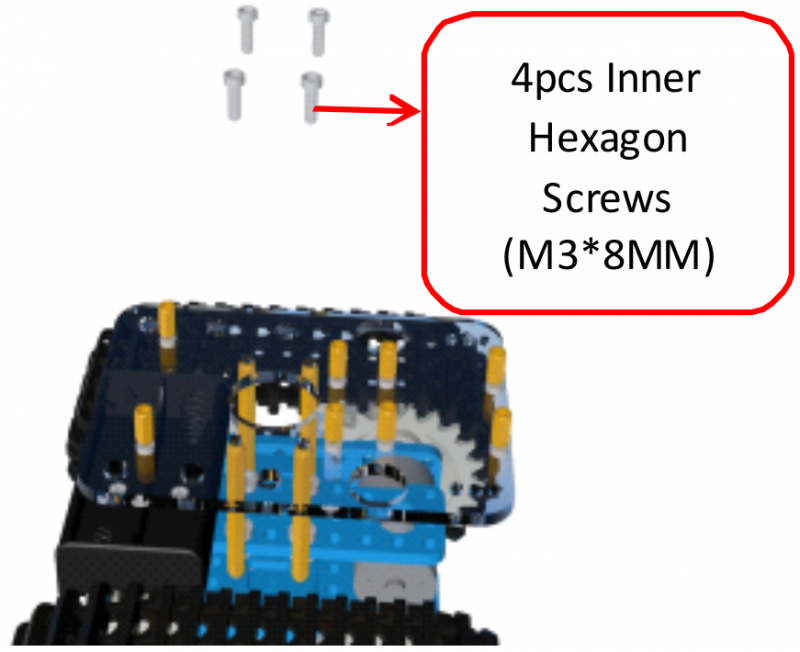

13.The acrylic board is bolted to the four copper bushes with 4 hexagon screws. | |||

<br>[[Image:0071==23.png|800px|frameless]]<br> | |||

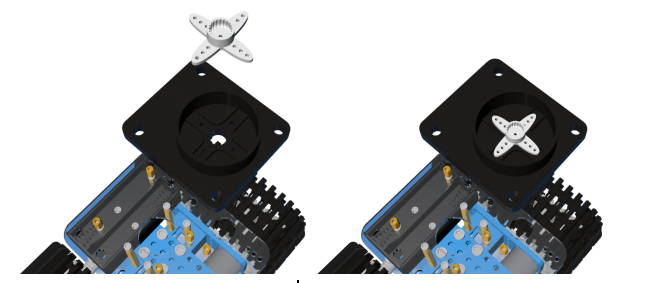

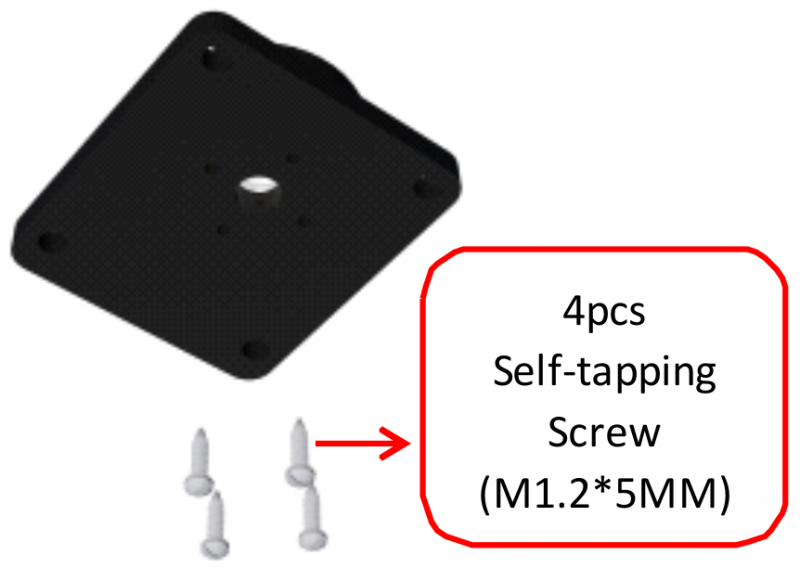

14. Cut the white cross to fit the size of the black cross and the attach the white one to the black one. | |||

<br>[[Image:0071==24.png|800px|frameless]]<br> | |||

Then fix the white cross with four tapping screws. | |||

<br>[[Image:0071==25.png|800px|frameless]]<br> | |||

15.Put the blue platform upon the cross, | |||

<br>[[Image:QQ图片20210906112138.png|800px|frameless]]<br> | |||

Then fix the platform using a tapping screw. | |||

<br>[[Image:0071==9.png|800px|frameless]]<br> | |||

16. Attach the two holder together, and then fix them with two tapping screws. | |||

<br>[[Image:0071==10.png|800px|frameless]]<br> | |||

<br>[[Image:0071==11.png|800px|frameless]]<br> | |||

17.The whole platform is bolted to four short copper bushes using four inner hexagon screws. | |||

<br>[[Image:0071==12.png|800px|frameless]]<br> | |||

18.Tie the ultrasonic sensor up with the black holder using two pieces of ribbon. | |||

<br>[[Image:0071==13.png|800px|frameless]]<br> | |||

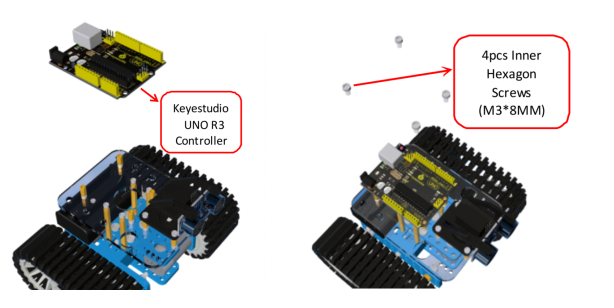

19.Attach the REV4 controller to the other four short copper bushes using four inner hexagon screws. | |||

<br>[[Image:0071==14.png|800px|frameless]]<br> | |||

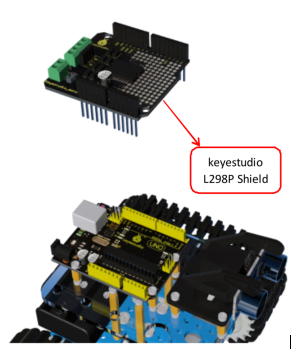

20. Plug the L298P shield into the controller; | |||

<br>[[Image:0071==15.png|800px|frameless]]<br> | |||

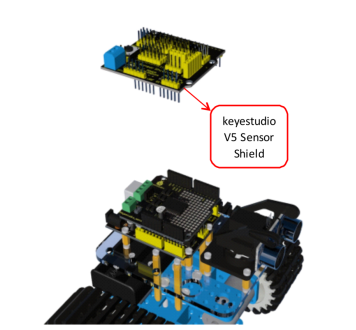

Next plug the V5 sensor shield into the L298P shield; | |||

<br>[[Image:0071==16.png|800px|frameless]]<br> | |||

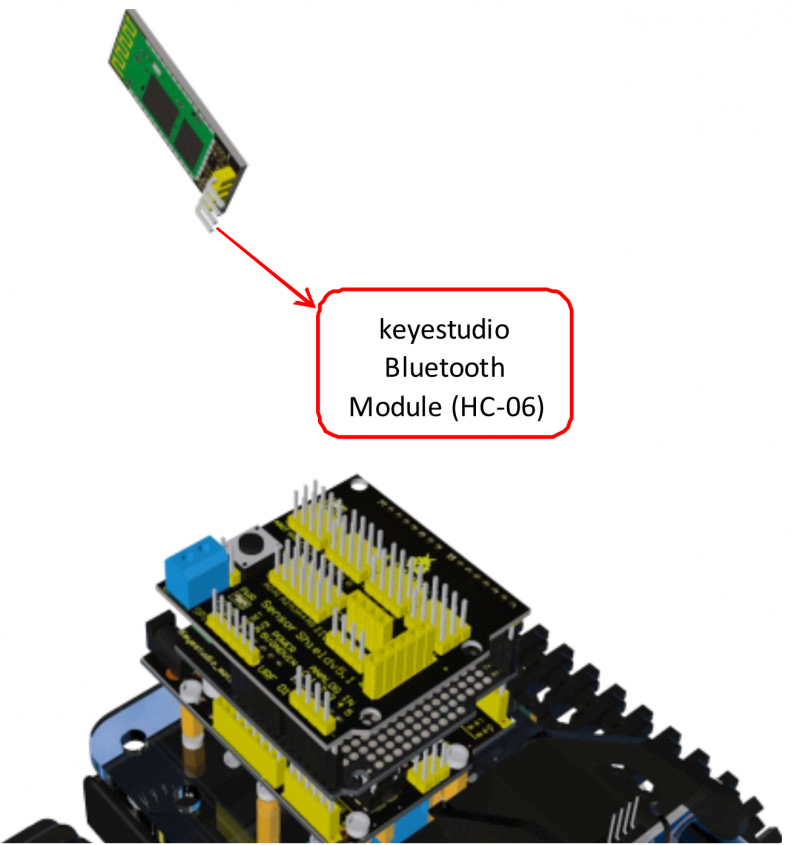

Finally plug the bluetooth into the serial ports on the V5 shield. | |||

<br>[[Image:0071==17.png|800px|frameless]]<br> | |||

==Project Details== | |||

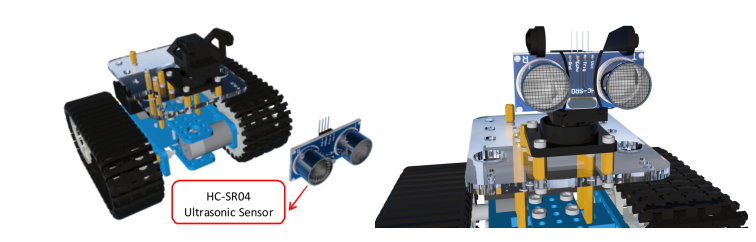

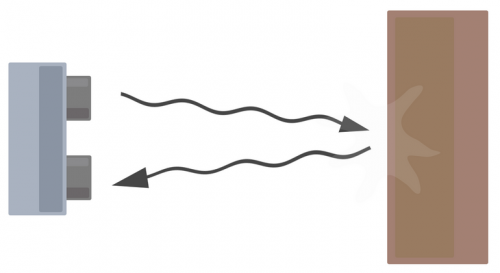

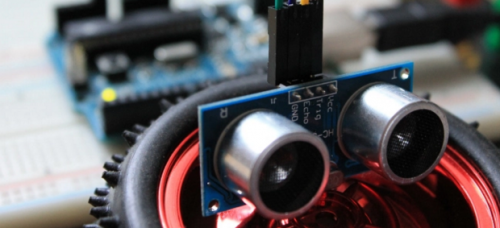

===Project 1: Ultrasonic Sensor=== | |||

<br>[[File:aa.png|500px|frameless|thumb]]<br> | |||

'''Introduction'''<br> | |||

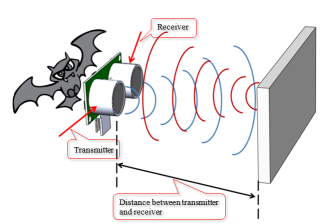

The HC-SR04 Ultrasonic Sensor is a very affordable proximity distance sensor that has been used mainly for object avoidance in various robotics projects. It essentially gives your Arduino eyes spacial awareness and can prevent your robot from crashing or falling off a table. It has also been used in turret applications, water level sensing, and even as a parking sensor. This simple project will use the HC-SR04 sensor with an Arduino and a Processing sketch to provide a neat little interactive display on your computer screen. | |||

