Ks0399(400, 401) keyestudio 37 in 1 Sensor V2.0 Kit for Arduino

-Sensor kit for Arduino

-Based on open-source hardware

-37 kinds of sensors/modules

-To build interactive projects

Kit Introduction

This is an Arduino 37 in 1 sensor learning kit developed by Keyestudio. You will have a set of Arduino's most common and useful electronic sensors and modules.

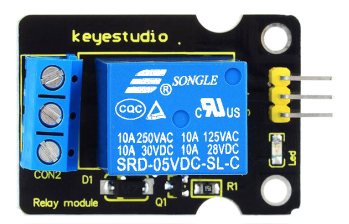

Inside this box, there are digital and analog sensors, and also some special modules such as ultrasonic, Joystick, relay, acceleration modules, etc.

For each module, there is clear connection diagram and sample code. So even if you are totally new at this, you can get started easily.

The sample codes for this sensor kit are based on ARDUINO because it's open source and easy. And if you are good at this, you can also apply this kit to other MCU development platform, such as 51, STM32, Raspberries Pi. The working principle is pretty much the same.

You may learn about Arduino from basic projects to more complex projects. Now, let us embrace this fascinating world of ARDUINO and learn together!

Kit List

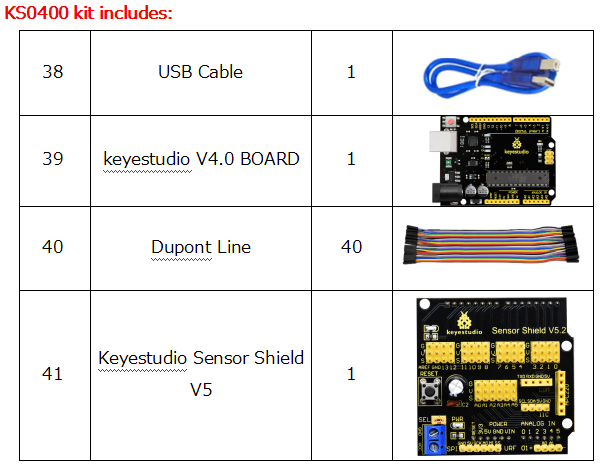

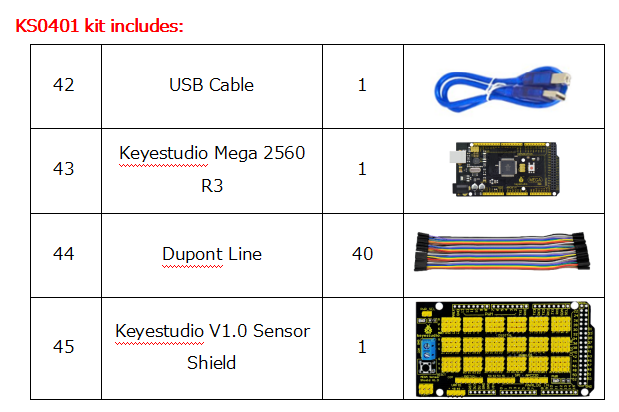

Note: KS0399 kit with no board; KS0400 kit with V4.0; KS0401 kit with 2560 MEGA R3

Getting Started with Arduino

Installing Arduino Software

When you get the V4.0 development board, first you should install the Arduino software and driver.

We usually use the Windows software Arduino 1.5.6 version. You can download it from the link below:

https://www.arduino.cc/en/Main/OldSoftwareReleases#1.5.x

Or you can browse the ARDUINO website to download the latest version from this link, https://www.arduino.cc, pop up the following interface.

Then click the SOFTWARE on the browse bar, you will have two options ONLINE TOOLS and DOWNLOADS.

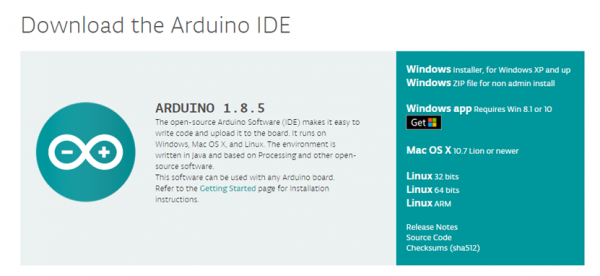

Click DOWNLOADS, it will appear the latest software version of ARDUINO 1.8.5 shown as below.

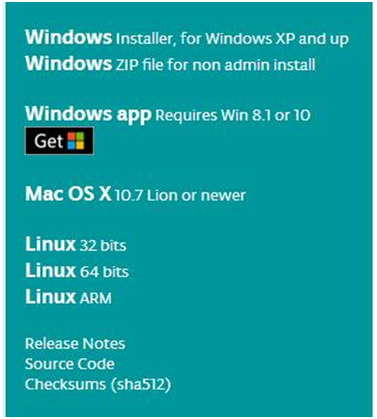

In this software page, on the right side you can see the version of development software for different operating systems. ARDUINO has a powerful compatibility. You should download the software that is compatible with the operating system of your computer.

We will take WINDOWS system as an example here. There are also two options under Windows system, one is installed version, the other is non-installed version.

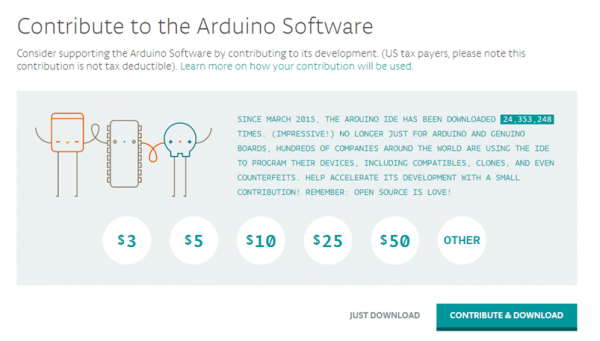

For simple installed version, first click Windows Installer, you will get the following page.

This way you just need to click JUST DOWNLOAD, then click the downloaded file to install it.

For non-installed version, first click Windows ZIP file, you will also get the pop-up interface as the above figure.

Click JUST DOWNLOAD, and when the ZIP file is downloaded well to your computer, you can directly unzip the file and click the icon of ARDUINO software to start it.

Installing Arduino (Windows)

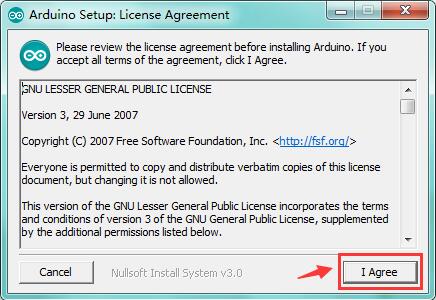

Install Arduino with the exe. Installation package. Here we provide you with Arduino-1.5.6-r2-windows package, you can directly click the icon to install it.

Click“I Agree”to see the following interface.

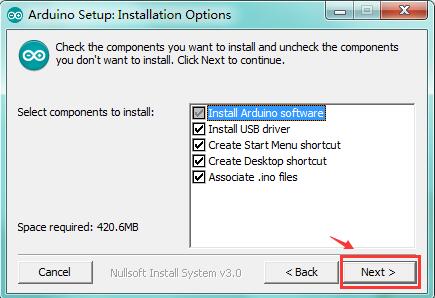

Click “Next”. Pop up the interface below.

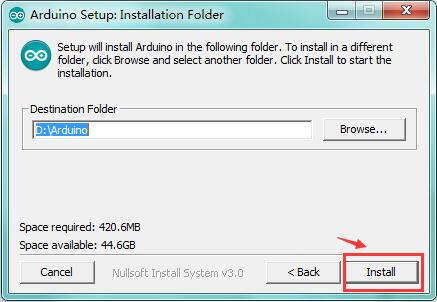

You can press Browse… to choose an installation path or directly type in the directory you want.

Then click “Install” to initiate installation.

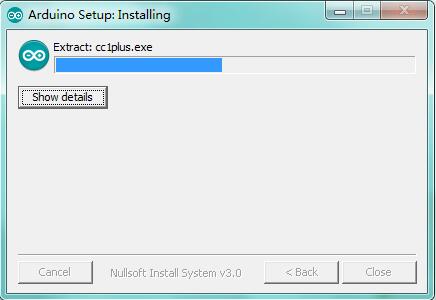

Wait for the installing process, if appear the interface of Window Security, just continue to click Install to finish the installation.

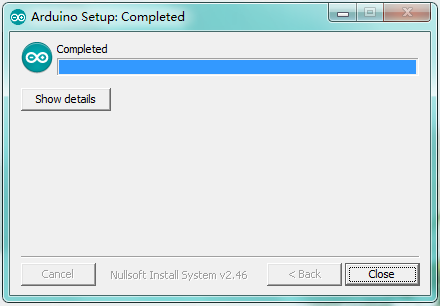

All right, up to now, you have completed the Arduino setup! The following icon will appear on your PC desktop.

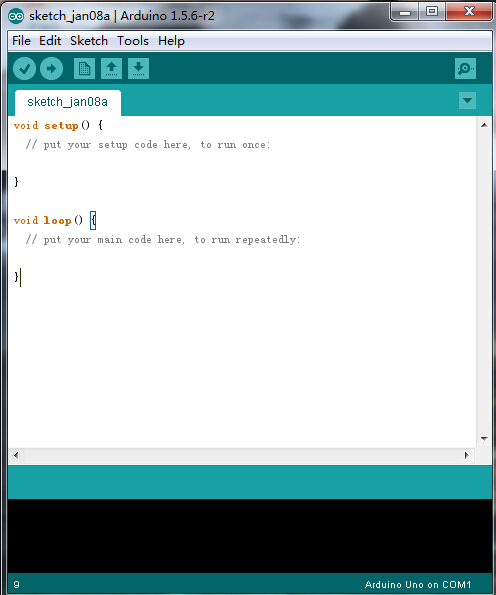

Double-click the icon of Arduino to enter the desired development environment shown as below.

The functions of each button on the Toolbar are listed below:

![]()

Installing Driver

Next, we will introduce the driver installation for development board. The driver installation may have slight differences in different computer systems. So in the following let’s move on to the driver installation in the WIN 7 system.

The Arduino folder contains both the Arduino program itself and the drivers that allow the Arduino to be connected to your computer by a USB cable. Before we launch the Arduino software, you are going to install the USB drivers.

Plug one end of your USB cable into the Arduino and the other into a USB socket on your computer.

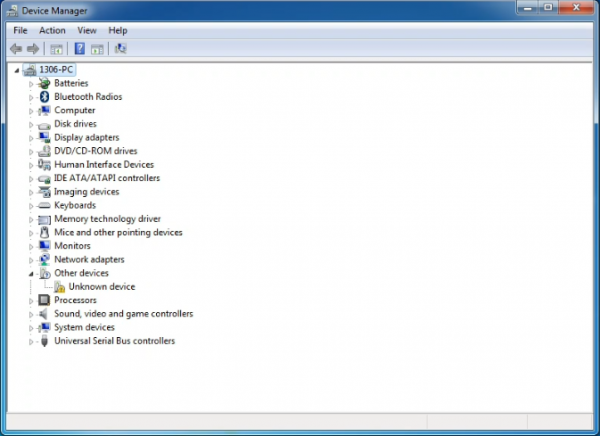

When you connect the V4.0 board to your computer at the first time, right click the icon of your “Computer” —>for “Properties”—> click “Device manager”, under “Other Devices”, you should see an icon for “Unknown device” with a little yellow warning triangle next to it. This is your Arduino.

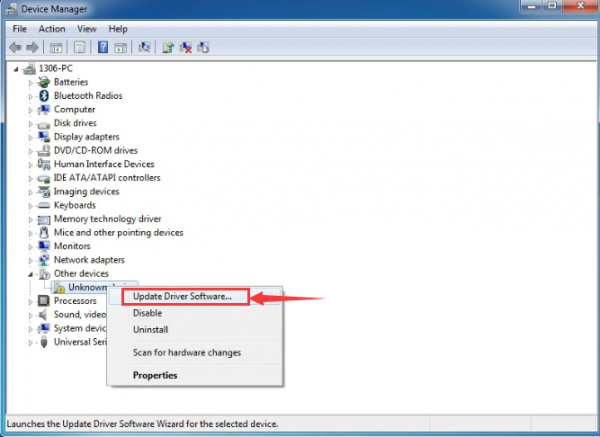

Then right-click on the device and select the top menu option (Update Driver Software...) shown as the figure below..

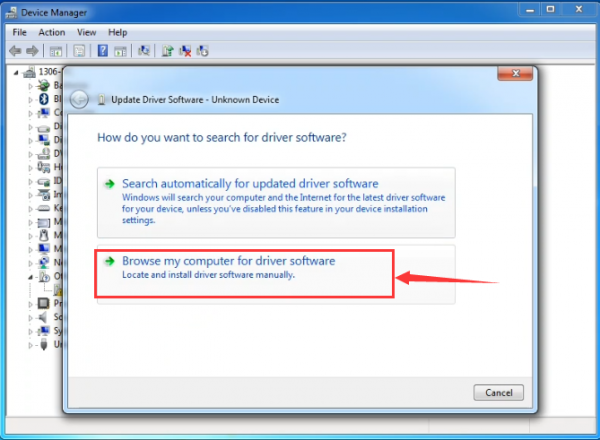

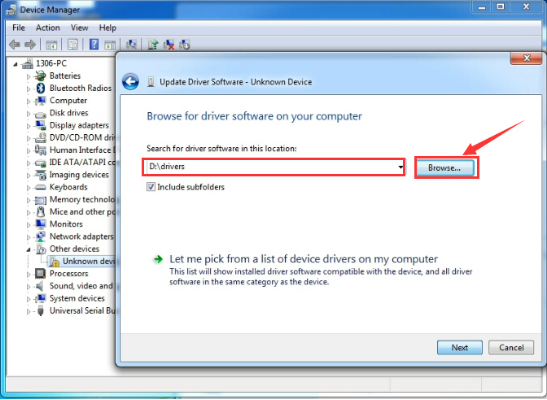

It will then be prompted to either “Search Automatically for updated driversoftware” or “Browse my computer for driver software”. Shown as below. In this page, select “Browse my computer for driver software”.

After that, select the option to browseand navigate to the “drivers” folder of Arduino installation.

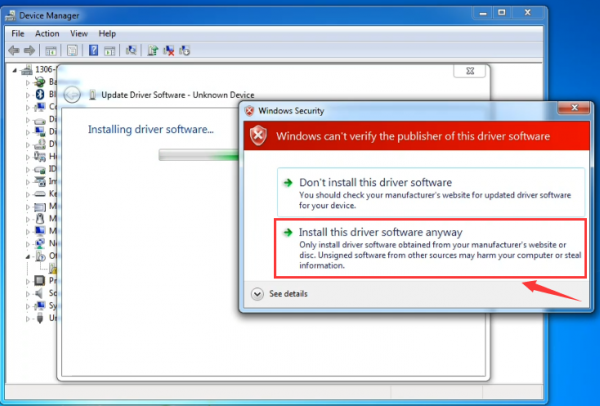

Click “Next” and you may get a security warning, if so, allow the software to be installed. Shown as below.

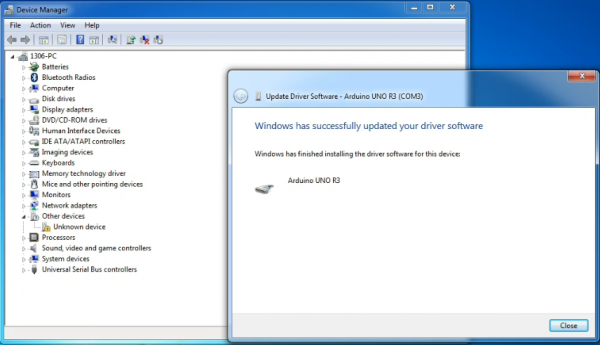

Once the software has been installed, you will get a confirmation message. Installation completed, click “Close”.