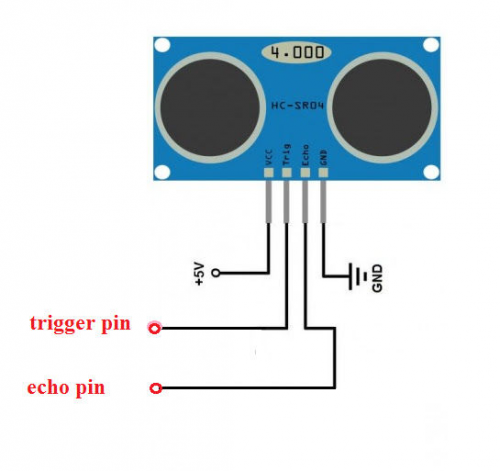

<br>[[File:bb.png|500px|frameless|thumb]]<br> | |||

'''Specification'''<br> | |||

Working Voltage: DC 5V<br> | |||

Working Current: 15mA<br> | |||

Working Frequency: 40Hz<br> | |||

Max Range: 4m<br> | |||

Min Range: 2cm<br> | |||

Measuring Angle: 15 degree<br> | |||

Trigger Input Signal: 10µS TTL pulse<br> | |||

Echo Output Signal Input TTL lever signal and the range in proportion <br> | |||

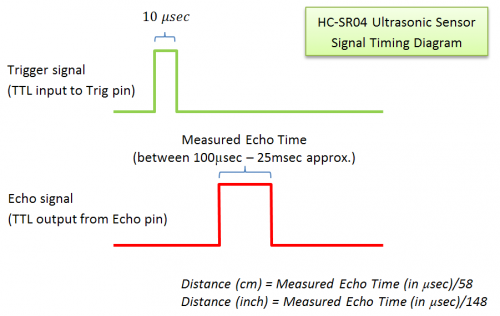

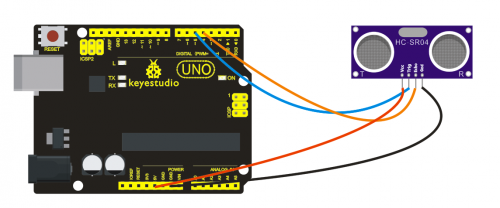

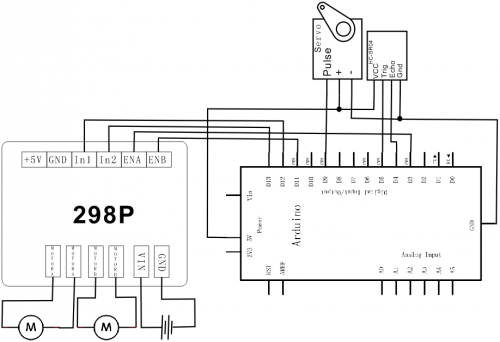

'''Connection Diagram'''<br> | |||

<br>[[File:cc.png|500px|frameless|thumb]]<br> | |||

<br>[[File:dd.png|500px|frameless|thumb]]<br> | |||

<br>[[File:ee.png|500px|frameless|thumb]]<br> | |||

'''Sample Code'''<br> | |||

Wiring Method:<br> | |||

VCC to Arduino 5v <br> | |||

GND to Arduino GND<br> | |||

Echo to Arduino pin 4<br> | |||

Trig to Arduino pin 5<br> | |||

<pre> | |||

#define echoPin 4 // Echo Pin | |||

#define trigPin 5 // Trigger Pin | |||

#define LEDPin 13 // Onboard LED | |||

int maximumRange = 200; // Maximum range needed | |||

int minimumRange = 0; // Minimum range needed | |||

long duration, distance; // Duration used to calculate distance | |||

void setup() { | |||

Serial.begin (9600); | |||

pinMode(trigPin, OUTPUT); | |||

pinMode(echoPin, INPUT); | |||

pinMode(LEDPin, OUTPUT); // Use LED indicator (if required) | |||

} | |||

void loop() { | |||

/* The following trigPin/echoPin cycle is used to determine the | |||

distance of the nearest object by bouncing soundwaves off of it. */ | |||

digitalWrite(trigPin, LOW); | |||

delayMicroseconds(2); | |||

digitalWrite(trigPin, HIGH); | |||

delayMicroseconds(10); | |||

digitalWrite(trigPin, LOW); | |||

duration = pulseIn(echoPin, HIGH); | |||

//Calculate the distance (in cm) based on the speed of sound. | |||

distance = duration/58.2; | |||

if (distance >= maximumRange || distance <= minimumRange){ | |||

/* Send a negative number to computer and Turn LED ON | |||

to indicate "out of range" */ | |||

Serial.println("-1"); | |||

digitalWrite(LEDPin, HIGH); | |||

} | |||

else { | |||

/* Send the distance to the computer using Serial protocol, and | |||

turn LED OFF to indicate successful reading. */ | |||

Serial.println(distance); | |||

digitalWrite(LEDPin, LOW); | |||

} | |||

//Delay 50ms before next reading. | |||

delay(50); | |||

} | |||

</pre> | |||

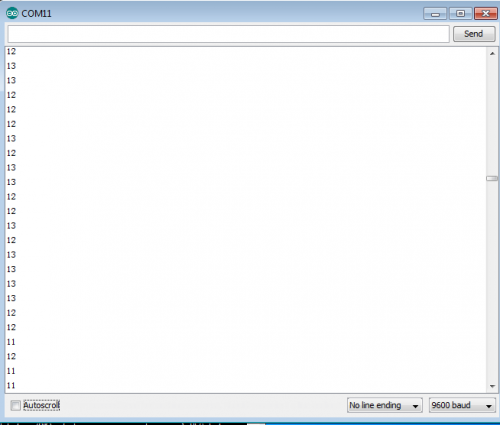

'''Result'''<br> | |||

After connection and uploading, when ultrasonic sensor senses obstacle within sensing area, it is measuring the distance between itself and obstacle and the value of distance is displayed on serial monitor as shown in below figure. | |||

<br>[[File:ff.png|500px|frameless|thumb]]<br> | |||

=== '''Project 2: Bluetooth Module'''=== | |||

[[File:ks0071 2-1.png|thumb]] | |||

'''Introduction'''<br> | |||

This Bluetooth module can easily achieve serial wireless data transmission. Its operating frequency is among the most popular 2.4GHz ISM frequency band (i.e. Industrial, scientific and medical). It adopts Bluetooth 2.1+EDR standard. In Bluetooth 2.1, signal transmit time of different devices stands at a 0.5 seconds interval so that the workload of bluetooth chip can be reduced substantially and more sleeping time can be saved for bluetooth. This module is set with serial interface, which is easy-to-use and simplifying overall design/development cycle.<br> | |||

'''Specification '''<br> | |||

Bluetooth Protocol: Bluetooth 2.1+ EDR standard<br> | |||

USB Protocol: USB v1.1/2.0<br> | |||

Operating Frequency: 2.4GHz ISM frequency band<br> | |||

Modulation Mode: Gauss frequency Shift Keying<br> | |||

Transmit Power: ≤ 4dBm, second stage<br> | |||

Sensitivity: ≤-84dBm at 0.1% Bit Error Rate<br> | |||

Transmission Speed: 2.1Mbps(Max)/160 kbps(Asynchronous); 1Mbps/1Mbps(Synchronous)<br> | |||

Safety Feature: Authentication and encryption<br> | |||

Supported Configuration: Bluetooth serial port (major and minor)<br> | |||

Supply Voltage: 5V DC 50mA<br> | |||

Operating Temperature: -20 to 55℃<br> | |||

<span style=color:red>Note: Before uploading test code, we can’t insert Bluetooth module, otherwise the program will fail to be uploaded. After uploading test code successfully, connect Bluetooth and Bluetooth module , pair and connect APP.</span> | |||

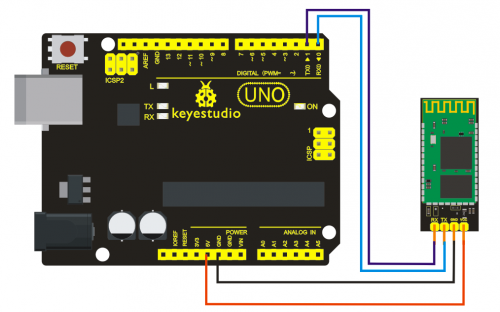

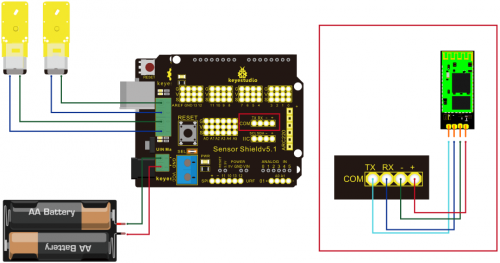

'''Connection Diagram'''<br> | |||

<br>[[File:gg.png|500px|frameless|thumb]]<br> | |||

'''Sample Code'''<br> | |||

<pre> | |||

int val; | |||

int ledpin=13; | |||

void setup() | |||

{ | |||

Serial.begin(9600); | |||

pinMode(ledpin,OUTPUT); | |||

} void loop() | |||

{ val=Serial.read(); | |||

if(val=='a') | |||

{ | |||

digitalWrite(ledpin,HIGH); | |||

delay(250); | |||

digitalWrite(ledpin,LOW); | |||

delay(250); | |||

Serial.println("keyestudio"); | |||

}} | |||

</pre> | |||

'''Result'''<br> | |||

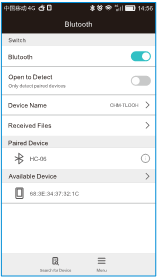

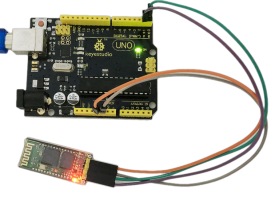

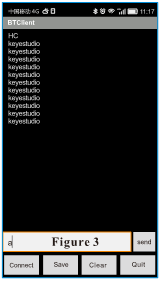

After powered up, power indicator D1 is on, and LED on Bluetooth module is blinking; open Bluetooth on mobile phone, pair them, input 1234, and finish pairing as shown in Figure 1 ; open APP—Bluetooth serial communication assistant, connect it to Bluetooth, select normal mode, complete connection, and LED on Bluetooth module is on as shown in Figure 2; input an “a” in the assistant, and display “keyesdudio” in it as shown in Figure 3. | |||

Figure 1 - - - - - - - - - - - - Figure 2 - - - - - - - - - - - - - Figure 3 | |||

<br>[[File:Ks0071 2-5.png|500px|frameless|thumb]] [[File:ii.png|500px|frameless|thumb]] [[File:Ks0071 2-6.png|500px|frameless|thumb]]<br> | |||

=== '''Project 3: Obstacle Avoidance Tank '''=== | |||

<br>[[File:71.png|500px|frameless|thumb]]<br> | |||

'''Introduction'''<br> | |||

This project is a simple obstacle avoidance tank robot system based on Arduino, including the software and hardware design. The controller part is a UNO board. Ultrasonic sensor and servo motors are used to detect whether there are obstacles ahead, and feedback the signal to UNO. UNO will analyze the signal to determine and control the motors movement to adjust Tank moving direction. Therefore the tank robot can automatically avoid obstacles. | |||

'''Working Principle'''<br> | |||

Ultrasonic ranging: the controller sends out a a high level signal of more than 10μs, when the output pin receives the high level signal, the timer will be on; when the signal changes to low level, we can read the time period of the timer, which is the time used for this ultrasonic wave transceiving. Together with its transmission speed, we can calculate the distance.<br> | |||

After we use the ultrasonic sensor to detect the distance from an obstacle, we can control the movement of the Tank according to the data.<br> | |||

If the distance from the obstacle is < 10cm, the Tank moves backward; if the distance is >=25cm, the Tank moves forward; if the distance is <25cm, we control the movement of the servo motors to measure the distance of the left and right. If both the distance are <10cm, the Tank moves backward; if the distance are both >= 10cm, and distance on the left is more than the distance on the right, the Tank moves to the left; if distance on the left is <= the distance on the right, the Tank moves to the right. <br> | |||

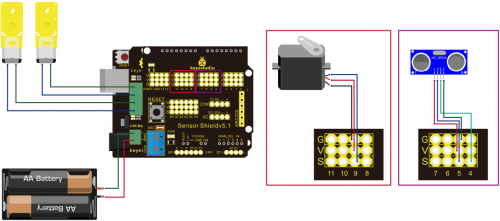

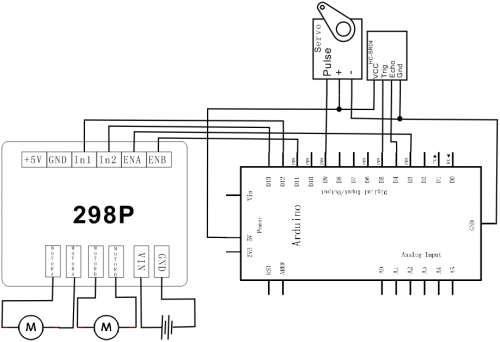

'''Schematic and Connection Diagram'''<br> | |||

<br>[[File:ks0071 1-2.png|500px|frameless|thumb]]<br> | |||

<br>[[File:72.png|500px|frameless|thumb]]<br> | |||

'''Sample Code'''<br> | |||

<pre> | |||

/* | |||

L = Left | |||

R = Right | |||

F = forward | |||

B = backward | |||

*/ | |||

#include <Servo.h> | |||

int pinLB = 12; // define pin 12 | |||

int pinLF = 3; // define pin 3 | |||

int pinRB = 13; // define pin 13 | |||

int pinRF = 11; // define pin 11 | |||

//////////////////////////////// | |||

int inputPin = 4; // define pin for sensor echo | |||

int outputPin =5; // define pin for sensor trig | |||

int Fspeedd = 0; // forward speed | |||

int Rspeedd = 0; // right speed | |||

int Lspeedd = 0; // left speed | |||

int directionn = 0; // forward=8 backward=2 left=4 right=6 | |||

Servo myservo; // set myservo | |||

int delay_time = 250; // settling time after steering servo motor moving B | |||

int Fgo = 8; // Move F | |||

int Rgo = 6; // move to the R | |||

int Lgo = 4; // move to the L | |||

int Bgo = 2; // move B | |||

void setup() | |||

{ | |||

Serial.begin(9600); // Define motor output pin | |||

pinMode(pinLB,OUTPUT); // pin 12 | |||

pinMode(pinLF,OUTPUT); // pin 3 (PWM) | |||

pinMode(pinRB,OUTPUT); // pin 13 | |||

pinMode(pinRF,OUTPUT); // pin 11 (PWM) | |||

pinMode(inputPin, INPUT); // define input pin for sensor | |||

pinMode(outputPin, OUTPUT); // define output pin for sensor | |||

myservo.attach(9); // Define servo motor output pin to D9 (PWM) | |||

} | |||

void advance() // move forward | |||

{ | |||

digitalWrite(pinLB,LOW); // right wheel moves forward | |||

digitalWrite(pinRB, LOW); // left wheel moves forward | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void stopp() // stop | |||

{ | |||

digitalWrite(pinLB,HIGH); | |||

digitalWrite(pinRB,HIGH); | |||

analogWrite(pinLF,0); | |||

analogWrite(pinRF,0); | |||

} | |||

void right() // turn right (single wheel) | |||

{ | |||

digitalWrite(pinLB,HIGH); // wheel on the left moves forward | |||

digitalWrite(pinRB,LOW); // wheel on the right moves backward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void left() // turn left (single wheel) | |||

{ | |||

digitalWrite(pinLB,LOW); // wheel on the left moves backward | |||

digitalWrite(pinRB,HIGH); // wheel on the right moves forward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void back() // move backward | |||

{ | |||

digitalWrite(pinLB,HIGH); // motor moves to left rear | |||

digitalWrite(pinRB,HIGH); // motor moves to right rear | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void detection() // measure 3 angles (0.90.179) | |||

{ | |||

int delay_time = 250; // stabilizing time for servo motor after moving backward | |||

ask_pin_F(); // read the distance ahead | |||

if(Fspeedd < 10) // if distance ahead is <10cm | |||

{ | |||

stopp(); // clear data | |||

delay(100); | |||

back(); // move backward for 0.2S | |||

delay(200); | |||

} | |||

if(Fspeedd < 25) // if distance ahead is <25cm | |||

{ | |||

stopp(); | |||

delay(100); // clear data | |||

ask_pin_L(); // read distance on the left | |||

delay(delay_time); // stabilizing time for servo motor | |||

ask_pin_R(); // read distance on the right | |||

delay(delay_time); // stabilizing time for servo motor | |||

if(Lspeedd > Rspeedd) // if distance on the left is >distance on the right | |||

{ | |||

directionn = Lgo; // move to the L | |||

} | |||

if(Lspeedd <= Rspeedd) // if distance on the left is <= distance on the right | |||

{ | |||

directionn = Rgo; // move to the right | |||

} | |||

if (Lspeedd < 10 && Rspeedd < 10) // if distance on left and right are both <10cm | |||

{ | |||

directionn = Bgo; // move backward | |||

}} | |||

else // if distance ahead is >25cm | |||

{ | |||

directionn = Fgo; // move forward | |||

}} | |||

void ask_pin_F() // measure the distance ahead | |||

{ | |||

myservo.write(90); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Fdistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Fdistance= Fdistance/5.8/10; // convert time into distance (unit: cm) | |||

Fspeedd = Fdistance; // read the distance into Fspeedd | |||

} | |||

void ask_pin_L() // measure distance on the left | |||

{ | |||

myservo.write(5); | |||

delay(delay_time); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Ldistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Ldistance= Ldistance/5.8/10; // convert time into distance (unit: cm) | |||

Lspeedd = Ldistance; // read the distance into Lspeedd | |||

} | |||

void ask_pin_R() // measure distance on the right | |||

{ | |||

myservo.write(177); | |||

delay(delay_time); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Rdistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Rdistance= Rdistance/5.8/10; // convert time into distance (unit: cm) | |||

Rspeedd = Rdistance; // read the distance into Rspeedd | |||

} | |||

void loop() | |||

{ | |||

myservo.write(90); // home set the servo motor, ready for next measurement | |||

detection(); // measure the angle and determine which direction to move | |||

if(directionn == 2) // if directionn= 2 | |||

{ | |||

back(); | |||

delay(800); // go backward | |||

left() ; | |||

delay(200); // Move slightly to the left (to prevent stuck in dead end) | |||

} | |||

if(directionn == 6) // if directionn = 6 | |||

{ | |||

back(); | |||

delay(100); | |||

right(); | |||

delay(600); // turn right | |||

} | |||

if(directionn == 4) // if directionn = 4 | |||

{ | |||

back(); | |||

delay(600); | |||

left(); | |||

delay(600); // turn left | |||

} | |||

if(directionn == 8) // if directionn = 8 | |||

{ | |||

advance(); // move forward | |||

delay(100); | |||

} } | |||

</pre> | |||

'''Result'''<br> | |||

After power-on, the car runs and will avoid obstacle automatically when catching obstacle. | |||