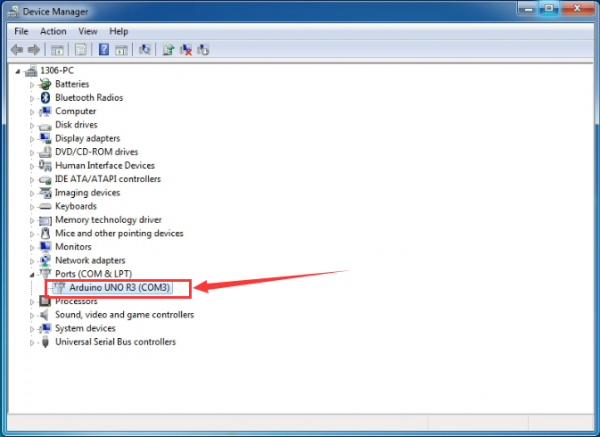

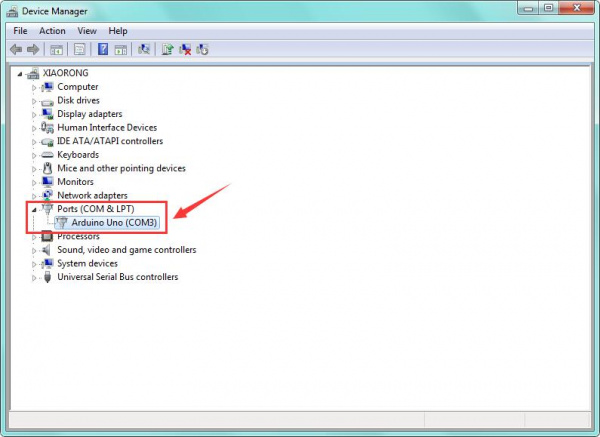

Up to now, the driver is installed well. Then you can right click “Computer” —>“Properties”—>“Device manager”, you should see the device as the figure shown below.

Displaying Hello World

Overview

It is very simple. You can use only a main board and a USB cable to display the “Hello World!”. It is a communication experiment between the control board and PC. This is an entry experiment for you to enter the Arduino programming world.

Note that need to use a serial communication software, Arduino IDE.

In the above part, you can check the detailed use of Arduino IDE.

Component Required

- V4.0 control board*1

- USB cable*1

Component Introduction

Keyestudio V4.0 development board is a microcontroller board based on the ATmega328P (datasheet), fully compatible with ARDUINO UNO. It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started.

Connect It Up

Connect the V4.0 board to your computer using the USB cable. The green power LED should go on.

Upload the Code

Below is an example code for displaying the Hello World!

int val;

int ledpin=13;

void setup()

{

Serial.begin(9600);

pinMode(ledpin,OUTPUT);

}

void loop()

{

val=Serial.read();

if(val=='R')

{

digitalWrite(ledpin,HIGH);

delay(500);

digitalWrite(ledpin,LOW);

delay(500);

Serial.println("Hello World!");

}

}

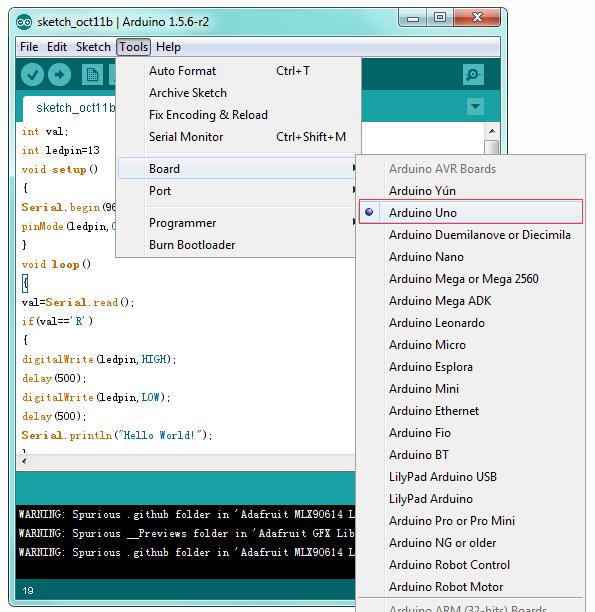

Select the Arduino Board

Open the Arduino IDE, you’ll need to click the “Tools”, then select the Board that corresponds to your Arduino.

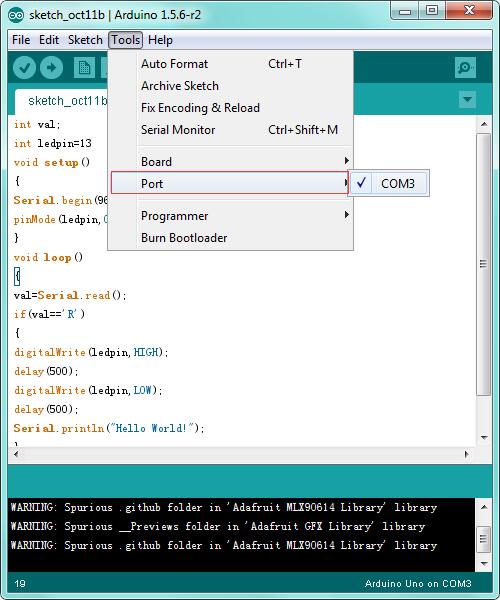

Select your serial port

Select the serial device of the Arduino board from the Tools | Serial Port menu.

Note: to avoid errors, the COM Port should keep the same as the Ports shown on Device Manager.

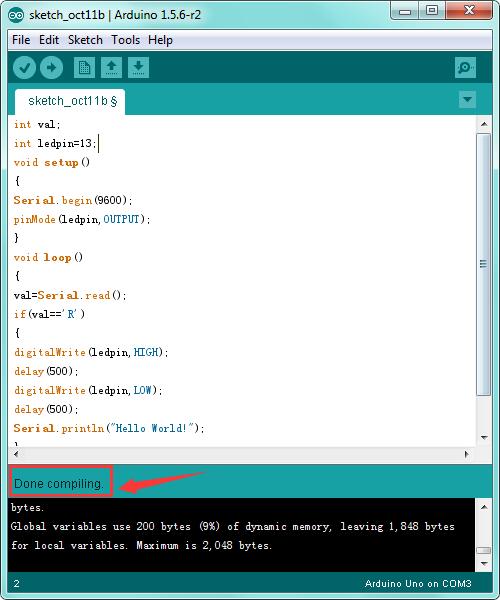

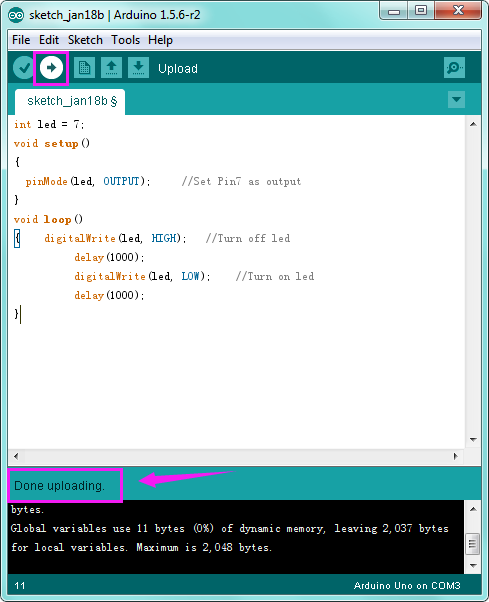

Then click verify button to check the errors. If compiling successfully, the message "Done compiling." will appear in the status bar.

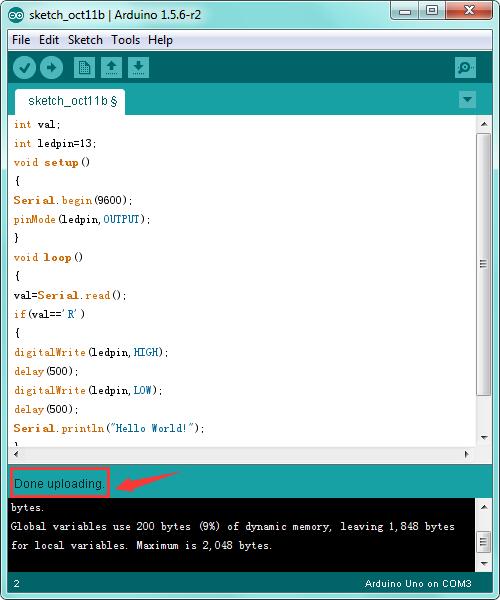

After that, click the “Upload” button to upload the code. Wait a few seconds - you should see the RX and TX leds on the board flashing. If the upload is successful, the message "Done uploading." will appear in the status bar.

(Note: If you have an Arduino Mini, NG, or other board, you'll need to physically present the reset button on the board immediately before pressing the upload button.)

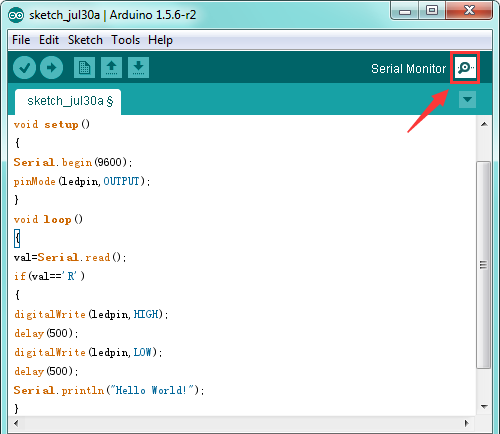

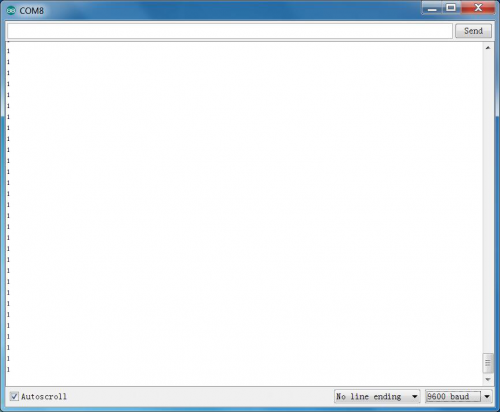

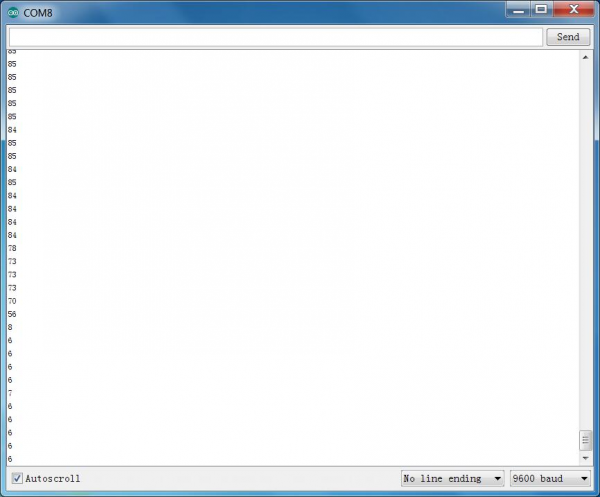

Open the Serial Monitor

After that, click the serial monitor button to open the serial monitor.

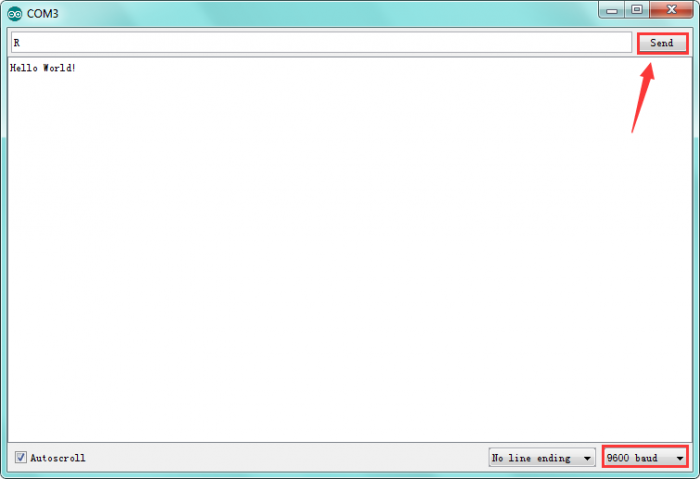

Then set the baud rate as 9600, enter an “R” and click Send, you should see the RX led on the board blink once, and then D13 led blink once, finally "Hello World!" is showed on the monitor, and TX led blink once.

Congrats! Your first simple program is complete.

Project Details

Project 1: LED Flash

Introduction

LED has wide applications. Most signal lights we saw in our daily life use LED as its major light source. In today’s experiment, we are going to use Arduino to make LED module flashing.

Components list

- Arduino UNO * 1

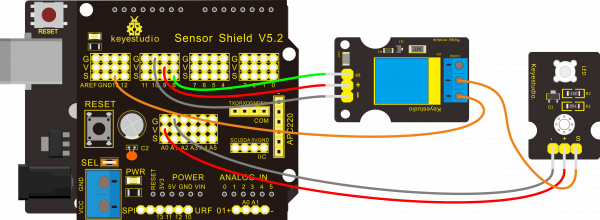

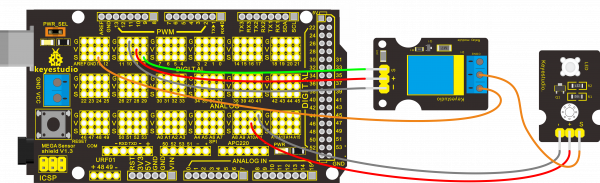

- keyestudio Sensor Shield V5* 1

- LED module * 1

- Jumper wire *3

- USB Cable* 1

Components Introduction

This is a special LED module. When you connect it to ARDUINO development board, after program, it can emit beautiful light. Of course, you can also control it using PWM. It will be like fireflies at night. Isn’t cool? We can also combine it with other sensors to do interesting interactive experiments.