=== '''Project 4: Bluetooth Control Tank Robot '''=== | |||

<br>[[File:73.png|500px|frameless|thumb]]<br> | |||

'''Introduction'''<br> | |||

This project is a tank robot system based on Bluetooth communication, including software and hardware design. The controller part is a UNO board. A Bluetooth module is used to receive the Bluetooth signal from the cellphone and feedback the signal to the UNO. UNO will analyze the signal to determine and control the motors movement to adjust car moving direction. Therefore the tank robot can be controlled by cellphone. | |||

'''Working Principle'''<br> | |||

1. The Bluetooth module is connected to UNO; the module communicates with cell phone through a Bluetooth APP. <br> | |||

2. The Bluetooth APP on the cell phone will pass information of “U”“D”“L”“R”“S” to the Bluetooth module. <br> | |||

3. The Bluetooth module will pass the information to the UNO, so the UNO can determine car movement according to the information received.<br> | |||

4. When the UNO receives a “U”, the car goes straight forward; when it receives a “D”, the car goes backward; “L” for turning left; “R” for turning right; and “S” for stop.<br> | |||

'''Bluetooth Usage'''<br> | |||

Connect main board +5V to Bluetooth VCC, GND to Bluetooth GND, TX to Bluetooth RX and RX to Bluetooth TX.<br> | |||

Remember to open the Bluetooth on your phone; when you open the Bluetooth APP, it will remind you.Pair up Bluetooth device on your phone, search and pair. <br> | |||

Pair up device, PIN No. is 1234. <br> | |||

Open Bluetooth APP and pair up Bluetooth device. After it’s paired, the Bluetooth module can communicate with cell phone. <br> | |||

<span style=color:red>Note: Before uploading test code, we can’t insert Bluetooth module, otherwise the program will fail to be uploaded. After uploading test code successfully, connect Bluetooth and Bluetooth module , pair and connect APP.</span> | |||

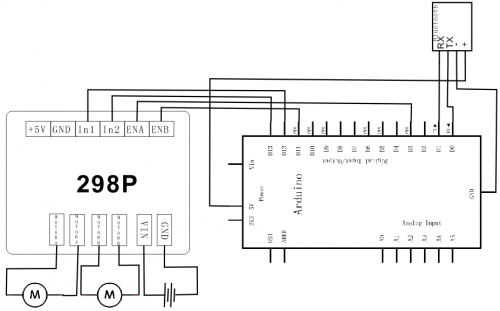

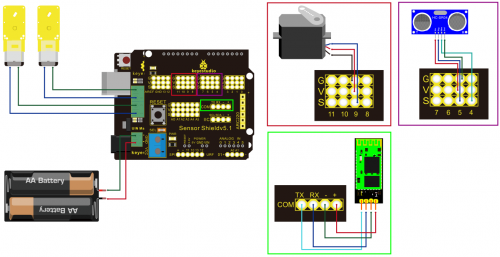

'''Schematic and Connection Diagram'''<br> | |||

<br>[[File:ks0071 2-3.png|500px|frameless|thumb]]<br> | |||

<br>[[File:74.png|500px|frameless|thumb]]<br> | |||

'''Sample Code'''<br> | |||

<pre> | |||

/* | |||

L = Left | |||

R = Right | |||

F = forward | |||

B = backward | |||

*/ | |||

int pinLB = 12; // define pin 12 | |||

int pinLF = 3; // define pin 3 | |||

int pinRB = 13; // define pin 13 | |||

int pinRF = 11; // define pin 11 | |||

int val; | |||

void setup() | |||

{ | |||

Serial.begin(9600); // define pin for motor output | |||

pinMode(pinLB,OUTPUT); // pin 12 | |||

pinMode(pinLF,OUTPUT); // pin 3 (PWM) | |||

pinMode(pinRB,OUTPUT); // pin 13 | |||

pinMode(pinRF,OUTPUT); // pin 11 (PWM) | |||

} | |||

void advance() // move forward | |||

{ | |||

digitalWrite(pinLB,LOW); // right wheel moves forward | |||

digitalWrite(pinRB, LOW); // left wheel moves forward | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void stopp() // stop | |||

{ | |||

digitalWrite(pinLB,HIGH); | |||

digitalWrite(pinRB,HIGH); | |||

analogWrite(pinLF,0); | |||

analogWrite(pinRF,0); | |||

} | |||

void right() // turn right (single wheel) | |||

{ | |||

digitalWrite(pinLB,HIGH); // left wheel moves forward | |||

digitalWrite(pinRB,LOW); // right wheel moves backward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void left() // turn left (single wheel) | |||

{ | |||

digitalWrite(pinLB,LOW); // left wheel moves forward | |||

digitalWrite(pinRB,HIGH); // right wheel moves backward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void back() // move backward | |||

{digitalWrite(pinLB,HIGH); // motor moves to left rear | |||

digitalWrite(pinRB,HIGH); // motor moves to right rear | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void loop() | |||

{ val=Serial.read(); | |||

if(val=='U')advance(); | |||

if(val=='D')back(); | |||

if(val=='L')left() ; | |||

if(val=='R')right(); | |||

if(val=='S')stopp(); | |||

} | |||

</pre> | |||

'''Result'''<br> | |||

Connected to Bluetooth APP, the movement of the car is controlled by the APP. | |||

=== '''Project 5: Ultrasonic Ranging Tank Robot '''=== | |||

<br>[[File:75.png|500px|frameless|thumb]]<br> | |||

'''Introduction'''<br> | |||

In project 3, we use the ultrasonic sensor module for the tank to realize obstacle avoidance function. In project 4, we use a HC-06 Bluetooth module for the tank, so the tank can be controlled form a cellphone terminal.<br> | |||

This project is based on project 3 and project 4. Here, we apply echo sounding method for the ranging. The trig end of ultrasonic sensor will launch ultrasonic wave in a specific direction. At the same time, the timer begins to count; when the ultrasonic wave encounters an obstacle, it’s reflected back; when the echo end receives the signal, the timer stops the count. With the traveling speed of the wave and the traveling time, we can calculate the distance between the launching point and the obstacle. <br> | |||

Also,we will use the HC-06 Bluetooth module for the Tank to communicate with the terminal. The tank will send the measured distance to the terminal, so we can clearly see the distance between the tank and the obstacle while the tank is moving. <br> | |||

This robot can be used in outdoor exploration or terrain exploration in a confined space. <br> | |||

'''Schematic and Connection Diagram'''<br> | |||

<br>[[File:ks0071 3-1.png|500px|frameless|thumb]]<br> | |||

<br>[[File:76.png|500px|frameless|thumb]]<br> | |||

'''Sample Code'''<br> | |||

<pre> | |||

/* | |||

L = Left | |||

R = Right | |||

F = forward | |||

B = backward | |||

*/ | |||

#include <Servo.h> | |||

int pinLB = 12; // define pin 12 | |||

int pinLF = 3; // define pin 3 | |||

int pinRB = 13; // define pin 13 | |||

int pinRF = 11; // define pin 11 | |||

int inputPin = 4; // define pin for sensor echo | |||

int outputPin =5; // define pin for sensor trig | |||

int Fspeedd = 0; // forward speed | |||

int Rspeedd = 0; // right speed | |||

int Lspeedd = 0; // left speed | |||

int directionn = 0; // forward=8 backward=2 left=4 right=6 | |||

Servo myservo; // set myservo | |||

int delay_time = 250; // settling time after steering servo motor moving B | |||

int Fgo = 8; // Move F | |||

int Rgo = 6; // move to the R | |||

int Lgo = 4; // move to the L | |||

int Bgo = 2; // move B | |||

void setup() | |||

{ | |||

Serial.begin(9600); // Define motor output pin | |||

pinMode(pinLB,OUTPUT); // pin 12 | |||

pinMode(pinLF,OUTPUT); // pin 3 (PWM) | |||

pinMode(pinRB,OUTPUT); // pin 13 | |||

pinMode(pinRF,OUTPUT); // pin 11 (PWM) | |||

pinMode(inputPin, INPUT); // define input pin for sensor | |||

pinMode(outputPin, OUTPUT); // define output pin for sensor | |||

myservo.attach(9); // Define servo motor output pin to D9 (PWM) | |||

} | |||

void advance() // move forward | |||

{ | |||

digitalWrite(pinLB,LOW); // right wheel moves forward | |||

digitalWrite(pinRB, LOW); // left wheel moves forward | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void stopp() // stop | |||

{ | |||

digitalWrite(pinLB,HIGH); | |||

digitalWrite(pinRB,HIGH); | |||

analogWrite(pinLF,0); | |||

analogWrite(pinRF,0); | |||

} | |||

void right() // turn right (single wheel) | |||

{ | |||

digitalWrite(pinLB,HIGH); // wheel on the left moves forward | |||

digitalWrite(pinRB,LOW); // wheel on the right moves backward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void left() // turn left (single wheel) | |||

{ | |||

digitalWrite(pinLB,LOW); // wheel on the left moves backward | |||

digitalWrite(pinRB,HIGH); // wheel on the right moves forward | |||

analogWrite(pinLF, 255); | |||

analogWrite(pinRF,255); | |||

} | |||

void back() // move backward | |||

{ | |||

digitalWrite(pinLB,HIGH); // motor moves to left rear | |||

digitalWrite(pinRB,HIGH); // motor moves to right rear | |||

analogWrite(pinLF,255); | |||

analogWrite(pinRF,255); | |||

} | |||

void detection() // measure 3 angles (0.90.179) | |||

{ | |||

int delay_time = 250; // stabilizing time for servo motor after moving backward | |||

ask_pin_F(); // read the distance ahead | |||

if(Fspeedd < 10) // if distance ahead is <10cm | |||

{ | |||

stopp(); // clear data | |||

delay(100); | |||

back(); // move backward for 0.2S | |||

delay(200); | |||

} | |||

if(Fspeedd < 25) // if distance ahead is <25cm | |||

{ | |||

stopp(); | |||

delay(100); // clear data | |||

ask_pin_L(); // read distance on the left | |||

delay(delay_time); // stabilizing time for servo motor | |||

ask_pin_R(); // read distance on the right | |||

delay(delay_time); // stabilizing time for servo motor | |||

if(Lspeedd > Rspeedd) // if distance on the left is >distance on the right | |||

{ | |||

directionn = Lgo; // move to the L | |||

} | |||

if(Lspeedd <= Rspeedd) // if distance on the left is <= distance on the right | |||

{ | |||

directionn = Rgo; // move to the right | |||

} | |||

if (Lspeedd < 10 && Rspeedd < 10) // if distance on left and right are both <10cm | |||

{ | |||

directionn = Bgo; // move backward | |||

} } | |||

else // if distance ahead is >25cm | |||

{ | |||

directionn = Fgo; // move forward | |||

}} | |||

void ask_pin_F() // measure the distance ahead | |||

{ | |||

myservo.write(90); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Fdistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Fdistance= Fdistance/5.8/10; // convert time into distance (unit: cm) | |||

Fspeedd = Fdistance; // read the distance into Fspeedd | |||

Serial.print("Fspeedd = "); | |||

Serial.print(Fspeedd ); | |||

Serial.println(" cm"); | |||

} | |||

void ask_pin_L() // measure distance on the left | |||

{ | |||

myservo.write(5); | |||

delay(delay_time); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Ldistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Ldistance= Ldistance/5.8/10; // convert time into distance (unit: cm) | |||

Lspeedd = Ldistance; // read the distance into Lspeedd | |||

Serial.print("Lspeedd = "); | |||

Serial.print(Lspeedd ); | |||

Serial.print(" cm "); | |||

} | |||

void ask_pin_R() // measure distance on the right | |||

{ | |||

myservo.write(177); | |||

delay(delay_time); | |||

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs | |||

delayMicroseconds(2); | |||

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs | |||

delayMicroseconds(10); | |||

digitalWrite(outputPin, LOW); // keep transmitting low level signal | |||

float Rdistance = pulseIn(inputPin, HIGH); // read the time in between | |||

Rdistance= Rdistance/5.8/10; // convert time into distance (unit: cm) | |||

Rspeedd = Rdistance; // read the distance into Rspeedd | |||

Serial.print(" Rspeedd = "); | |||

Serial.print(Rspeedd ); | |||

Serial.println(" cm"); | |||

} | |||

void loop() | |||

{ | |||

myservo.write(90); // home set the servo motor, ready for next measurement | |||

detection(); // measure the angle and determine which direction to move | |||

if(directionn == 2) // if directionn= 2 | |||

{ | |||

back(); | |||

delay(800); // go backward | |||

left() ; | |||

delay(200); // Move slightly to the left (to prevent stuck in dead end) | |||

} | |||

if(directionn == 6) // if directionn = 6 | |||

{ back(); | |||

delay(100); | |||

right(); | |||

delay(600); // turn right | |||

} | |||

if(directionn == 4) // if directionn = 4 | |||

{ back(); | |||

delay(600); | |||

left(); | |||

delay(600); // turn left | |||

} | |||

if(directionn == 8) // if directionn = 8 | |||

{ advance(); // move forward | |||

delay(100); | |||

}} | |||

</pre> | |||

'''Result'''<br> | |||

Connected to Bluetooth APP, the movement of the car is controlled by the APP. | |||

==Resources == | |||

'''Video''' <br> | |||

http://video.keyestudio.com/KS0071/ | |||

'''Download APP, Library, and code:'''<br> | |||

https://fs.keyestudio.com/KS0071 | |||

<br> | |||

==Buy from == | |||

'''Official Website''' | |||

http://www.keyestudio.com/keyes-mini-tank-robot.html | |||

'''Amazon Store''' | |||

https://www.amazon.com/Keyestudio-Bluetooth-Robot-Aluminum-Arduino/dp/B01F38JY7I/ | |||

[[category:Smart Car]] | |||

Latest revision as of 12:09, 6 September 2021

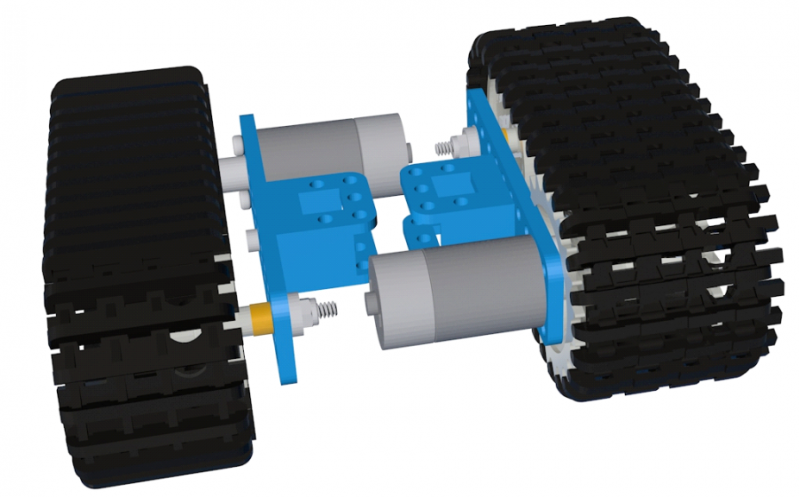

keyestudio Mini Tank Robot

Introduction

Mini tank robot is a learning application development system of microcontroller based on Arduino. It has functions such as ultrasonic obstacle avoidance, bluetooth remotecontrol. This kit contains many interesting programs. It can also be expanded with external circuit modules to have further functions. This kit is designed to help you interestingly learn Arduino. You can learn Arduino MCU development ability while having fun.

Parameters

1. Motor parameters: 6V, 150rpm/min

2. Use L298P driver module for motor control.

3. Equipped with Ultrasonic module, can detect whether there are obstacles ahead, and the distance between the Tank robot and the obstacles to realize obstacle avoidance function.

4. Equipped with Bluetooth wireless module, can remotely control the robot after pairing with mobile phone Bluetooth.

5. Can be connected to external 7 ~ 12V power supply; with various sensor modules, it can realize various functions.

Component List

Application of Arduino

Introduction

What’s Arduino?

Arduino is an open-source hardware project platform. This platform includes a circuit board with simple I/O function and program development environment software. It can be used to develop interactive products. For example, it can read signals of multiple switches and sensors, and control light, servo motor and other various physical devices. It’s widely applied in robot field.

Arduino installation and program upload:

First, download the Arduino development software, click below hyperlink:

arduino-1.5.6-r2-windows.rar

Downloaded file is a arduino-1.5.6-r2-windows.zip compressed folder, unzip it to your hard drive.

Double click Arduino-1.5.6 .exe. Click “I agree”;

Click “Next”;

And then “Install”;

Wait for the installation to be completed, click close.

Below figure is what Arduino 1.5.6 looks like.

Next, let’s install Arduino driver.

For different operating system, there may be slight difference in installation method. Below is an example in WIN 7.

When you connect Arduino Uno to your computer at the first time, right click “Computer” —> “Properties”—> “Device manager”, you can see “Unknown devices”.

Click “Unknown devices”, select “Update Driver software”.

In this page, click “Browse my computer for driver software”.

Find the “drivers” file.

Click “Next”; select “Install this driver software anyway” to begin the installation.

Installation completed; click “Close”.

After driver is installed, go to “Device manager” again. Right click “Computer” —> “Properties”—> “Device manager”, you can see UNO device as below figure shows, also with the Com port info.

Following is a sketch uploading example called “Hello World!”.

First, open Arduino IDE. In this example sketch, we program Arduino to display “Hello World!” on serial monitor when it receives a specific character string “R”; also the on-board D13 LED will blink once each time it receives “R”.

First, set up board; In “Tools”, select “Arduino Uno”.

Next, set up COM port; In “Tools”, select “COM3”.

After selection, you can see indicated area is the same with settings in “Device manager”.

Copy the example sketch and paste it to the IDE; click “Verify ![]() ” to check compiling mistakes; click “Upload

” to check compiling mistakes; click “Upload ![]() ” to upload the program to the board.

” to upload the program to the board.

After uploading is done, open “serial monitor![]() ”; enter “R”; click “Send”, the serial monitor will display “Hello World!” and the D13 LED will blink once.

”; enter “R”; click “Send”, the serial monitor will display “Hello World!” and the D13 LED will blink once.

Congratulations! Your first sketch uploading is successful!