Specifications

- Control interface: Digital

- Operating voltage: DC 3.3-5V

- Pin pitch:2.54mm

- Emitting color: white

Hardware Connection

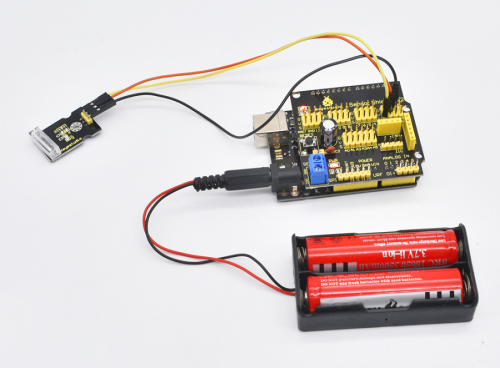

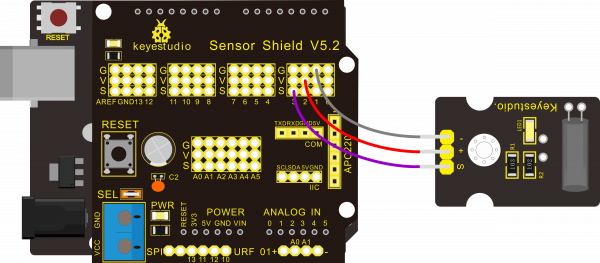

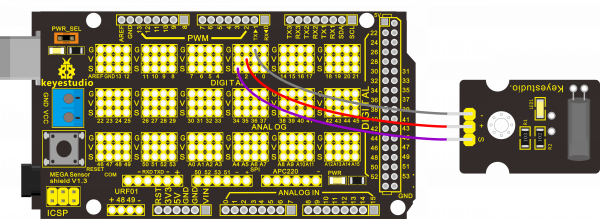

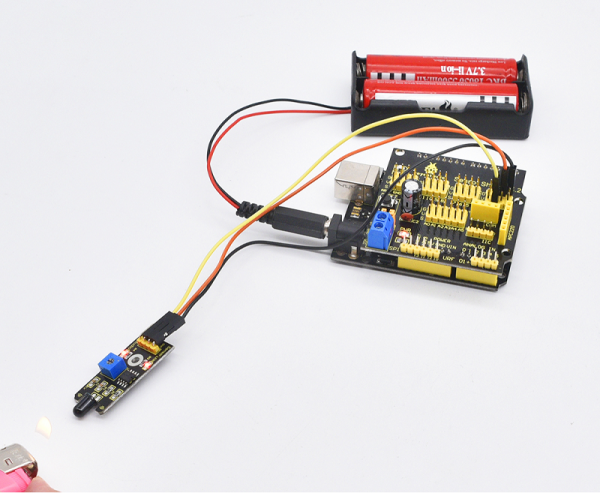

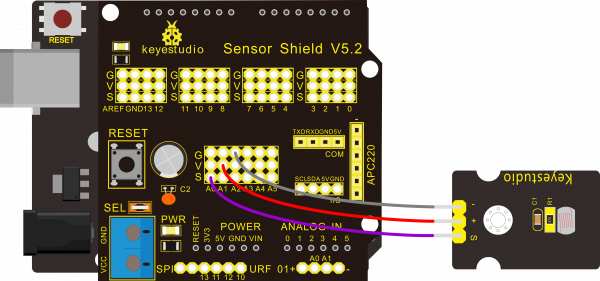

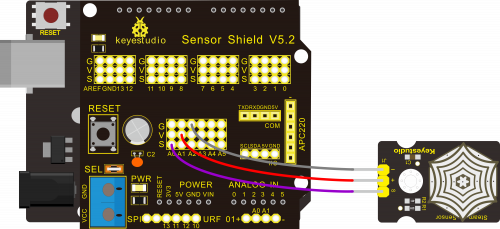

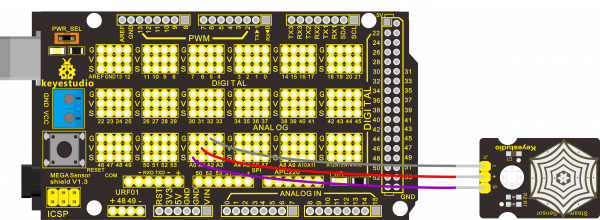

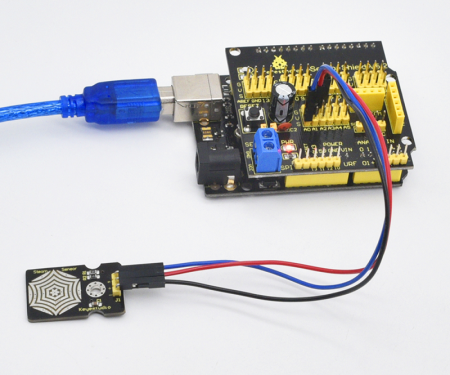

Connect the negative pin of LED module to GND, positive pin to VCC (3.3-5V), Signal pin to digital pin 7.

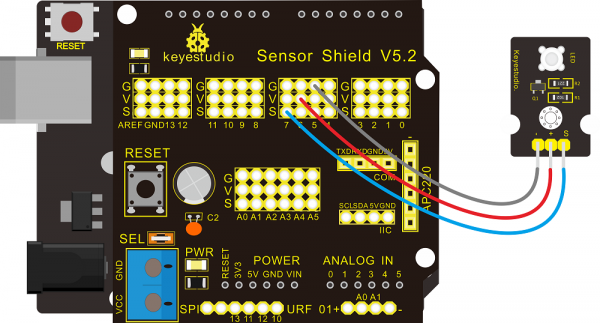

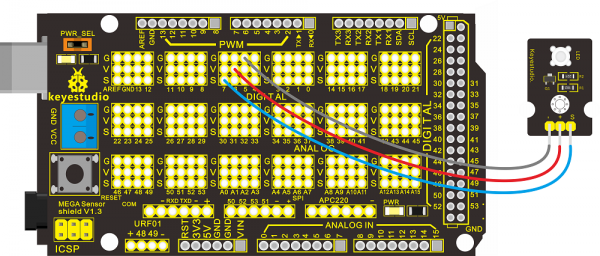

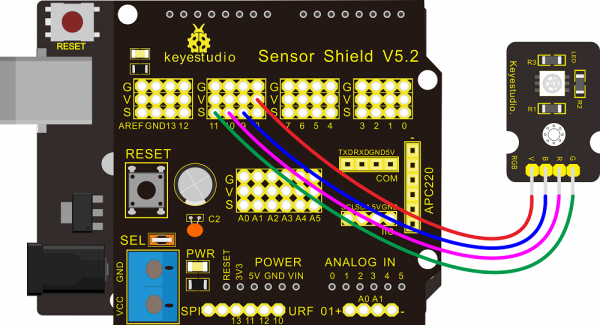

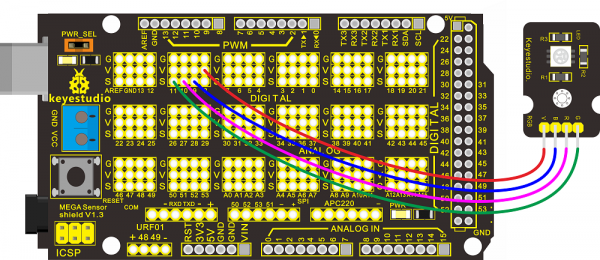

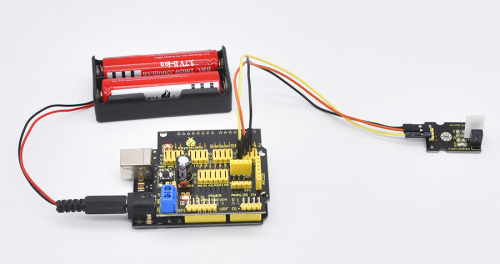

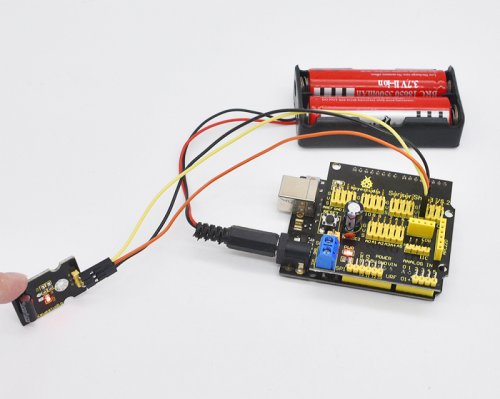

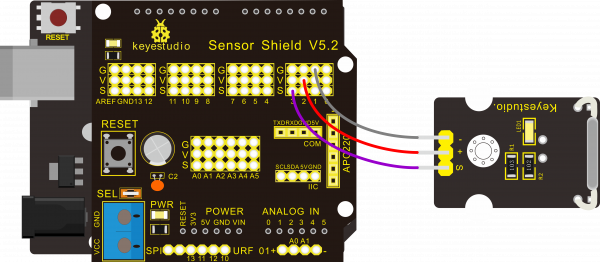

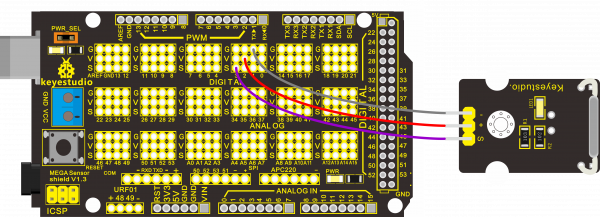

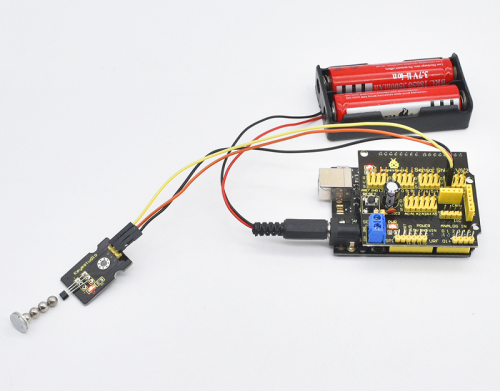

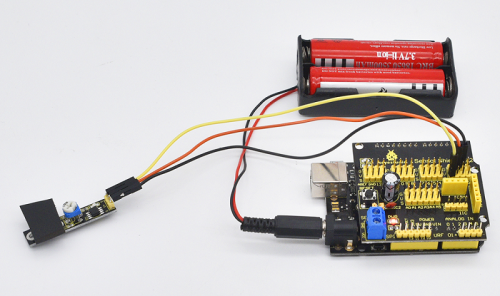

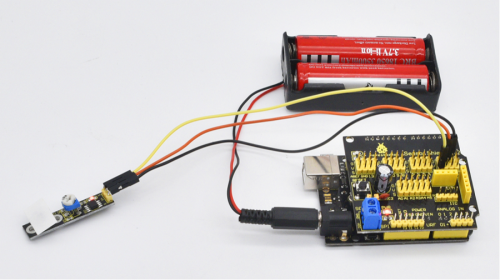

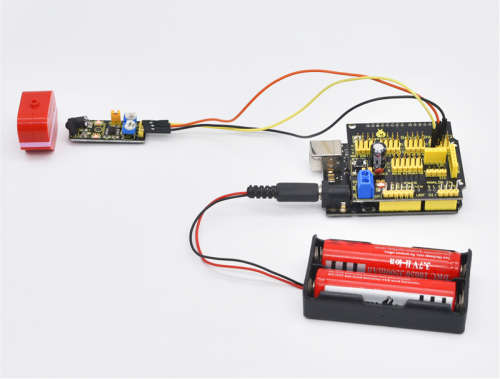

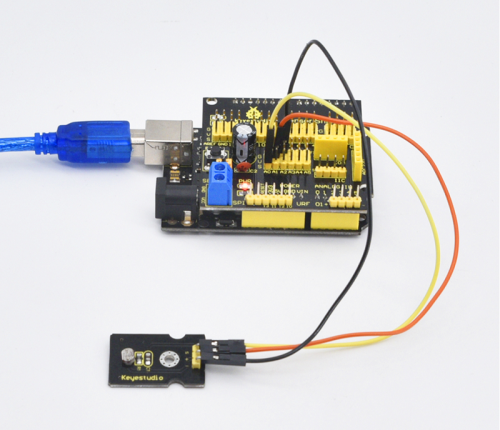

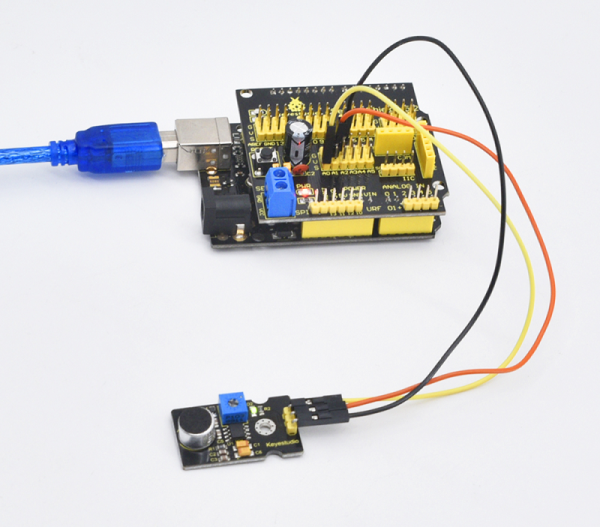

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board, then connect the LED module.

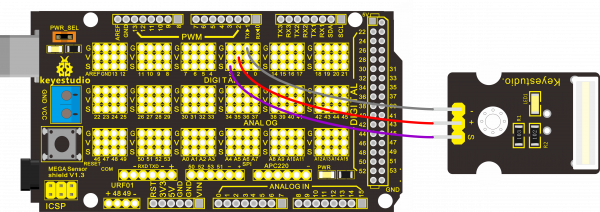

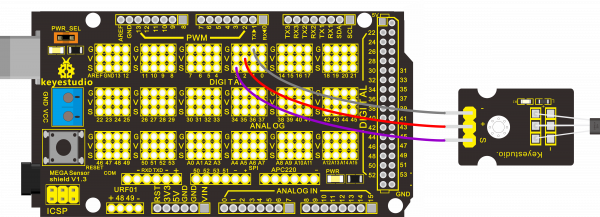

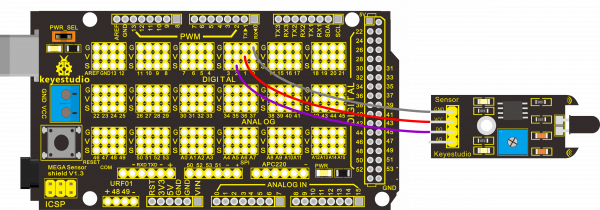

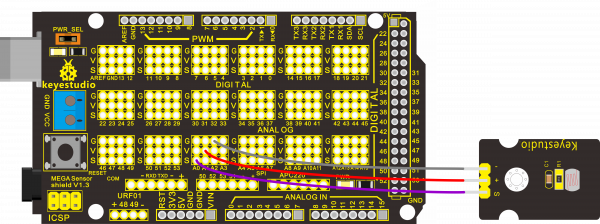

For Mega 2560 connection:

Stack the Sensor Shield V5 onto the Mega 2560 board, then connect the LED module.

Sample Code

int led = 7;

void setup()

{

pinMode(led, OUTPUT); //Set Pin7 as output

}

void loop()

{ digitalWrite(led, HIGH); //Turn off led

delay(1000);

digitalWrite(led, LOW); //Turn on led

delay(1000);

}

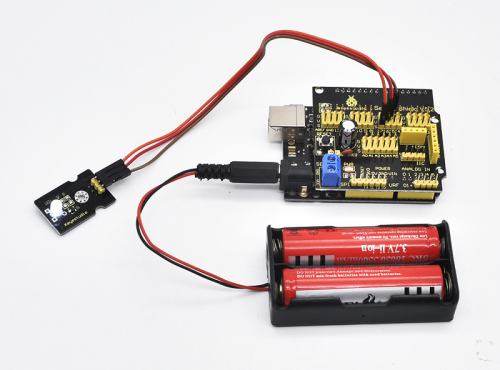

Experiment Result

Done uploading the code, you can see the LED on the module flashing for one second then off for one second, repeatedly.

If it is not, go back and check your operations.

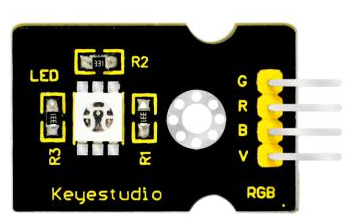

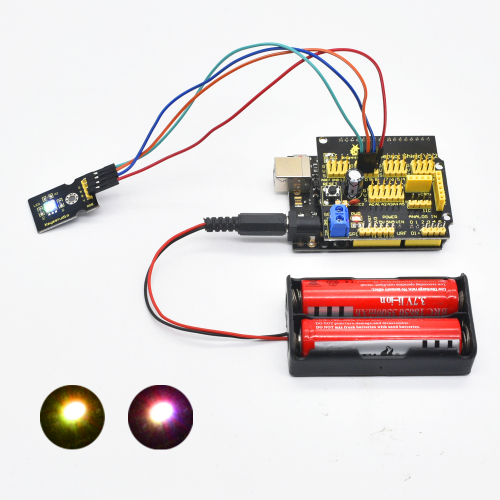

Project 2: RGB LED

Introduction

This is a full-color LED module, which contains 3 basic colors-red, green and blue. They can be seen as separate LED lights.

After program, we can turn them on and off by sequence. We can also use PWM analog output to mix the three colors to generate different colors.