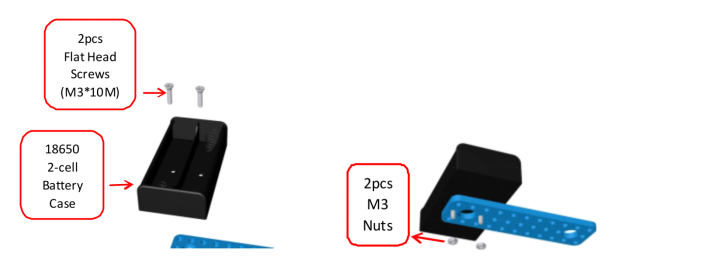

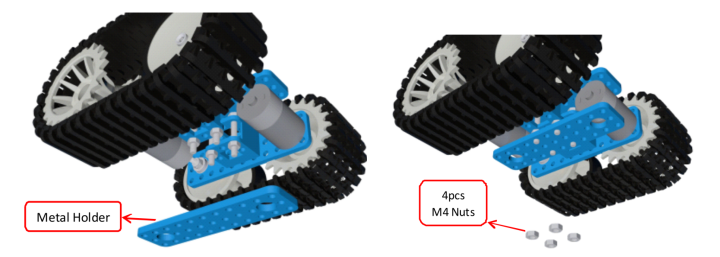

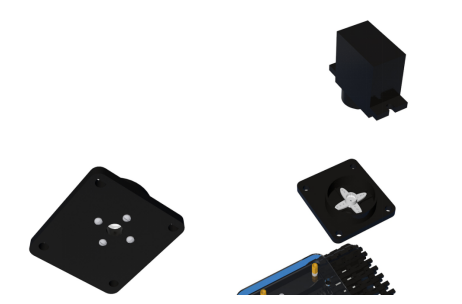

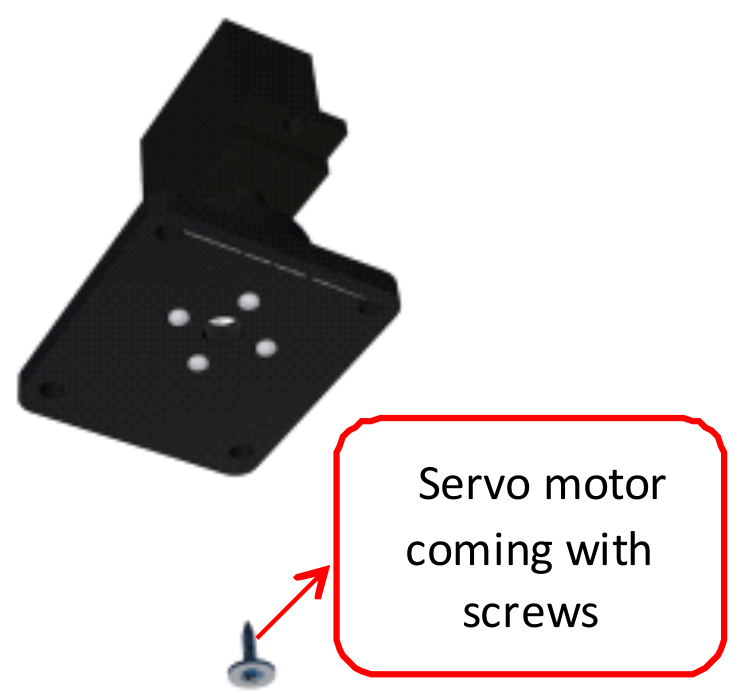

Installation Method

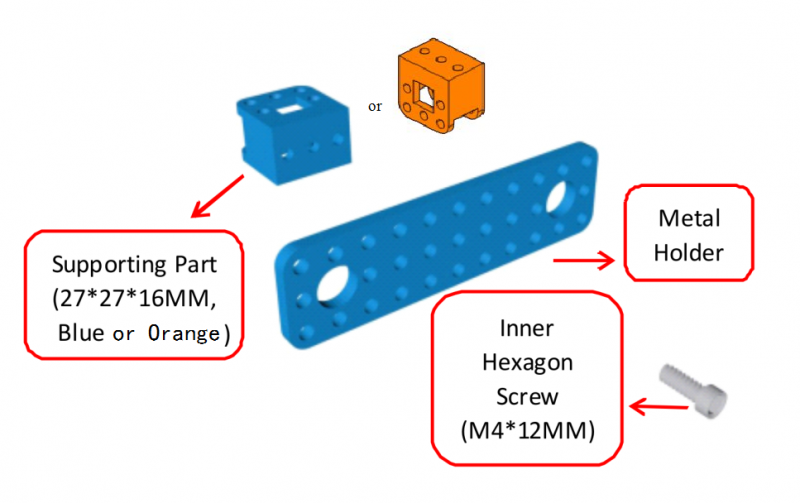

1. Attach the supporting part to the metal holder with a inner hexagon screw.

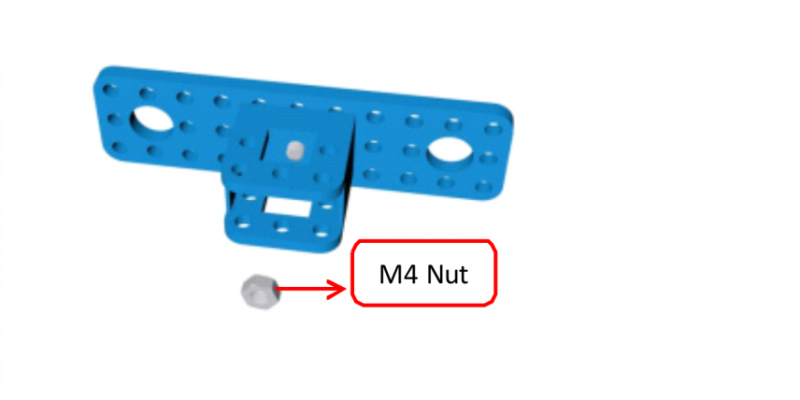

Then add a nut to fix the screw.

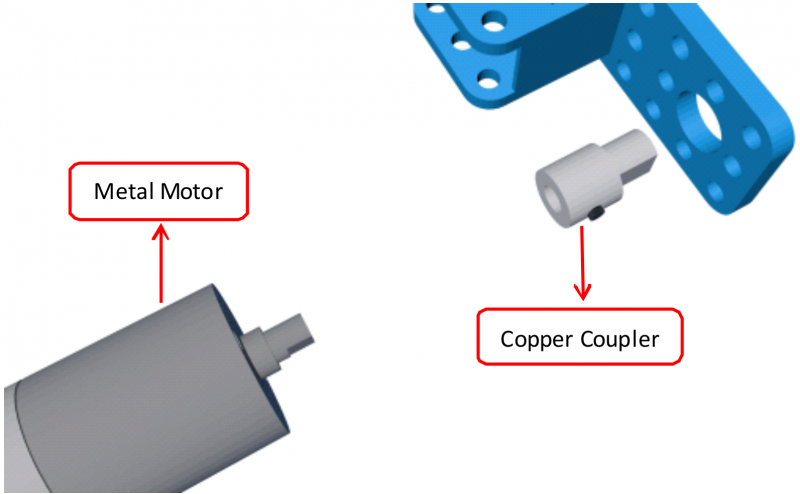

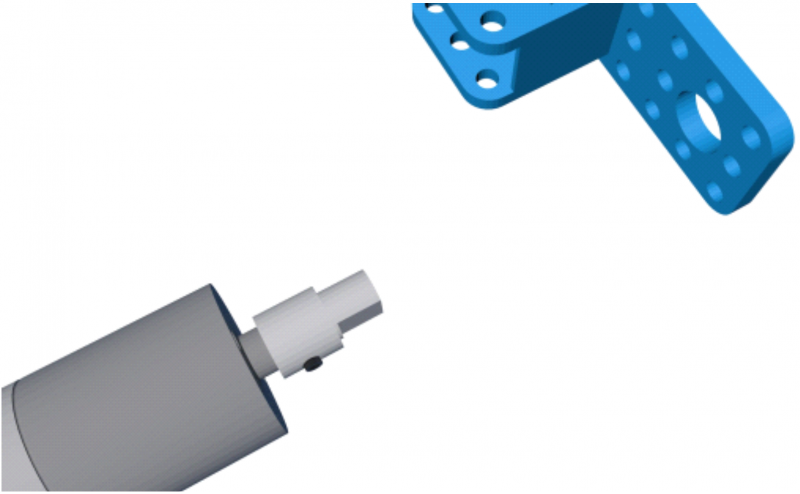

2.Plug a copper coupler into a metal motor;

Then, reinforce them with a screwdriver.

3.Fix the metal motor to the metal holder with two inner hexagon screws.

4. Plug a tank driver wheel into the metal motor and reinforce them with an inner hexagon screw.

5. The tank load-bearing wheel is bolted to one screw and a copper bush.

Then fix them with a flange bearing.

6.Put the tank driver wheel through a screw hole of the metal holder and the load-bearing wheel right into the caterpillar.

Next screw a flange bearing to fix the metal holder and the wheel.

Then put a nut upon the flange bearing to reinforce.

Finally combine the left part with the right part together.

7.Attach the battery case to another metal holder with two flat head screws, using two nuts to fix them.

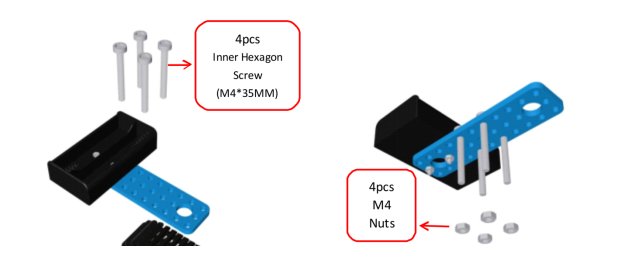

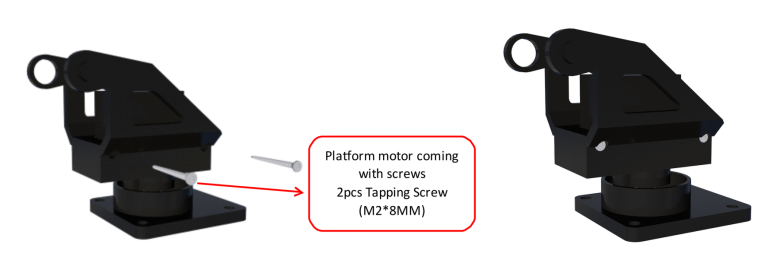

8. Fix four inner hexagon screws to the metal holder using 4 nuts.

9. The battery is bolted to the supporting part with four nuts.

10.Attach another metal holder to the four screws and then reinforce them with four nuts.

11.Plug four inner hexagon screws through the supporting part.

Then screw 4 copper bushes to the four hexagon screws.

12.Screw 8 copper bushes upon a acrylic board using 8 inner hexagon screws.

13.The acrylic board is bolted to the four copper bushes with 4 hexagon screws.

14. Cut the white cross to fit the size of the black cross and the attach the white one to the black one.

Then fix the white cross with four tapping screws.

15.Put the blue platform upon the cross,

Then fix the platform using a tapping screw.

16. Attach the two holder together, and then fix them with two tapping screws.

17.The whole platform is bolted to four short copper bushes using four inner hexagon screws.

18.Tie the ultrasonic sensor up with the black holder using two pieces of ribbon.

19.Attach the REV4 controller to the other four short copper bushes using four inner hexagon screws.

20. Plug the L298P shield into the controller;

Next plug the V5 sensor shield into the L298P shield;

Finally plug the bluetooth into the serial ports on the V5 shield.

Project Details

Project 1: Ultrasonic Sensor

Introduction

The HC-SR04 Ultrasonic Sensor is a very affordable proximity distance sensor that has been used mainly for object avoidance in various robotics projects. It essentially gives your Arduino eyes spacial awareness and can prevent your robot from crashing or falling off a table. It has also been used in turret applications, water level sensing, and even as a parking sensor. This simple project will use the HC-SR04 sensor with an Arduino and a Processing sketch to provide a neat little interactive display on your computer screen.

Specification

Working Voltage: DC 5V

Working Current: 15mA

Working Frequency: 40Hz

Max Range: 4m

Min Range: 2cm

Measuring Angle: 15 degree

Trigger Input Signal: 10µS TTL pulse

Echo Output Signal Input TTL lever signal and the range in proportion

Sample Code

Wiring Method:

VCC to Arduino 5v

GND to Arduino GND

Echo to Arduino pin 4

Trig to Arduino pin 5

#define echoPin 4 // Echo Pin

#define trigPin 5 // Trigger Pin

#define LEDPin 13 // Onboard LED

int maximumRange = 200; // Maximum range needed

int minimumRange = 0; // Minimum range needed

long duration, distance; // Duration used to calculate distance

void setup() {

Serial.begin (9600);

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

pinMode(LEDPin, OUTPUT); // Use LED indicator (if required)

}

void loop() {

/* The following trigPin/echoPin cycle is used to determine the

distance of the nearest object by bouncing soundwaves off of it. */

digitalWrite(trigPin, LOW);

delayMicroseconds(2);

digitalWrite(trigPin, HIGH);

delayMicroseconds(10);

digitalWrite(trigPin, LOW);

duration = pulseIn(echoPin, HIGH);

//Calculate the distance (in cm) based on the speed of sound.

distance = duration/58.2;

if (distance >= maximumRange || distance <= minimumRange){

/* Send a negative number to computer and Turn LED ON

to indicate "out of range" */

Serial.println("-1");

digitalWrite(LEDPin, HIGH);

}

else {

/* Send the distance to the computer using Serial protocol, and

turn LED OFF to indicate successful reading. */

Serial.println(distance);

digitalWrite(LEDPin, LOW);

}

//Delay 50ms before next reading.

delay(50);

}

Result

After connection and uploading, when ultrasonic sensor senses obstacle within sensing area, it is measuring the distance between itself and obstacle and the value of distance is displayed on serial monitor as shown in below figure.

Project 2: Bluetooth Module

Introduction

This Bluetooth module can easily achieve serial wireless data transmission. Its operating frequency is among the most popular 2.4GHz ISM frequency band (i.e. Industrial, scientific and medical). It adopts Bluetooth 2.1+EDR standard. In Bluetooth 2.1, signal transmit time of different devices stands at a 0.5 seconds interval so that the workload of bluetooth chip can be reduced substantially and more sleeping time can be saved for bluetooth. This module is set with serial interface, which is easy-to-use and simplifying overall design/development cycle.

Specification

Bluetooth Protocol: Bluetooth 2.1+ EDR standard

USB Protocol: USB v1.1/2.0

Operating Frequency: 2.4GHz ISM frequency band

Modulation Mode: Gauss frequency Shift Keying

Transmit Power: ≤ 4dBm, second stage

Sensitivity: ≤-84dBm at 0.1% Bit Error Rate

Transmission Speed: 2.1Mbps(Max)/160 kbps(Asynchronous); 1Mbps/1Mbps(Synchronous)

Safety Feature: Authentication and encryption

Supported Configuration: Bluetooth serial port (major and minor)

Supply Voltage: 5V DC 50mA

Operating Temperature: -20 to 55℃

Note: Before uploading test code, we can’t insert Bluetooth module, otherwise the program will fail to be uploaded. After uploading test code successfully, connect Bluetooth and Bluetooth module , pair and connect APP.

Sample Code

int val;

int ledpin=13;

void setup()

{

Serial.begin(9600);

pinMode(ledpin,OUTPUT);

} void loop()

{ val=Serial.read();

if(val=='a')

{

digitalWrite(ledpin,HIGH);

delay(250);

digitalWrite(ledpin,LOW);

delay(250);

Serial.println("keyestudio");

}}

Result

After powered up, power indicator D1 is on, and LED on Bluetooth module is blinking; open Bluetooth on mobile phone, pair them, input 1234, and finish pairing as shown in Figure 1 ; open APP—Bluetooth serial communication assistant, connect it to Bluetooth, select normal mode, complete connection, and LED on Bluetooth module is on as shown in Figure 2; input an “a” in the assistant, and display “keyesdudio” in it as shown in Figure 3.

Figure 1 - - - - - - - - - - - - Figure 2 - - - - - - - - - - - - - Figure 3

Project 3: Obstacle Avoidance Tank

Introduction

This project is a simple obstacle avoidance tank robot system based on Arduino, including the software and hardware design. The controller part is a UNO board. Ultrasonic sensor and servo motors are used to detect whether there are obstacles ahead, and feedback the signal to UNO. UNO will analyze the signal to determine and control the motors movement to adjust Tank moving direction. Therefore the tank robot can automatically avoid obstacles.

Working Principle

Ultrasonic ranging: the controller sends out a a high level signal of more than 10μs, when the output pin receives the high level signal, the timer will be on; when the signal changes to low level, we can read the time period of the timer, which is the time used for this ultrasonic wave transceiving. Together with its transmission speed, we can calculate the distance.

After we use the ultrasonic sensor to detect the distance from an obstacle, we can control the movement of the Tank according to the data.

If the distance from the obstacle is < 10cm, the Tank moves backward; if the distance is >=25cm, the Tank moves forward; if the distance is <25cm, we control the movement of the servo motors to measure the distance of the left and right. If both the distance are <10cm, the Tank moves backward; if the distance are both >= 10cm, and distance on the left is more than the distance on the right, the Tank moves to the left; if distance on the left is <= the distance on the right, the Tank moves to the right.

Schematic and Connection Diagram

Sample Code

/*

L = Left

R = Right

F = forward

B = backward

*/

#include <Servo.h>

int pinLB = 12; // define pin 12

int pinLF = 3; // define pin 3

int pinRB = 13; // define pin 13

int pinRF = 11; // define pin 11

////////////////////////////////

int inputPin = 4; // define pin for sensor echo

int outputPin =5; // define pin for sensor trig

int Fspeedd = 0; // forward speed

int Rspeedd = 0; // right speed

int Lspeedd = 0; // left speed

int directionn = 0; // forward=8 backward=2 left=4 right=6

Servo myservo; // set myservo

int delay_time = 250; // settling time after steering servo motor moving B

int Fgo = 8; // Move F

int Rgo = 6; // move to the R

int Lgo = 4; // move to the L

int Bgo = 2; // move B

void setup()

{

Serial.begin(9600); // Define motor output pin

pinMode(pinLB,OUTPUT); // pin 12

pinMode(pinLF,OUTPUT); // pin 3 (PWM)

pinMode(pinRB,OUTPUT); // pin 13

pinMode(pinRF,OUTPUT); // pin 11 (PWM)

pinMode(inputPin, INPUT); // define input pin for sensor

pinMode(outputPin, OUTPUT); // define output pin for sensor

myservo.attach(9); // Define servo motor output pin to D9 (PWM)

}

void advance() // move forward

{

digitalWrite(pinLB,LOW); // right wheel moves forward

digitalWrite(pinRB, LOW); // left wheel moves forward

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void stopp() // stop

{

digitalWrite(pinLB,HIGH);

digitalWrite(pinRB,HIGH);

analogWrite(pinLF,0);

analogWrite(pinRF,0);

}

void right() // turn right (single wheel)

{

digitalWrite(pinLB,HIGH); // wheel on the left moves forward

digitalWrite(pinRB,LOW); // wheel on the right moves backward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void left() // turn left (single wheel)

{

digitalWrite(pinLB,LOW); // wheel on the left moves backward

digitalWrite(pinRB,HIGH); // wheel on the right moves forward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void back() // move backward

{

digitalWrite(pinLB,HIGH); // motor moves to left rear

digitalWrite(pinRB,HIGH); // motor moves to right rear

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void detection() // measure 3 angles (0.90.179)

{

int delay_time = 250; // stabilizing time for servo motor after moving backward

ask_pin_F(); // read the distance ahead

if(Fspeedd < 10) // if distance ahead is <10cm

{

stopp(); // clear data

delay(100);

back(); // move backward for 0.2S

delay(200);

}

if(Fspeedd < 25) // if distance ahead is <25cm

{

stopp();

delay(100); // clear data

ask_pin_L(); // read distance on the left

delay(delay_time); // stabilizing time for servo motor

ask_pin_R(); // read distance on the right

delay(delay_time); // stabilizing time for servo motor

if(Lspeedd > Rspeedd) // if distance on the left is >distance on the right

{

directionn = Lgo; // move to the L

}

if(Lspeedd <= Rspeedd) // if distance on the left is <= distance on the right

{

directionn = Rgo; // move to the right

}

if (Lspeedd < 10 && Rspeedd < 10) // if distance on left and right are both <10cm

{

directionn = Bgo; // move backward

}}

else // if distance ahead is >25cm

{

directionn = Fgo; // move forward

}}

void ask_pin_F() // measure the distance ahead

{

myservo.write(90);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Fdistance = pulseIn(inputPin, HIGH); // read the time in between

Fdistance= Fdistance/5.8/10; // convert time into distance (unit: cm)

Fspeedd = Fdistance; // read the distance into Fspeedd

}

void ask_pin_L() // measure distance on the left

{

myservo.write(5);

delay(delay_time);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Ldistance = pulseIn(inputPin, HIGH); // read the time in between

Ldistance= Ldistance/5.8/10; // convert time into distance (unit: cm)

Lspeedd = Ldistance; // read the distance into Lspeedd

}

void ask_pin_R() // measure distance on the right

{

myservo.write(177);

delay(delay_time);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Rdistance = pulseIn(inputPin, HIGH); // read the time in between

Rdistance= Rdistance/5.8/10; // convert time into distance (unit: cm)

Rspeedd = Rdistance; // read the distance into Rspeedd

}

void loop()

{

myservo.write(90); // home set the servo motor, ready for next measurement

detection(); // measure the angle and determine which direction to move

if(directionn == 2) // if directionn= 2

{

back();

delay(800); // go backward

left() ;

delay(200); // Move slightly to the left (to prevent stuck in dead end)

}

if(directionn == 6) // if directionn = 6

{

back();

delay(100);

right();

delay(600); // turn right

}

if(directionn == 4) // if directionn = 4

{

back();

delay(600);

left();

delay(600); // turn left

}

if(directionn == 8) // if directionn = 8

{

advance(); // move forward

delay(100);

} }

Result

After power-on, the car runs and will avoid obstacle automatically when catching obstacle.