Specification

- Color: red, green and blue

- Brightness: High

- Voltage: 5V

- Input: digital level

Hardware Connection

To begin with, you need to prepare the following parts before connection:

- Arduino Board*1

- keyestudio Sensor Shield V5* 1

- RGB LED module *1

- USB Cable*1

- Jumper Wire*4

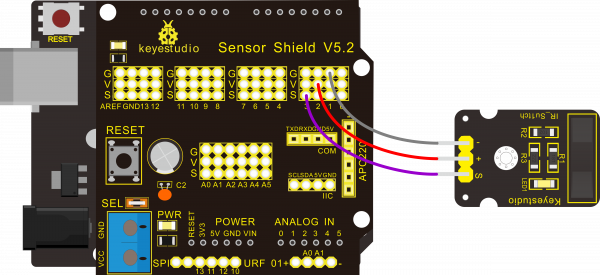

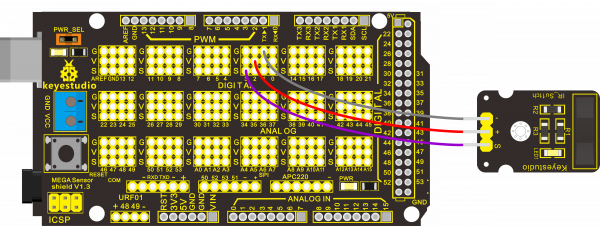

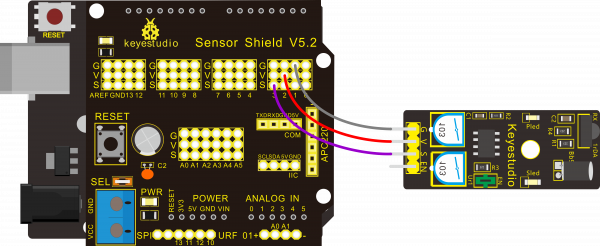

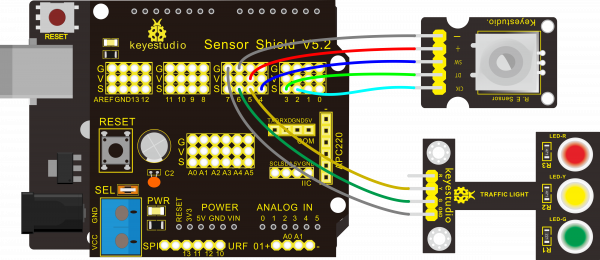

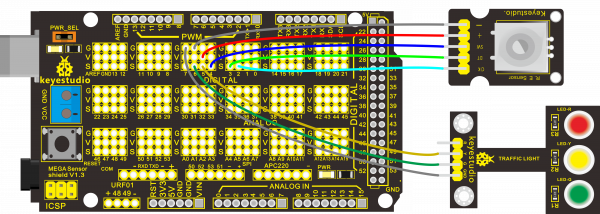

Connect the R pin of RGB module to Digital 10 of V4.0 board, connect the B pin to Digital 9, G pin to Digital 11, GND pin to ground port.

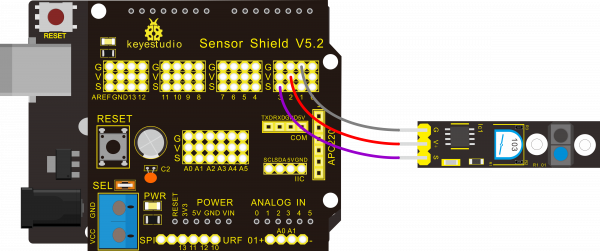

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

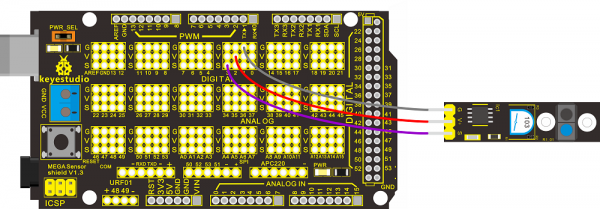

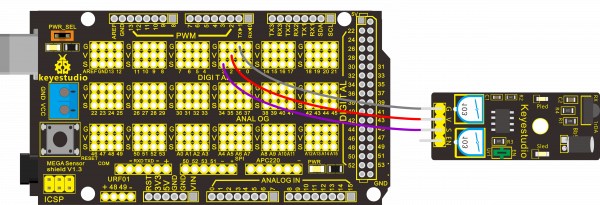

For 2560 R3 connection:

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

int redpin = 10; //select the pin for the red LED

int bluepin =9; // select the pin for the blue LED

int greenpin =11;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

}

void loop()

{for(val=255; val>0; val--)

{analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val<255; val++)

{analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

}

Experiment Result

You can see the RGB LED flashing in various colors.

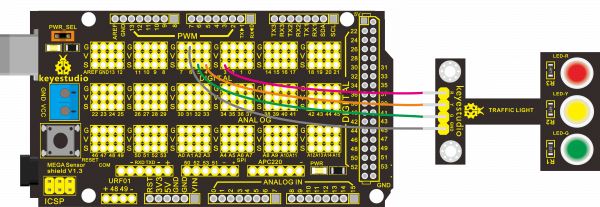

Project 3: Traffic Light

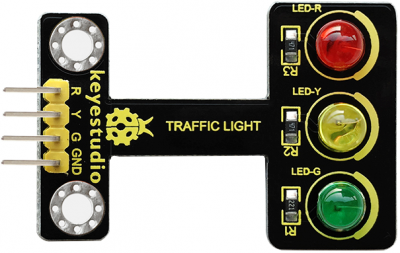

Description

When learning the microcontroller, you may usually use three LEDs, namely red, green and yellow lights to simulate the traffic light blinking via external connection.

This time we specially design this module which is very convenient for wiring, and on the module you can see the red, yellow and green LED.

This traffic light module is fully compatible with Arduino microcontroller and Raspberry Pi system.

Specifications

- Working Voltage: 3.3-5V

- Interface Type: digital

- Pin Pitch: 2.54mm

Hardware Connection

First, you need to prepare the following parts before connection:

- Arduino Board*1

- keyestudio Sensor Shield V5* 1

- Traffic light module *1

- USB Cable*1

- Jumper Wire*4

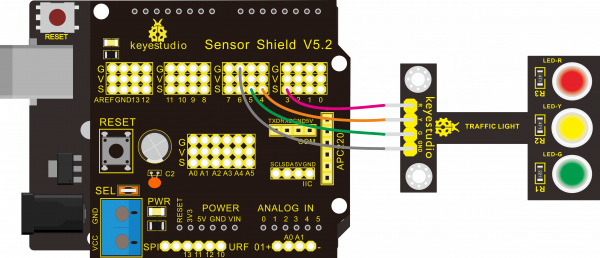

Connect the R pin of module to Digital 3 of V4.0 board, connect the Y pin to Digital 4, G pin to Digital 5, GND pin to ground port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

For 2560 R3 connection:

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

int redled =3; // initialize digital pin3.

int yellowled =4; // initialize digital pin 4.

int greenled =5; // initialize digital pin 5.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(greenled, OUTPUT); // set the pin with green LED as “output”

}

void loop()

{

digitalWrite(greenled, HIGH);//// turn on green LED

delay(5000);// wait 5 seconds

digitalWrite(greenled, LOW); // turn off green LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 seconds

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 seconds

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 seconds

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 seconds

digitalWrite(redled, LOW);// turn off red LED

}

Experiment Result

Done uploading the code, powered up, three LEDs on the module will automatically simulate the traffic light on and off, alternatively.

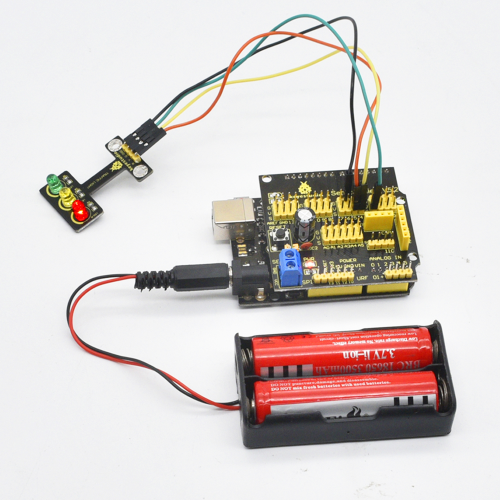

Project 4: Push Button

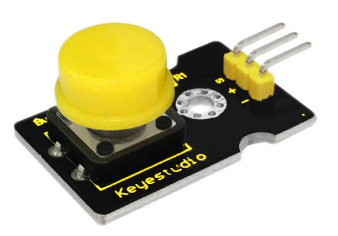

Introduction

This is a basic application module integrated with a push button. You can simply plug it into an IO shield to have your first taste of Arduino.

Advantages

- Wide voltage range from 3.3V to 5V

- Interface: Digital

- Standard assembling structure

- Icons illustrate sensor function clearly

- High quality pin

- Easy to plug and operate

- Large button keypad and high-quality button cap

- Achieve interesting and interactive work

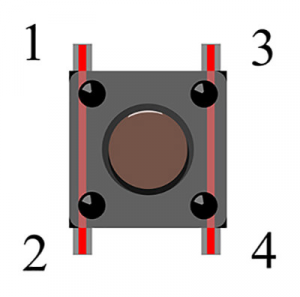

Components Introduction

Momentary Push button Switch:

This is a common component for controlling electronic devices. It is mostly used to connect or cut off control circuit so that it can achieve motor or other electronic equipment control.

Momentary Pushbutton Switch usually stays open. When it is pressed down, circuit connected; when it is released, it will bounce back to the status of disconnection.

Momentary Pushbutton Switch has 4 footers which can be divided into 2 groups: footer 1 short connected with footer 2, footer 3 short connected with footer 4.

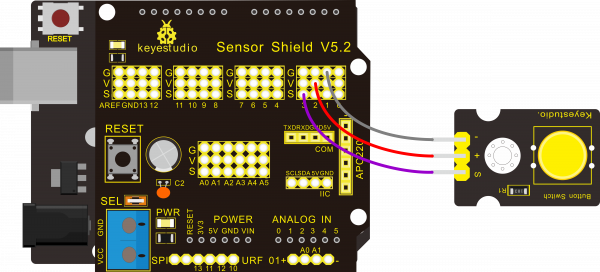

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Button module *1

- USB Cable *1

- Jumper Wire *3

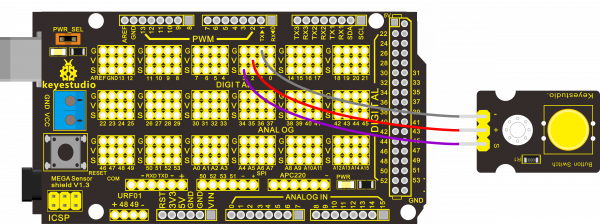

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

For 2560 R3 connection:

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

/* # When you push the digital button, the Led 13 will turn on. Otherwise, the led turns off.

*/

int ledPin = 13; // choose the pin for the LED

int inputPin = 3; // Connect sensor to input pin 3

void setup() {

pinMode(ledPin, OUTPUT); // declare LED as output

pinMode(inputPin, INPUT); // declare pushbutton as input

}

void loop(){

int val = digitalRead(inputPin); // read input value

if (val == HIGH) { // check if the input is HIGH

digitalWrite(ledPin, LOW); // turn LED OFF

} else {

digitalWrite(ledPin, HIGH); // turn LED ON

}

}

Experiment Result

Done uploading the code, powered up, when you push the digital button, the Led 13 on V4.0 board will be on. When release the button, the led is off. Shown as below.

Think:

If we want to connect more an LED module, light an LED when press down the button, and turn off LED when release the button, then how to program? You can have a try.

Project 5: Passive Buzzer

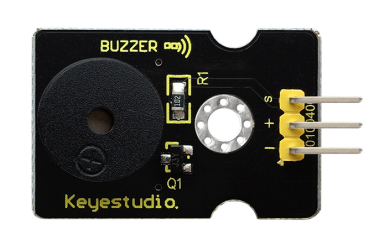

Introduction

We can use Arduino to make many interactive works of which the most commonly used is acoustic-optic display.

All the previous experiment has something to do with LED. However, the circuit in this experiment can produce sound. Normally, the experiment is done with a buzzer or a speaker while buzzer is simpler and easier to use.

The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequencies produce different sounds. We can use Arduino to code the melody of a song, which is quite fun and simple.

Specification

- Working voltage: 3.3-5v

- Interface type: digital

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Passive buzzer module *1

- USB Cable *1

- Jumper Wire *3

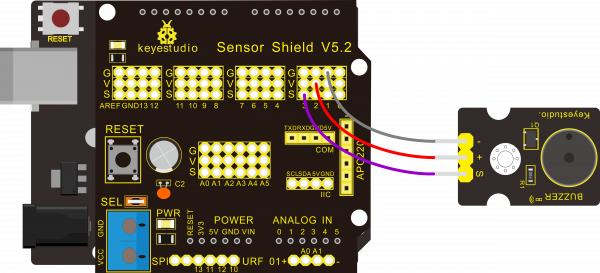

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

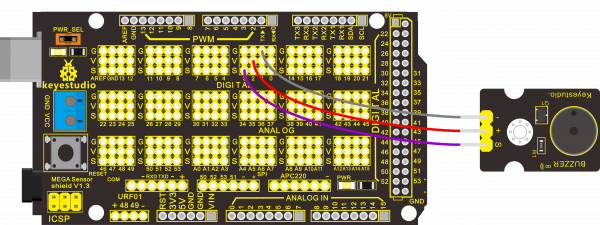

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

int buzzer=3;//set digital IO pin of the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output

}

void loop()

{ unsigned char i,j;//define variable

while(1)

{ for(i=0;i<80;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(1);//delay1ms

digitalWrite(buzzer,LOW);//not sound

delay(1);//ms delay

}

for(i=0;i<100;i++)// output a frequency sound

{

digitalWrite(buzzer,HIGH);// sound

digitalWrite(buzzer,LOW);//not sound

delay(2);//2ms delay

}

}

}

Experiment Result

After downloading the program, buzzer experiment is complete. You should hear the buzzer ringing.

Project 6: Capacitive Touch

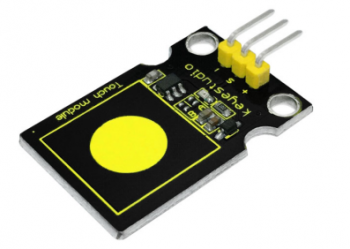

Introduction

Are you tired of clicking mechanic button? Well, try our capacitive touch sensor. We can find touch sensors mostly on electronic device. So upgrade your Arduino Project with our new version touch sensor and make it cool!!

This little sensor can "feel" people and metal touch and feedback a high/low voltage level. Even isolated by some cloth and paper, it can still feel the touch. Its sensitivity decrease as isolation layer gets thicker.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Digital

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Capacitive touch sensor module *1

- USB Cable *1

- Jumper Wire *3

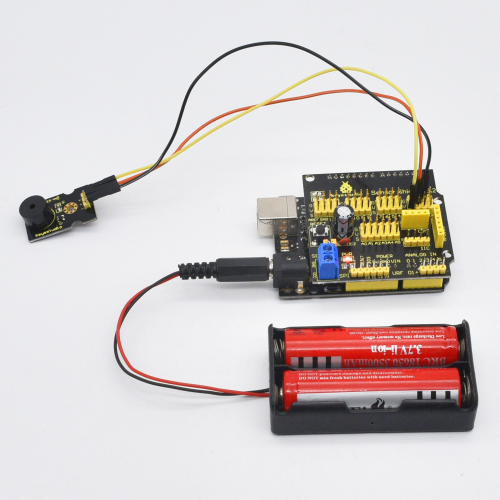

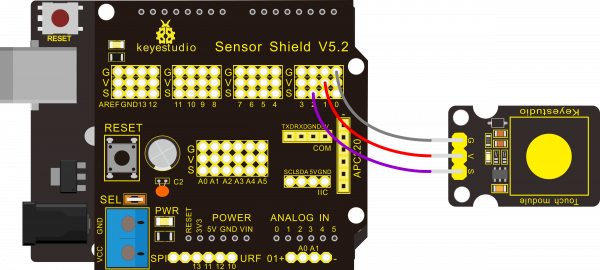

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

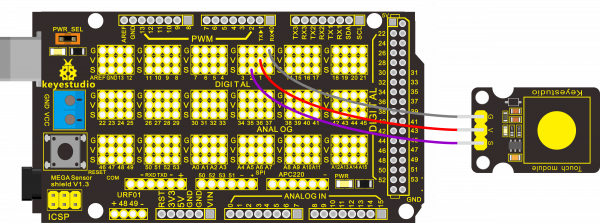

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

/* # When you push the digital button, the Led 13 will turn on. Otherwise, the led turns off.

*/

int ledPin = 13; // choose the pin for the LED

int inputPin = 3; // Connect sensor to input pin 3

void setup() {

pinMode(ledPin, OUTPUT); // declare LED as output

pinMode(inputPin, INPUT); // declare pushbutton as input

}

void loop(){

int val = digitalRead(inputPin); // read input value

if (val == HIGH) { // check if the input is HIGH

digitalWrite(ledPin, LOW); // turn LED OFF

} else {

digitalWrite(ledPin, HIGH); // turn LED ON

}

}

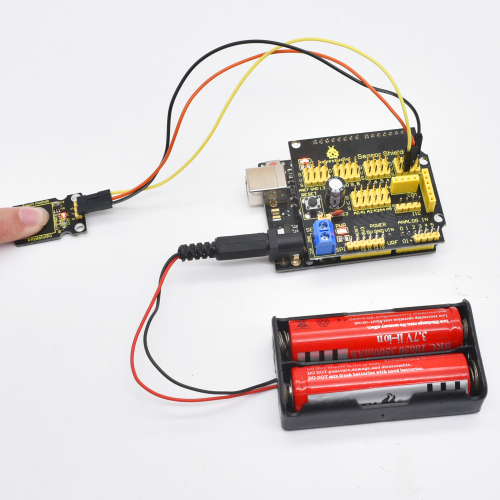

Experiment Result

Done uploading the code, powered up, when you push the digital button, the Led 13 on V4.0 board will be on. When release the button, the led is off. Shown as below.

Think:

If we want to connect more an LED module, light an LED when press down the button, and turn off LED when release the button, then how to program? You can have a try.

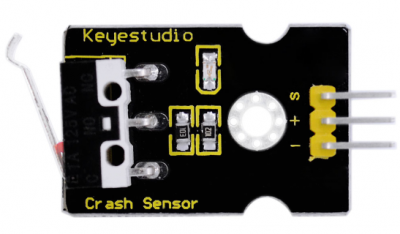

Project 7: Crash Sensor

Introduction

Crash sensor, also known as electronic switch, is a digital on-off input module necessary for elementary electronic learning. By programming, it can realize to control over light, sound device, key choice function of LCD display, etc.

You can install the sensor to 4WD mobile robot platform to realize crash detection function. It is indeed convenient and efficient.

Details

1. If collision happens upfront of where collision module is installed, module outputs low level signal; no collision, outputs high level signal.

2. Module reserves M3 mounting hole, convenient for fixation on a car.

4. With switch indicator light, if there is collision, light is on; no collision, light is off.

Pins definition

- Positive pin (+): connect to 3v-12v power supply

- Negative pin (-): connect to GND

- Signal pin (S): connect to High-Low level output

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Crash module *1

- USB Cable *1

- Jumper Wire *3

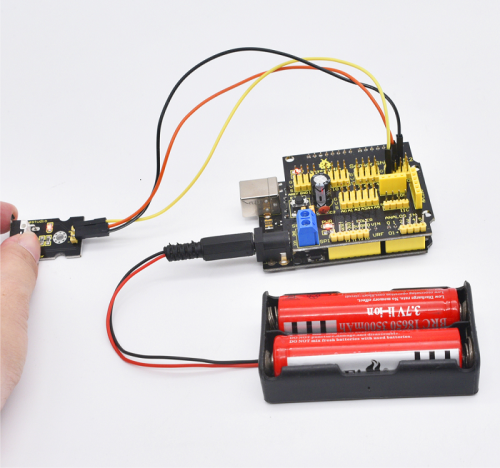

Note: You can make a collision flasher using collision module and built-in LED on interface 13. Connect the collision sensor to Digital pin 3. When the crash sensor senses a collision signal, the LEDs on both Arduino board and crash sensor will light up simultaneously.

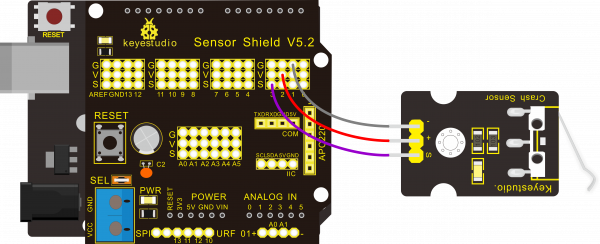

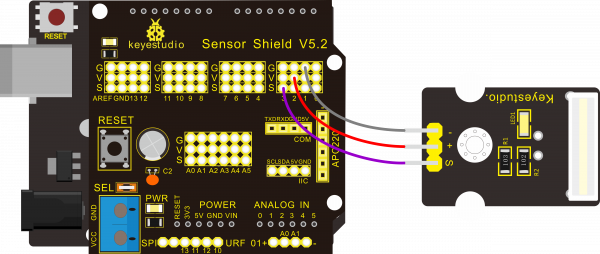

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

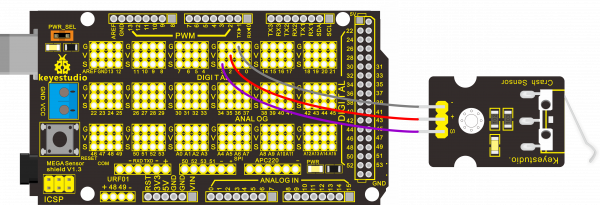

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

int Led=13;// set pin for LED

int Shock=3;// set pin for collision sensor

int val;// set digital variable val

void setup()

{

pinMode(Led,OUTPUT);// set pin LED as output

pinMode(Shock,INPUT);// set collision sensor as input

}

void loop()

{

val=digitalRead(Shock);// read value on pin 3 and assign it to val

if(val==HIGH)// when collision sensor detects a signal, LED turns on.

{

digitalWrite(Led,LOW);

} else

{

digitalWrite(Led,HIGH);

}

}

Experiment Result

Upload the code to the board.

When an object crashes the switch of sensor, both the led on the sensor and led 13 on the V4.0 board are turned on.

Project 8: Knock Sensor

Introduction

This is a knock sensor module. When you knock it, it can send a momentary signal. We can combine it with Arduino to make some interesting experiment, e.g. electronic drum.

Note: the working voltage of this module is 5V.

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Knock sensor module *1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

#define SensorLED 13

#define SensorINPUT 3 //Connect the sensor to digital Pin 3 which is Interrupts 1.

unsigned char state = 0;

void setup()

{

pinMode(SensorLED, OUTPUT);

pinMode(SensorINPUT, INPUT);

attachInterrupt(1, blink, FALLING);// Trigger the blink function when the falling edge is detected

}

void loop()

{ if(state!=0)

{

state = 0;

digitalWrite(SensorLED,HIGH);

delay(500);

}

else

digitalWrite(SensorLED,LOW);

}

void blink()//Interrupts function

{ state++;

}

Experiment Result

Upload the code to the board.

When the sensor detects a knock signal, both the led on the sensor and led 13 on the V4.0 board are turned on.

Think:

If not easy to see the test result, you can connect an external LED module. Light an LED when knock the sensor, then how to program? Think about it.

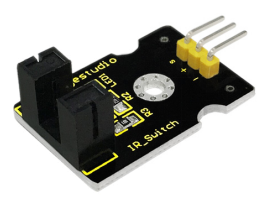

Project 9: Photo Interrupter

Introduction

Upright part of this sensor is an infrared emitter and on the other side, it’s a shielded infrared detector. By emitting a beam of infrared light from one end to other end, the sensor can detect an object when it passes through the beam.

It is used for many applications including optical limit switches, pellet dispensing, general object detection, etc.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Digital

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- Photo Interrupter module *1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

// photo interrupter module

int Led = 13 ;// define LED Interface

int buttonpin = 3; // define the photo interrupter sensor interface

int val ;// define numeric variables val

void setup ()

{

pinMode (Led, OUTPUT) ;// define LED as output interface

pinMode (buttonpin, INPUT) ;// define the photo interrupter sensor output interface

}

void loop ()

{

val = digitalRead (buttonpin) ;// digital interface will be assigned a value of 3 to read val

if (val == HIGH) // When the light sensor detects a signal is interrupted, LED flashes

{

digitalWrite (Led, HIGH);

}

else

{

digitalWrite (Led, LOW);

}

}

Experiment Result

Upload the code to the board. When an object passes through the groove joint of photo interrupter module, the signal is interrupted, led will flash.

Think:

If not easy to see the built-in led status, you can connect an external LED module, then how to program? Think about it.

Project 10: Digital Tilt Sensor

Introduction

Tilt Sensor is a simple digital tilt switch.

Simply plug it to our IO/Sensor shield or Arduino board, you can make interesting and interactive projects.

Tilt sensors (tilt ball switch) allow you to detect orientation or inclination. They are small, inexpensive, low-power and easy-to-use.

If used properly, they will not wear out. Their simplicity makes them popular for toys, gadgets and appliances.

Sometimes, they are referred to as "mercury switches", "tilt switches" or "rolling ball sensors" for obvious reasons.

They are usually made up of a cavity of some sort (cylindrical is popular, although not always) with a conductive free mass inside, such as a blob of mercury or rolling ball. One end of the cavity has two conductive elements (poles).

When the sensor is oriented so that that end is downwards, the mass rolls onto the poles and shorts them, acting as a switch throw.

While not as precise or flexible as a full accelerometer, tilt switches can detect motion or orientation. Another benefit is that the big ones can switch power on their own.

Accelerometer, on the other hand, output digital or analog voltage that must then be analyzed using extra circuitry.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Digital

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- Tilt ball switch module *1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

int ledPin = 13; // Connect LED to pin 13

int switcher = 3; // Connect Tilt sensor to Pin3

void setup()

{

pinMode(ledPin, OUTPUT); // Set digital pin 13 to output mode

pinMode(switcher, INPUT); // Set digital pin 3 to input mode

}

void loop()

{

if(digitalRead(switcher)==HIGH) //Read sensor value

{

digitalWrite(ledPin, HIGH); // Turn on LED when the sensor is tilted

}

else

{

digitalWrite(ledPin, LOW); // Turn off LED when the sensor is not triggered

}

}

Experiment Result

Upload the code to the board. Then tilt the sensor, you will see the led on the sensor is turned on. Shown as below.

Think:

Or you can connect more an external LED module, then how to program? Think about it. The LED will turn on when tilt the sensor, and the LED will turn off when the sensor is not tilted.

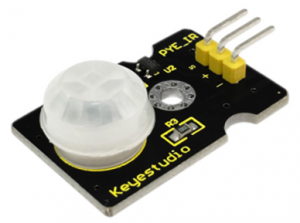

Project 11: PIR Motion Sensing

Introduction

Pyroelectric infrared motion sensor can detect infrared signals from a moving person or moving animal, and output switching signals.

It can be applied to a variety of occasions to detect the movement of human body.

Conventional pyroelectric infrared sensors require body pyroelectric infrared detector, professional chip, complex peripheral circuit, so the size is bigger, with complex circuit, and lower reliability.

Now we launch this new pyroelectric infrared motion sensor, specially designed for Arduino.

It uses an integrated digital body pyroelectric infrared sensor, has smaller size, higher reliability, lower power consumption and simple peripheral circuit.

Specification

- Input Voltage: 3.3 ~ 5V, 6V Maximum

- Working Current: 15uA

- Working Temperature: -20 ~ 85 ℃

- Output Voltage: High 3V, low 0V

- Detection angle: 100 °

- Detection distance: 7 meters

- Output Indicator LED (When output HIGH, it will be ON)

- Pin limit current: 100mA

Hardware Connection

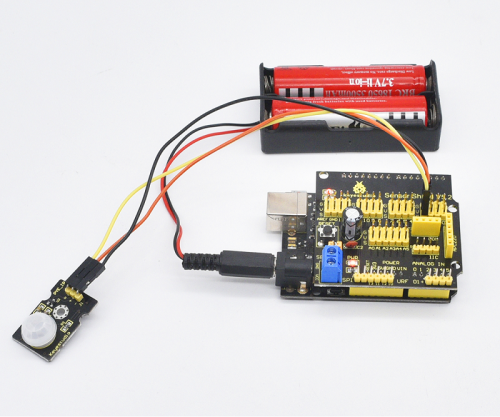

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- PIR motion sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

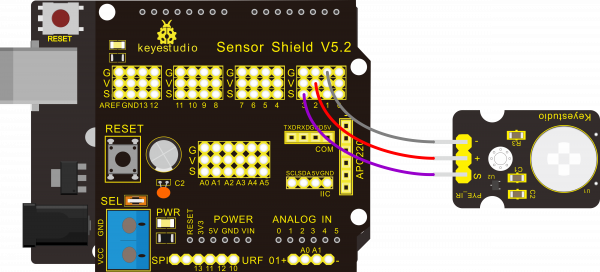

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

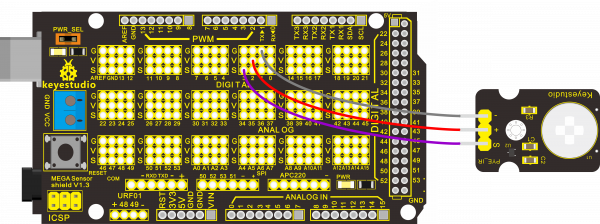

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

byte sensorPin = 3;

byte indicator = 13;

void setup()

{

pinMode(sensorPin,INPUT);

pinMode(indicator,OUTPUT);

Serial.begin(9600);

}

void loop()

{

byte state = digitalRead(sensorPin);

digitalWrite(indicator,state);

if(state == 1)Serial.println("Somebody is in this area!");

else if(state == 0)Serial.println("No one!");

delay(500);

}

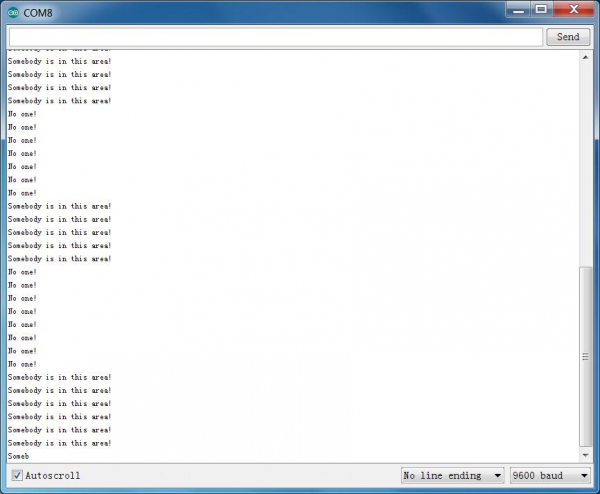

Experiment Result

Done wiring and powered up, upload well the code, if the sensor detects someone moving nearby, D13 indicator on V4.0 board will light up, and "Somebody is in this area!" is displayed on the serial monitor.

If no detecting the movement, D13 indicator will turn off, and "No one!" is displayed on the serial monitor.

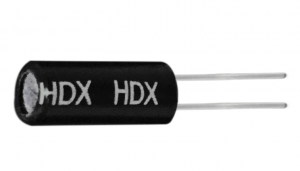

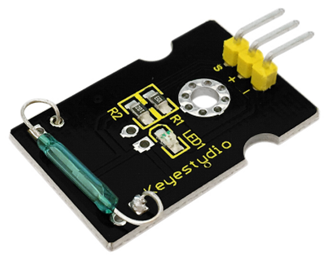

Project 12: Reed Switch

Description

Reed Switch is a special switch and a main component for reed relay and proximity switch. Reed switch is usually comprised of two soft magnetic materials and metal reed contacts which will disconnect itself when there is no magnetic.