Project 4: Bluetooth Control Tank Robot

Introduction

This project is a tank robot system based on Bluetooth communication, including software and hardware design. The controller part is a UNO board. A Bluetooth module is used to receive the Bluetooth signal from the cellphone and feedback the signal to the UNO. UNO will analyze the signal to determine and control the motors movement to adjust car moving direction. Therefore the tank robot can be controlled by cellphone.

Working Principle

1. The Bluetooth module is connected to UNO; the module communicates with cell phone through a Bluetooth APP.

2. The Bluetooth APP on the cell phone will pass information of “U”“D”“L”“R”“S” to the Bluetooth module.

3. The Bluetooth module will pass the information to the UNO, so the UNO can determine car movement according to the information received.

4. When the UNO receives a “U”, the car goes straight forward; when it receives a “D”, the car goes backward; “L” for turning left; “R” for turning right; and “S” for stop.

Bluetooth Usage

Connect main board +5V to Bluetooth VCC, GND to Bluetooth GND, TX to Bluetooth RX and RX to Bluetooth TX.

Remember to open the Bluetooth on your phone; when you open the Bluetooth APP, it will remind you.Pair up Bluetooth device on your phone, search and pair.

Pair up device, PIN No. is 1234.

Open Bluetooth APP and pair up Bluetooth device. After it’s paired, the Bluetooth module can communicate with cell phone.

Note: Before uploading test code, we can’t insert Bluetooth module, otherwise the program will fail to be uploaded. After uploading test code successfully, connect Bluetooth and Bluetooth module , pair and connect APP.

Schematic and Connection Diagram

Sample Code

/*

L = Left

R = Right

F = forward

B = backward

*/

int pinLB = 12; // define pin 12

int pinLF = 3; // define pin 3

int pinRB = 13; // define pin 13

int pinRF = 11; // define pin 11

int val;

void setup()

{

Serial.begin(9600); // define pin for motor output

pinMode(pinLB,OUTPUT); // pin 12

pinMode(pinLF,OUTPUT); // pin 3 (PWM)

pinMode(pinRB,OUTPUT); // pin 13

pinMode(pinRF,OUTPUT); // pin 11 (PWM)

}

void advance() // move forward

{

digitalWrite(pinLB,LOW); // right wheel moves forward

digitalWrite(pinRB, LOW); // left wheel moves forward

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void stopp() // stop

{

digitalWrite(pinLB,HIGH);

digitalWrite(pinRB,HIGH);

analogWrite(pinLF,0);

analogWrite(pinRF,0);

}

void right() // turn right (single wheel)

{

digitalWrite(pinLB,HIGH); // left wheel moves forward

digitalWrite(pinRB,LOW); // right wheel moves backward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void left() // turn left (single wheel)

{

digitalWrite(pinLB,LOW); // left wheel moves forward

digitalWrite(pinRB,HIGH); // right wheel moves backward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void back() // move backward

{digitalWrite(pinLB,HIGH); // motor moves to left rear

digitalWrite(pinRB,HIGH); // motor moves to right rear

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void loop()

{ val=Serial.read();

if(val=='U')advance();

if(val=='D')back();

if(val=='L')left() ;

if(val=='R')right();

if(val=='S')stopp();

}

Result

Connected to Bluetooth APP, the movement of the car is controlled by the APP.

Project 5: Ultrasonic Ranging Tank Robot

Introduction

In project 3, we use the ultrasonic sensor module for the tank to realize obstacle avoidance function. In project 4, we use a HC-06 Bluetooth module for the tank, so the tank can be controlled form a cellphone terminal.

This project is based on project 3 and project 4. Here, we apply echo sounding method for the ranging. The trig end of ultrasonic sensor will launch ultrasonic wave in a specific direction. At the same time, the timer begins to count; when the ultrasonic wave encounters an obstacle, it’s reflected back; when the echo end receives the signal, the timer stops the count. With the traveling speed of the wave and the traveling time, we can calculate the distance between the launching point and the obstacle.

Also,we will use the HC-06 Bluetooth module for the Tank to communicate with the terminal. The tank will send the measured distance to the terminal, so we can clearly see the distance between the tank and the obstacle while the tank is moving.

This robot can be used in outdoor exploration or terrain exploration in a confined space.

Schematic and Connection Diagram

Sample Code

/*

L = Left

R = Right

F = forward

B = backward

*/

#include <Servo.h>

int pinLB = 12; // define pin 12

int pinLF = 3; // define pin 3

int pinRB = 13; // define pin 13

int pinRF = 11; // define pin 11

int inputPin = 4; // define pin for sensor echo

int outputPin =5; // define pin for sensor trig

int Fspeedd = 0; // forward speed

int Rspeedd = 0; // right speed

int Lspeedd = 0; // left speed

int directionn = 0; // forward=8 backward=2 left=4 right=6

Servo myservo; // set myservo

int delay_time = 250; // settling time after steering servo motor moving B

int Fgo = 8; // Move F

int Rgo = 6; // move to the R

int Lgo = 4; // move to the L

int Bgo = 2; // move B

void setup()

{

Serial.begin(9600); // Define motor output pin

pinMode(pinLB,OUTPUT); // pin 12

pinMode(pinLF,OUTPUT); // pin 3 (PWM)

pinMode(pinRB,OUTPUT); // pin 13

pinMode(pinRF,OUTPUT); // pin 11 (PWM)

pinMode(inputPin, INPUT); // define input pin for sensor

pinMode(outputPin, OUTPUT); // define output pin for sensor

myservo.attach(9); // Define servo motor output pin to D9 (PWM)

}

void advance() // move forward

{

digitalWrite(pinLB,LOW); // right wheel moves forward

digitalWrite(pinRB, LOW); // left wheel moves forward

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void stopp() // stop

{

digitalWrite(pinLB,HIGH);

digitalWrite(pinRB,HIGH);

analogWrite(pinLF,0);

analogWrite(pinRF,0);

}

void right() // turn right (single wheel)

{

digitalWrite(pinLB,HIGH); // wheel on the left moves forward

digitalWrite(pinRB,LOW); // wheel on the right moves backward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void left() // turn left (single wheel)

{

digitalWrite(pinLB,LOW); // wheel on the left moves backward

digitalWrite(pinRB,HIGH); // wheel on the right moves forward

analogWrite(pinLF, 255);

analogWrite(pinRF,255);

}

void back() // move backward

{

digitalWrite(pinLB,HIGH); // motor moves to left rear

digitalWrite(pinRB,HIGH); // motor moves to right rear

analogWrite(pinLF,255);

analogWrite(pinRF,255);

}

void detection() // measure 3 angles (0.90.179)

{

int delay_time = 250; // stabilizing time for servo motor after moving backward

ask_pin_F(); // read the distance ahead

if(Fspeedd < 10) // if distance ahead is <10cm

{

stopp(); // clear data

delay(100);

back(); // move backward for 0.2S

delay(200);

}

if(Fspeedd < 25) // if distance ahead is <25cm

{

stopp();

delay(100); // clear data

ask_pin_L(); // read distance on the left

delay(delay_time); // stabilizing time for servo motor

ask_pin_R(); // read distance on the right

delay(delay_time); // stabilizing time for servo motor

if(Lspeedd > Rspeedd) // if distance on the left is >distance on the right

{

directionn = Lgo; // move to the L

}

if(Lspeedd <= Rspeedd) // if distance on the left is <= distance on the right

{

directionn = Rgo; // move to the right

}

if (Lspeedd < 10 && Rspeedd < 10) // if distance on left and right are both <10cm

{

directionn = Bgo; // move backward

} }

else // if distance ahead is >25cm

{

directionn = Fgo; // move forward

}}

void ask_pin_F() // measure the distance ahead

{

myservo.write(90);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Fdistance = pulseIn(inputPin, HIGH); // read the time in between

Fdistance= Fdistance/5.8/10; // convert time into distance (unit: cm)

Fspeedd = Fdistance; // read the distance into Fspeedd

Serial.print("Fspeedd = ");

Serial.print(Fspeedd );

Serial.println(" cm");

}

void ask_pin_L() // measure distance on the left

{

myservo.write(5);

delay(delay_time);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Ldistance = pulseIn(inputPin, HIGH); // read the time in between

Ldistance= Ldistance/5.8/10; // convert time into distance (unit: cm)

Lspeedd = Ldistance; // read the distance into Lspeedd

Serial.print("Lspeedd = ");

Serial.print(Lspeedd );

Serial.print(" cm ");

}

void ask_pin_R() // measure distance on the right

{

myservo.write(177);

delay(delay_time);

digitalWrite(outputPin, LOW); // ultrasonic sensor transmit low level signal 2μs

delayMicroseconds(2);

digitalWrite(outputPin, HIGH); // ultrasonic sensor transmit high level signal10μs, at least 10μs

delayMicroseconds(10);

digitalWrite(outputPin, LOW); // keep transmitting low level signal

float Rdistance = pulseIn(inputPin, HIGH); // read the time in between

Rdistance= Rdistance/5.8/10; // convert time into distance (unit: cm)

Rspeedd = Rdistance; // read the distance into Rspeedd

Serial.print(" Rspeedd = ");

Serial.print(Rspeedd );

Serial.println(" cm");

}

void loop()

{

myservo.write(90); // home set the servo motor, ready for next measurement

detection(); // measure the angle and determine which direction to move

if(directionn == 2) // if directionn= 2

{

back();

delay(800); // go backward

left() ;

delay(200); // Move slightly to the left (to prevent stuck in dead end)

}

if(directionn == 6) // if directionn = 6

{ back();

delay(100);

right();

delay(600); // turn right

}

if(directionn == 4) // if directionn = 4

{ back();

delay(600);

left();

delay(600); // turn left

}

if(directionn == 8) // if directionn = 8

{ advance(); // move forward

delay(100);

}}

Result

Connected to Bluetooth APP, the movement of the car is controlled by the APP.

Resources

Video

http://video.keyestudio.com/KS0071/

Download APP, Library, and code:

https://fs.keyestudio.com/KS0071

Buy from

Official Website

http://www.keyestudio.com/keyes-mini-tank-robot.html

Amazon Store

https://www.amazon.com/Keyestudio-Bluetooth-Robot-Aluminum-Arduino/dp/B01F38JY7I/