In addition, some reed switches are also equipped with another reed acting as the third normally-closed contact. These reed contacts are encapsulated in a glass tube fulled of inert gases(such as nitrogen and helium) or in a vacuum glass tube.

The reeds encapsulated in the glass tube are placed in parallel with ends overlapped. Certain amount of space or mutual contact will be reserved to constitute the normally-open or normally-closed contacts of the switch.

Reed switch can be used as for count, limit or other purposes. For instance, a kind of bike-kilometer is constituted by sticking magnetic to the tire and mounting reed switch aside. You can also mount reed switch on the door for alarming purpose or as switches.

Reed switch has been widely applied in household appliances, cars, communication, industry, healthcare and security areas.

Furthermore, it can also be applied to other sensors and electric devices such as liquidometer, door magnet, reed relay, oil level sensor and proximity sensor(magnetic sensor). It can be used under high-risk environment.

Specification

- Working voltage: DC 3.3V-5V

- Working current: ≥20mA

- Working temperature: -10℃ to+50℃

- Detection distance: ≤10mm

- IO Interface: 3Pin (-/+/S)

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5 * 1

- Reed switch sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

Copy and paste the below code to Arduino software.

int Led=13;//define LED interface

int buttonpin=3; //define magnetic ring sensor interface

int val;//define digital variable val

void setup()

{

pinMode(Led,OUTPUT);//define LED as output interface

pinMode(buttonpin,INPUT);//define magnetic ring sensor as output interface

}

void loop()

{

val=digitalRead(buttonpin);// read and assign the value of digital interface 3 to val

if(val==HIGH)//When a signal is detected by magnetic ring sensor, LED will flash

{

digitalWrite(Led,HIGH);

}

else

{

digitalWrite(Led,LOW);

}

}

Experiment Result

Done wiring and powered up, upload well the code to the board. You can see the D13 led on V4.0 board is on.

Then we put some magnetic balls close to the sensor. When the sensor detects the magnetic field signal, the led on the sensor will be turned on but D13 led will be turned off.

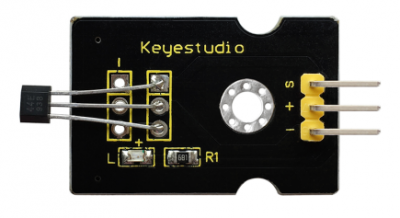

Project 13: Hall Magnetic Sensor

Introduction

This is a Magnetic Induction Sensor. It senses the magnetic materials within a detection range up to 3cm.

The detection range and the strength of the magnetic field are proportional.

The output is digital on/off. This sensor uses the SFE Reed Switch - Magnetic Field Sensor.

Specification

- Sensing magnetic materials

- Detection range: up to 3cm

- Output: digital on/off

- Detection range and magnetic field strength are proportional

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5 * 1

- Hall Magnetic sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

int ledPin = 13; // choose the pin for the LED

int inputPin = 3; // Connect sensor to input pin 3

int val = 0; // variable for reading the pin status

void setup() {

pinMode(ledPin, OUTPUT); // declare LED as output

pinMode(inputPin, INPUT); // declare pushbutton as input

}

void loop(){

val = digitalRead(inputPin); // read input value

if (val == HIGH) { // check if the input is HIGH

digitalWrite(ledPin, LOW); // turn LED OFF

} else {

digitalWrite(ledPin, HIGH); // turn LED ON

}

}

Experiment Result

Wire it up and upload well the code to board, you will see that D13 indicator on V4.0 board is off, and led on the module is also off.

But if put a magnetic ball close to the hall module, you will see the D13 indicator on V4.0 board is turned on, and led on the module is also turned on.

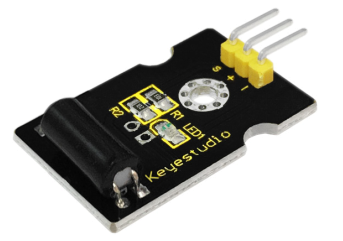

Project 14: Line Tracking

Introduction

This Line Tracking Sensor can detect white line in black and black line in white. The single line-tracking signal provides a stable output signal TTL for a more accurate and more stable line. Multi-channel option can be easily achieved by installing required line-tracking robot sensors.

Specification

- Power supply: +5V

- Operating current: <10mA

- Operating temperature range: 0°C ~ + 50°C

- Output interface: 3Pin interface (1 - signal, 2 - power, 3 - power supply negative)

- Output Level: TTL level

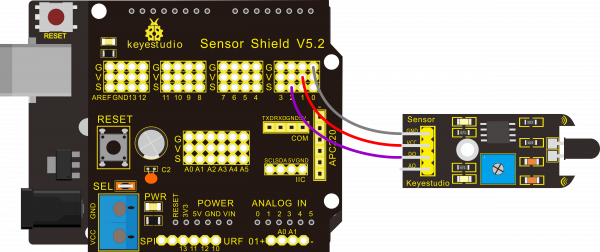

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Line tracking sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

///Arduino Sample Code

void setup()

{

Serial.begin(9600);

}

void loop()

{

Serial.println(digitalRead(3)); // print the data from the sensor

delay(500);

}

Experiment Result

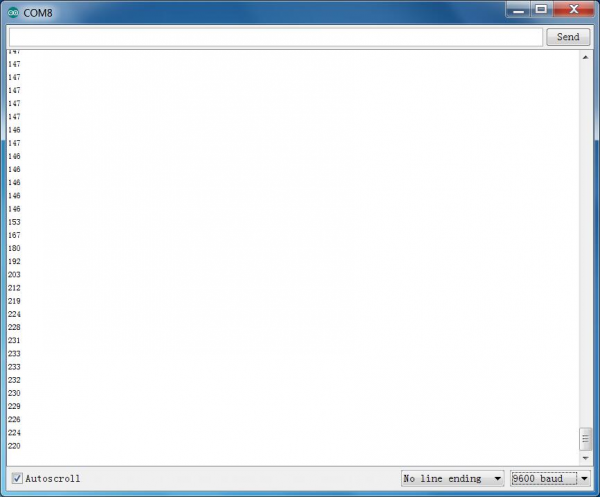

Done uploading the code to board, open the serial monitor and set the baud rate to 9600, then you can see the data from the sensor. Shown below.

Project 15: Flame Sensor

Introduction

This flame sensor can be used to detect fire or other lights whose wavelength stands at 760nm ~ 1100nm. In the fire-fighting robot game, the flame plays an important role in the probe, which can be used as the robot's eyes to find fire source.

Specification

- Supply Voltage: 3.3V to 5V

- Detection range: 20cm (4.8V) ~ 100cm (1V)

- Rang of Spectral Bandwidth: 760nm to 1100nm

- Operating temperature: -25℃ to 85℃

- Interface: digital

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Flame sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 2, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

const int flamePin = 2; // the number of the flame pin

const int ledPin = 13; // the number of the LED pin

// variables will change:

int State = 0; // variable for reading status

void setup() {

// initialize the LED pin as an output:

pinMode(ledPin, OUTPUT);

// initialize the pushbutton pin as an input:

pinMode(flamePin, INPUT);

}

void loop(){

// read the state of the value:

State = digitalRead(flamePin);

if (State == HIGH) {

// turn LED on:

digitalWrite(ledPin, HIGH);

}

else {

// turn LED off:

digitalWrite(ledPin, LOW);

}

}

Experiment Result

Done wiring and powered up, upload well the code to the board.

Then if you put a lighter close to the sensor, when the sensor detects the flame, another led on the sensor is turned on.

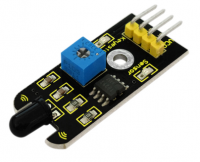

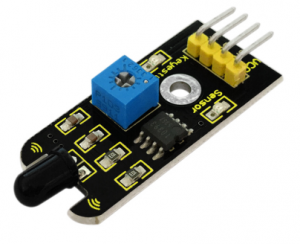

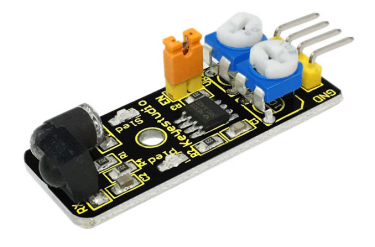

Project 16: Infrared Obstacle Avoidance

Introduction

Infrared obstacle avoidance sensor is equipped with distance adjustment function and is especially designed for wheeled robots.

This sensor has strong adaptability to ambient light and is of high precision. It has a pair of infrared transmitting and receiving tube.

When infrared ray launched by the transmitting tube encounters an obstacle (its reflector), the infrared ray is reflected to the receiving tube, and the indicator will light up; the signal output interface outputs digital signal.

We can adjust the detection distance through the potentiometer knob (effective distance: 2~40cm, working Voltage: 3.3V-5V ).

Thanks to a wide voltage range, this sensor can work steadily even under fluctuating power supply voltage and is suitable for the use of various micro-controllers, Arduino controllers and BS2 controllers.

A robot mounted with the sensor can sense changes in the environment.

Specification

- Working voltage: DC 3.3V-5V

- Working current: ≥20mA

- Working temperature: -10℃—+50℃

- Detection distance: 2-40cm

- IO Interface: 4 wire interface (-/+/S/EN)

- Output signal: TTL voltage

- Accommodation mode: Multi-circle resistance regulation

- Effective Angle: 35°

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Infrared obstacle avoidance sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board

Sample Code

const int sensorPin = 3; // the number of the sensor pin

const int ledPin = 13; // the number of the LED pin

int sensorState = 0; // variable for reading the sensor status

void setup() {

pinMode(ledPin, OUTPUT);

pinMode(sensorPin, INPUT); }

void loop(){

// read the state of the sensor value:

sensorState = digitalRead(sensorPin);

// if it is, the sensorState is HIGH:

if (sensorState == HIGH) {

digitalWrite(ledPin, HIGH);

}

else {

digitalWrite(ledPin, LOW);

}

}

Experiment Result

Done uploading the code to board, if we put a foam block in front of the sensor, this time when sensor detects the obstacle, sled on the sensor will be turned on.

Project 17 : Photocell sensor

Introduction

Photocell is commonly seen in our daily life and is mainly used in intelligent switch, also in common electronic design. To make it easier and more effective, we supply corresponding modules.

Photocell is a semiconductor. It has features of high sensitivity, quick response, spectral characteristic, and R-value consistence, maintaining high stability and reliability in environment extremes such as high temperature, high humidity.

It’s widely used in automatic control switch fields like cameras, garden solar lights, lawn lamps, money detectors, quartz clocks, music cups, gift boxes, mini night lights, sound and light control switches, etc.

Specification

- Interface type: analog

- Working voltage: 5V

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Photocell sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

int sensorPin =A0 ;

int value = 0;

void setup()

{

Serial.begin(9600); }

void loop()

{

value = analogRead(sensorPin);

Serial.println(value, DEC);

delay(50); }

Experiment Result

Done wiring and powered up, upload well the code, then open the serial monitor; if cover the photocell on the sensor with your hand, you will see the analog value decrease.

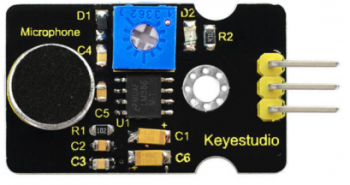

Project 18: Analog Sound Sensor

Introduction

Analog Sound Sensor is typically used in detecting the loudness in ambient environment. The Arduino can collect its output signal by imitating the input interface. The sensor comes with a potentiometer, so that you can adjust the sensitivity. You can use it to make some interesting interactive works, such as a voice operated switch.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Analog

- Detecting sound intensity

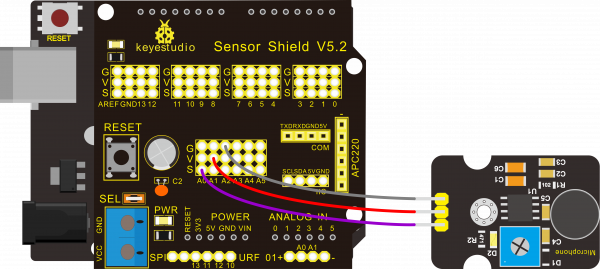

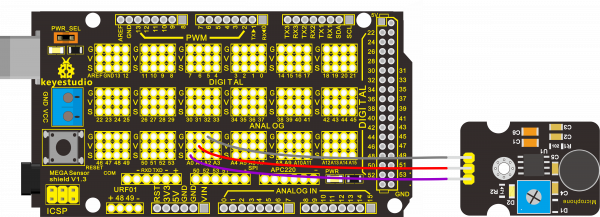

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- Sound sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

void setup()

{

Serial.begin(9600); // open serial port, set the baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0); //connect mic sensor to Analog 0

Serial.println(val,DEC);//print the sound value to serial

delay(100);

}

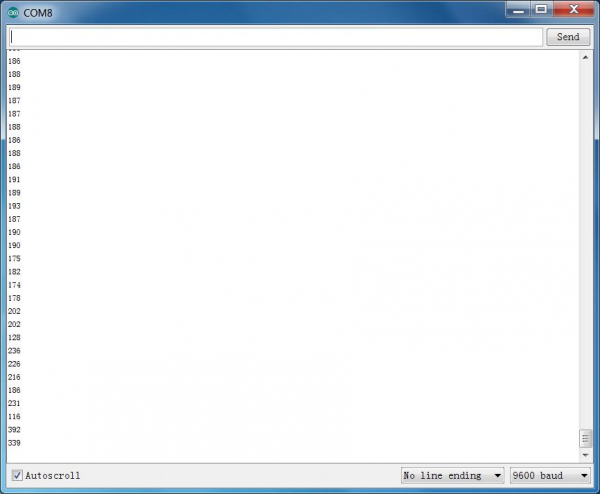

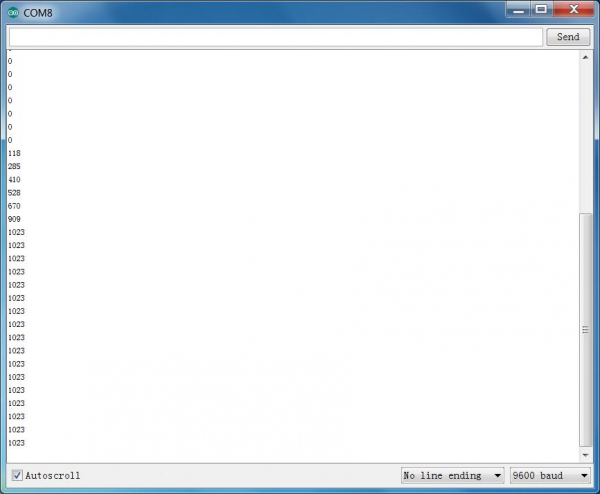

Experiment Result

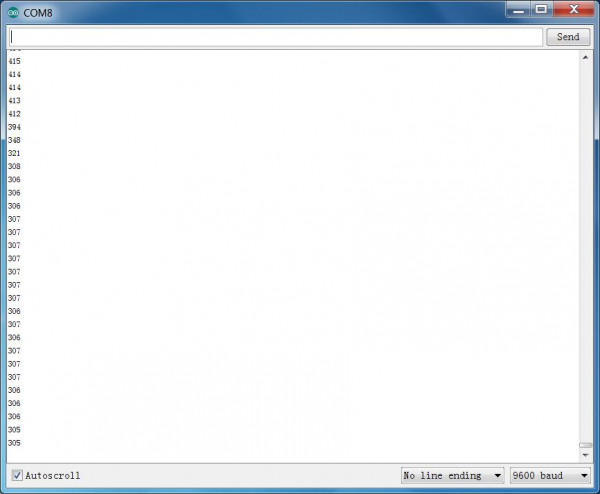

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate to 9600, you will see the analog value.

When talking toward the micro head, the value will increase. Shown below.

You can the potentiometer to adjust the sensitivity.

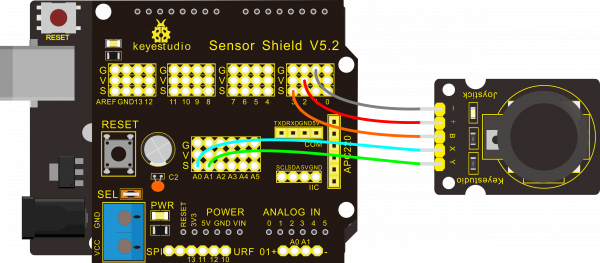

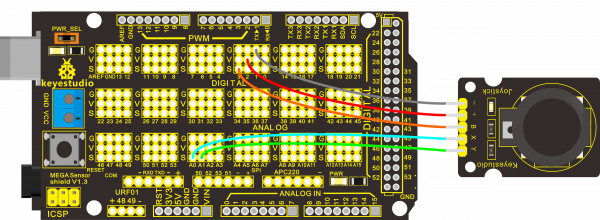

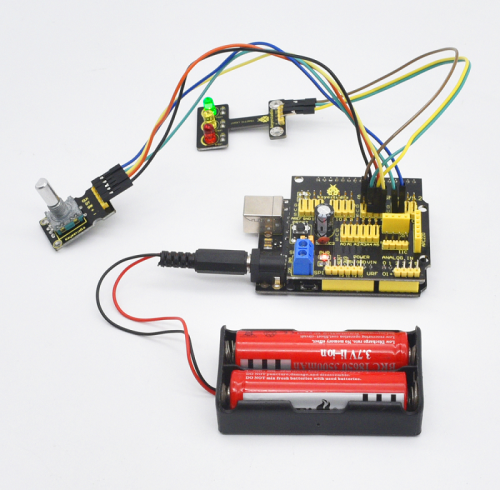

Project 19: Rotary Encoder

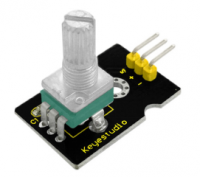

Introduction

The rotary encoder can count the pulse outputting times during the process of its rotation in positive and reverse direction by rotating. This rotating counting is unlimited, not like potential counting. It can be restored to initial state to count from 0 with the button on rotary encoder.

Combined with other sensors, we can make interesting projects by reading the analog value from the IO port.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Analog

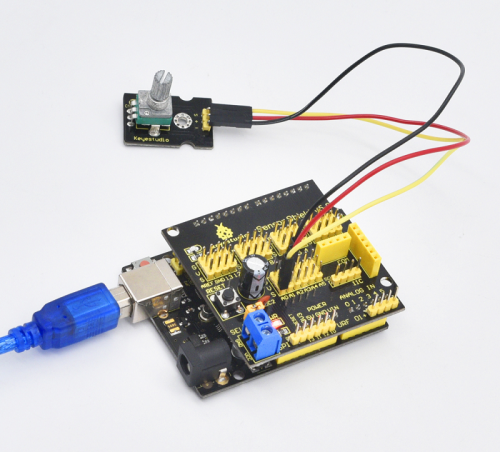

Hardware Connection

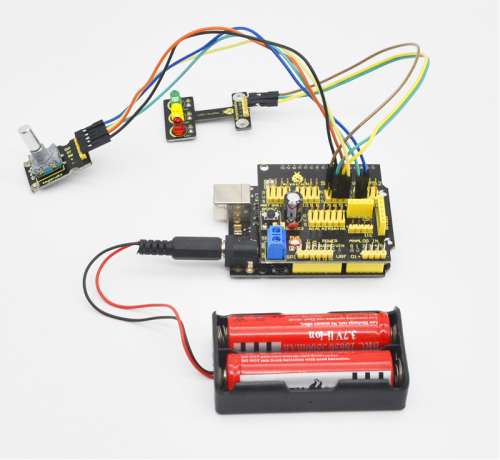

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Rotary encoder sensor*1

- traffic light module *1

- USB Cable *1

- Jumper Wire *3

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection:

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

const int interruptA = 0;

const int interruptB = 1;

int CLK = 2; // PIN2

int DAT = 3; // PIN3

int BUTTON = 4; // PIN4

int LED1 = 5; // PIN5

int LED2 = 6; // PIN6

int COUNT = 0;

void setup()

{

attachInterrupt(interruptA, RoteStateChanged, FALLING);

// attachInterrupt(interruptB, buttonState, FALLING);

pinMode(CLK, INPUT);

digitalWrite(2, HIGH); // Pull High Restance

pinMode(DAT, INPUT);

digitalWrite(3, HIGH); // Pull High Restance

pinMode(BUTTON, INPUT);

digitalWrite(4, HIGH); // Pull High Restance

pinMode(LED1, OUTPUT);

pinMode(LED2, OUTPUT);

Serial.begin(9600);

}

void loop()

{

if (!(digitalRead(BUTTON)))

{

COUNT = 0;

Serial.println("STOP COUNT = 0");

digitalWrite(LED1, LOW);

digitalWrite(LED2, LOW);

delay (2000);

}

Serial.println(COUNT);

}

//-------------------------------------------

void RoteStateChanged() //When CLK FALLING READ DAT

{

if (digitalRead(DAT)) // When DAT = HIGH IS FORWARD

{

COUNT++;

digitalWrite(LED1, HIGH);

digitalWrite(LED2, LOW);

delay(20);

}

else // When DAT = LOW IS BackRote

{

COUNT--;

digitalWrite(LED2, HIGH);

digitalWrite(LED1, LOW);

delay(20);

}

}

Experiment Result

Wiring well and uploading the above code, you can rotate the encoder module to randomly control two LED modules on and off.

When you rotate the encoder module, one LED module is turned on first but another one is off. If you continue to rotate the encoder module, one LED module becomes off while another one is turned on, repeatedly.

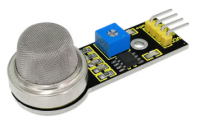

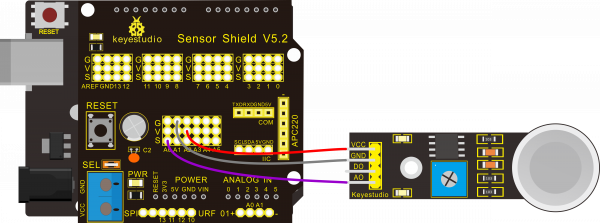

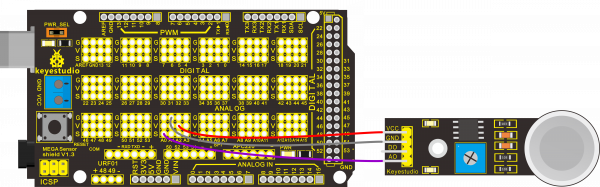

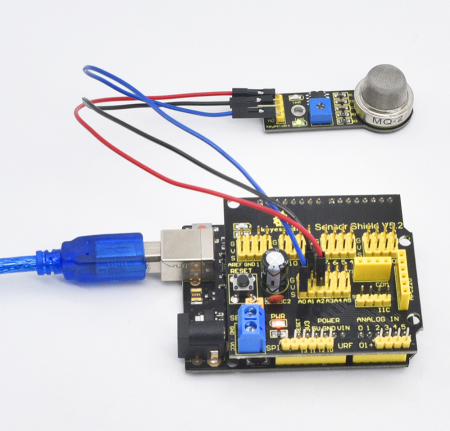

Project 20: Analog Gas Sensor

Introduction

This analog gas sensor - MQ2 is used in gas leakage detecting equipment in consumer electronics and industrial markets.

This sensor is suitable for detecting LPG, I-butane, propane, methane, alcohol, Hydrogen and smoke. It has high sensitivity and quick response.

In addition, the sensitivity can be adjusted by the potentiometer.

Specification

- Power supply: 5V

- Interface type: Analog

- Wide detecting scope

- Quick response and High sensitivity

- Simple drive circuit

- Stable and long lifespan

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- Analog gas sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection:

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

///Arduino Sample Code

void setup()

{

Serial.begin(9600); //Set serial baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0);//Read Gas value from analog 0

Serial.println(val,DEC);//Print the value to serial port

delay(100);

}

Experiment Result

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 9600, you will see the analog value.

When detecting the gas, the value will make a change.

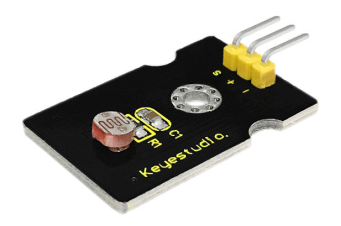

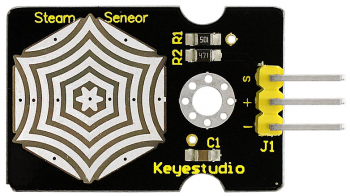

Project 21: Steam Moisture

Introduction

Vapor Sensor is an analog sensor and can make a simple rainwater detector and liquid level switch. When humidity on the face of this sensor rises, output voltage will increase.

Caution: connection parts is non-waterproof, so please don’t put them into water.

Specification

- Working Voltage: 3.3V or 5V

- Working Current: <20mA

- Range of Working Temperature: -10℃~+70℃

- Interface Type: Analog Signal Output

Pins Definition

- S pin: for Signal Output

- Positive pin (+): for Power Supply (VCC)

- Negative pin (-): for Ground (GND)

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- Steam sensor*1

- USB Cable *1

- Jumper Wire *3

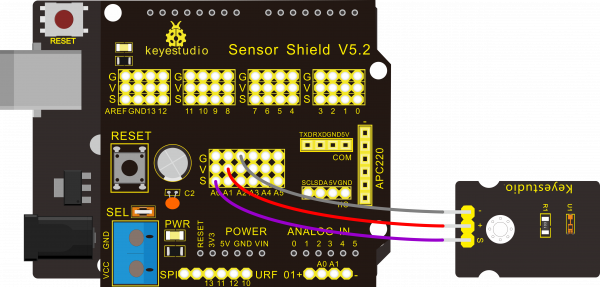

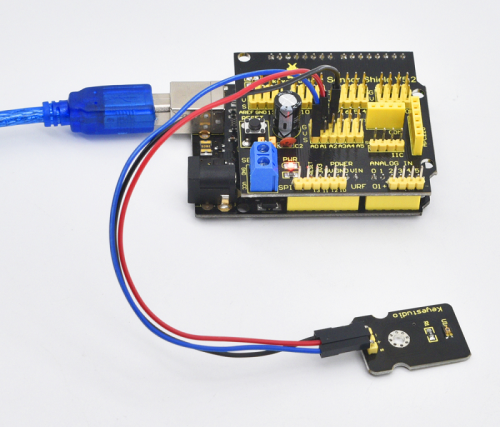

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

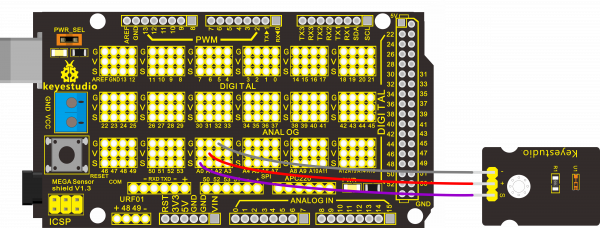

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

void setup()

{

Serial.begin(9600); //open serial port, and set baud rate at 9600bps

}

void loop()

{

int val;

val=analogRead(0); //plug vapor sensor into analog port 0

Serial.print("Moisture is ");

Serial.println(val,DEC); //read analog value through serial port printed

delay(100);

}

Experiment Result

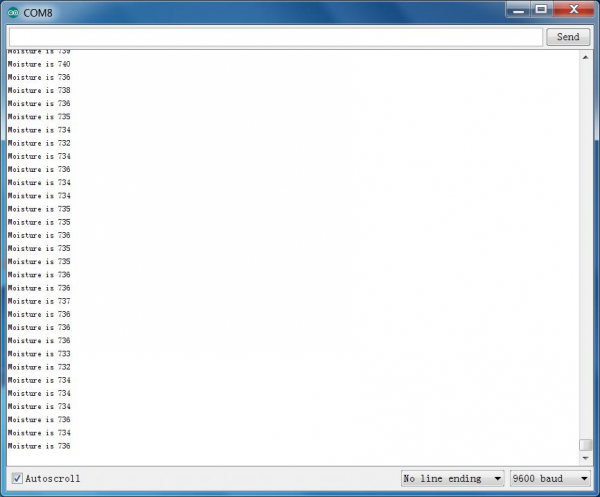

When detecting different degrees of humidity, the sensor will get the feedback of different current value. Shown as the following picture.

Due to the limited condition, you can put a drop of water on the sensor, the moisture value will be changed on serial monitor of Arduino software.

Project 22: TEMT6000 Ambient Light

Introduction

At some point you are going to want to sense ambient brightness with better precision than your trusty photoresistor without adding complexity to your project. When that day comes, go get yourself a TEMT6000 ambient light sensor.

The TEMT6000 is supposed to be adapted to the sensitivity of the human eye, but I found it preformed sub-par in low light conditions. It does however work very well reacting to very small changes in a large range of brightness. Because it is meant to mimic the human eye, it does not react well to IR or UV light, so just make sure to note that when considering using it in your project.

Hooking It Up

This is an incredibly simple part, just connect power and ground, and the signal pin to your favorite analog input and you are done, the sensor will output analog voltage, that ramps up when it gets brighter. You can power this off of 3.3v if you would like, the output value will just be lower.

Firstly you need to prepare the following parts before connection.

- Arduino Board*1

- keyestudio Sensor Shield V5* 1

- TEMT6000 ambient light sensor*1

- USB Cable*1

- Jumper Wire*3

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

You can not get more simple than this – This just reports the reading from the sensor to the serial terminal: 0-1023 with 1023 being very bright, and 0 being very dark.

int temt6000Pin = 0;

void setup() {

Serial.begin(9600);

}

void loop() {

int value = analogRead(temt6000Pin);

Serial.println(value);

delay(100); //only here to slow down the output so it is easier to read

}

Experiment Result

Wiring well and uploading the code above, open the serial monitor.

Then cover the sensor with your hand or a paper, the light becomes weak, finally you will see the value showed on monitor decrease.

Project 23: LM35 Linear Temperature

Introduction

LM35 Linear Temperature Sensor is based on semiconductor LM35 temperature sensor. It can be used to detect ambient air temperature. This sensor offers a functional range among 0 degree Celsius to 100 degree Celsius. Sensitivity is 10mV per degree Celsius. The output voltage is proportional to the temperature.

This sensor is commonly used as a temperature measurement sensor. It includes thermocouples, platinum resistance, thermal resistance and temperature semiconductor chips. The chip is commonly used in high temperature measurement thermocouples. Platinum resistance temperature sensor is used in the measurement of 800 degrees Celsius, while the thermal resistance and semiconductor temperature sensor is suitable for measuring the temperature of 100-200 degrees or below, in which the application of a simple semiconductor temperature sensor is good in linearity and high in sensitivity.

The LM35 linear temperature sensor is easily connected to Arduino shield.

Specification

- Based on the semiconductor LM35 temperature sensor

- Can be used to detect ambient air temperature

- Sensitivity: 10mV per degree Celcius

- Functional range: 0 degree Celsius to 100 degree Celsius

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- LM35 temperature sensor*1

- USB Cable *1

- Jumper Wire *3

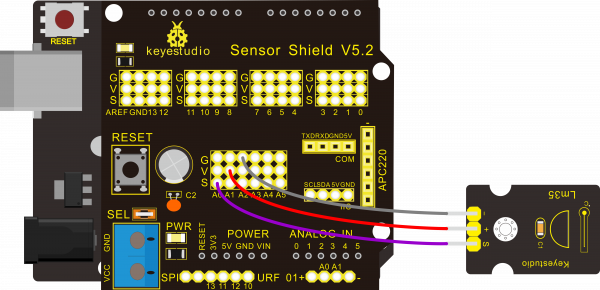

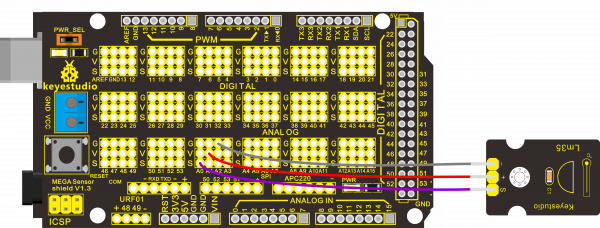

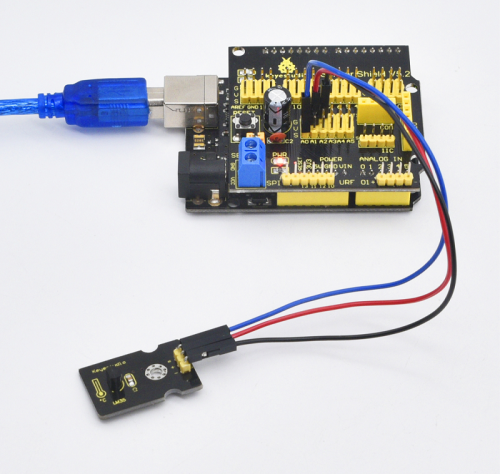

Connect the S pin to analog A0, negative pin to GND port, positive pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

void setup()

{

Serial.begin(9600);//Set Baud Rate to 9600 bps

}

void loop()

{ int val;

int dat;

val=analogRead(0);//Connect LM35 on Analog 0

dat=(500 * val) /1024;;

Serial.print("Temp:"); //Display the temperature on Serial monitor

Serial.print(dat);

Serial.println("C");

delay(500);

}

Experiment Result

Upload well the code to the board, then open the serial monitor and set the baud rate to 9600, finally you will see the current temperature value shown below. The value may be slight difference due to different places and weather.

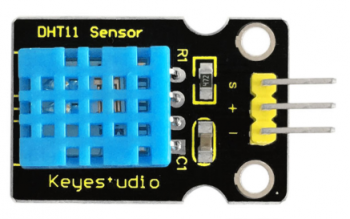

Project 24: DHT11 Temperature and Humidity

Introduction

This DHT11 sensor features calibrated digital signal output with the temperature and humidity sensor complex. Its technology ensures high reliability and excellent long-term stability. A high-performance 8-bit microcontroller is connected.

This sensor includes a resistive element and a sense of wet NTC temperature measuring devices. It has excellent quality, fast response, anti-interference ability and high cost performance advantages.

Each DHT11 sensor features extremely accurate calibration data of humidity calibration chamber. The calibration coefficients stored in the OTP program memory, internal sensors detect signals in the process, and we should call these calibration coefficients.

The single-wire serial interface system is integrated to make it quick and easy. Qualities of small size, low power, and 20-meter signal transmission distance make it a wide applied application and even the most demanding one. Convenient connection, special packages can be provided according to users need.

Specification

- Supply Voltage: +5 V

- Temperature range: 0-50 °C error of ± 2 °C

- Interface: Digital

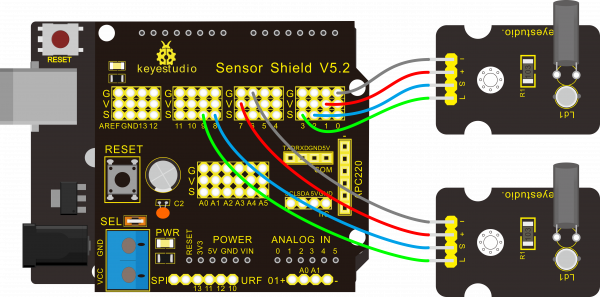

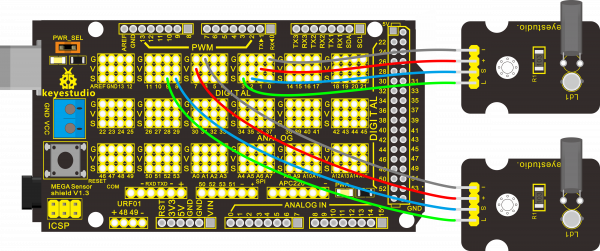

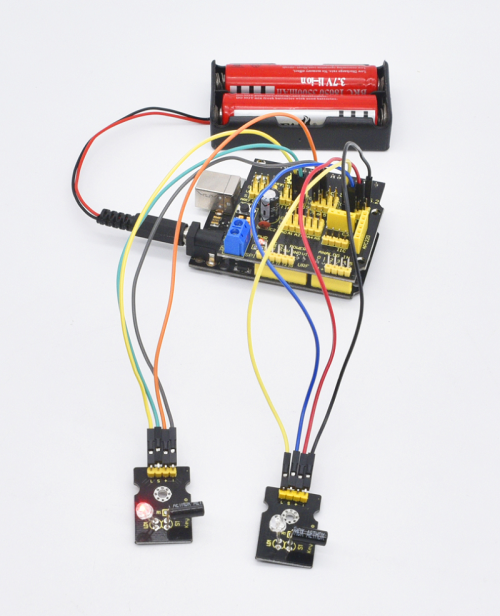

Hardware Connection

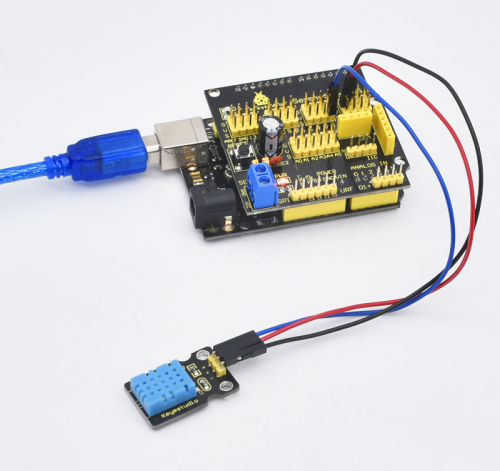

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- DHT11 Temperature and Humidity Sensor*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital D4, negative pin to GND port, positive pin to 5V port.

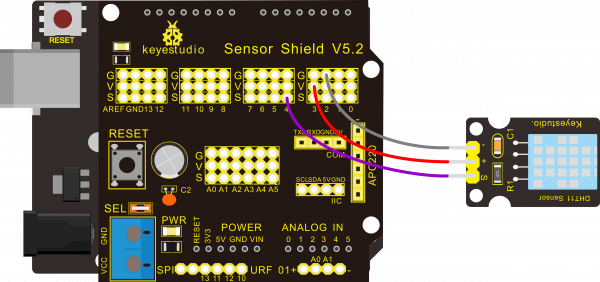

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

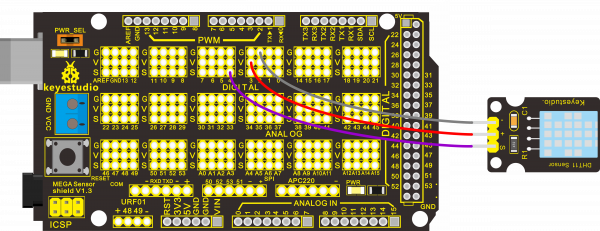

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

Please download the DHT11Lib firstly.Or,see the website

#include <dht11.h>

dht11 DHT;

#define DHT11_PIN 4

void setup(){

Serial.begin(9600);

Serial.println("DHT TEST PROGRAM ");

Serial.print("LIBRARY VERSION: ");

Serial.println(DHT11LIB_VERSION);

Serial.println();

Serial.println("Type,\tstatus,\tHumidity (%),\tTemperature (C)");

}

void loop(){

int chk;

Serial.print("DHT11, \t");

chk = DHT.read(DHT11_PIN); // READ DATA

switch (chk){

case DHTLIB_OK:

Serial.print("OK,\t");

break;

case DHTLIB_ERROR_CHECKSUM:

Serial.print("Checksum error,\t");

break;

case DHTLIB_ERROR_TIMEOUT:

Serial.print("Time out error,\t");

break;

default:

Serial.print("Unknown error,\t");

break;

}

// DISPLAT DATA

Serial.print(DHT.humidity,1);

Serial.print(",\t");

Serial.println(DHT.temperature,1);

delay(1000);

}

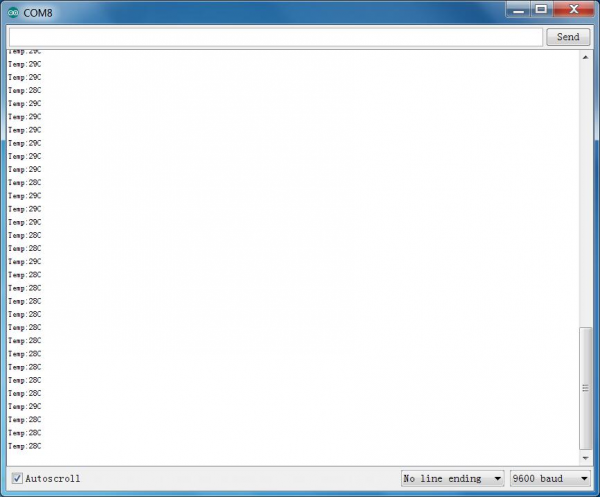

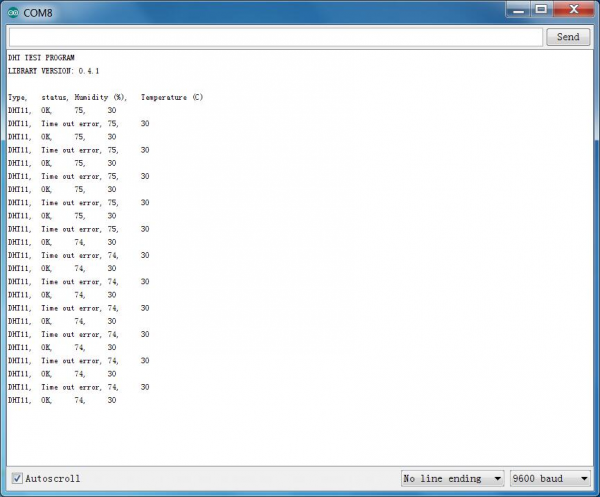

Experiment Result

Wire it up well and upload the above code to V4.0 board.

Then open the serial monitor and set the baud rate to 9600, you will see the current temperature and humidity value.

Project 25: Magical Light Cup

Introduction

Magic light cup module is able to interact with ARDUINO. The principle is based on PWM dimming. The mercury switch on the module can provide a digital signal and trigger PWM regulation. The brightness of two modules will be changed together through the program design, finally you can see the changing effect that two set of cups are pouring the light.

Specification

- Supply Voltage: 3.3V to 5V

- Interface: Digital

Connection Diagram

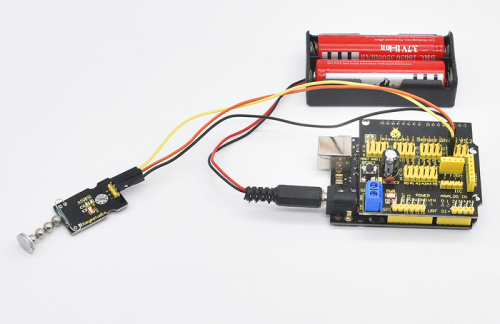

Firstly you need to prepare the following parts.

- Arduino Board*1

- Light cap module*2

- USB Cable*1

- Breadboard *1

- Jumper Wire*10

For one light cap module, connect its Signal pin to Digital header 2, L pin to Digital pin 3. For another one, connect its Signal pin to Digital port 8, L pin to Digital 9.

Connect the positive pin to anode row of breadboard, lead off the row to 5V port of V4.0 board; connect the negative pin to cathode row, lead off the row to ground port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

Copy and paste the code below to Arduino software.

int LedPinA = 3;

int LedPinB = 9;

int ButtonPinA =2;

int ButtonPinB = 8;

int buttonStateA = 0;

int buttonStateB = 0;

int brightnessA = 0;

int brightnessB= 255;

void setup()

{

Serial.begin(9600);

pinMode(LedPinA, OUTPUT);

pinMode(LedPinB, OUTPUT);

pinMode(ButtonPinA, INPUT);

pinMode(ButtonPinB, INPUT);

}

void loop()

{

buttonStateA = digitalRead(ButtonPinA);

if (buttonStateA == HIGH && brightnessA != 255)

{

brightnessA ++;

}

if (buttonStateA == LOW && brightnessA != 0)

{

brightnessA --;

}

analogWrite(LedPinB, brightnessA);

Serial.print(brightnessA);

Serial.print(" ");

buttonStateB = digitalRead(ButtonPinB);

if (buttonStateB == HIGH && brightnessB != 0)

{

brightnessB --;

}

if (buttonStateB == LOW && brightnessB != 255)

{

brightnessB++;

}

analogWrite(LedPinA, brightnessB);

Serial.println(brightnessB);

delay(5);

}

Experiment Result

Wire it up as the above diagram and upload well the code to the board, then you can see one cap lights up while the other one is off.

When tilt these two caps towards the same side, one cap is gradually become bright, another bright cap is gradually off.

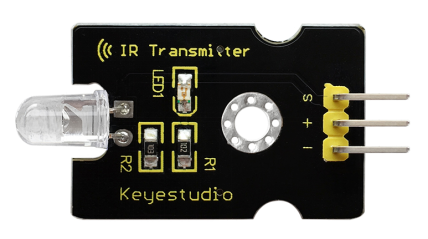

Project 26: Digital IR Transmitter

Introduction

IR Transmitter module is designed for IR communication which is widely used for operating the television device from a short line-of-sight distance. The remote control is usually contracted to remote.

Since infrared (IR) remote controls use light, they require line of sight to operate the destination device. The signal can, however, be reflected by mirrors, just like any other light source.

If operation is required where no line of sight is possible, for instance, when controlling equipment in another room or installed in a cabinet, many brands of IR extenders are available for this on the market. Most of these have an IR receiver, picking up the IR signal and relaying it via radio waves to the remote part, which has an IR transmitter mimicking the original IR control.

Infrared receivers also tend to have a more or less limited operating angle, which mainly depends on the optical characteristics of the phototransistor. However, it’s easy to increase the operating angle using a matte transparent object in front of the receiver.

Specification

- Power Supply: 3-5V

- Infrared center frequency: 850nm-940nm

- Infrared emission angle: about 20 degrees

- Infrared emission distance: about 1.3m (5V 38Khz)

- Interface: 3PIN

- Mounting hole: inner diameter is 3.2mm, spacing is 15mm

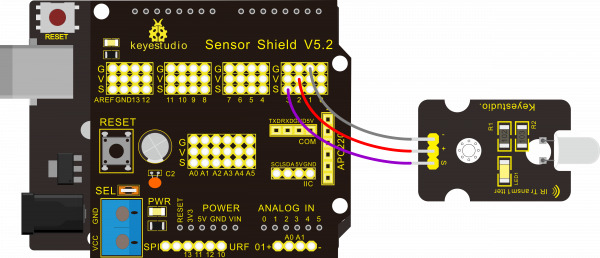

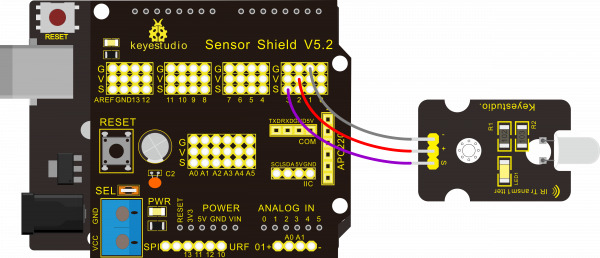

Hardware Connection

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- IR transmitter module*1

- USB Cable *1

- Jumper Wire *3

Connect the S pin to digital 3, negative pin to GND port, positive pin to 5V port.

Note: This IR transmitter module is not compatible with Mega2560 main board because IRremoteInt.h has no PWM port for _AVR_ATmega2560_device; but V4.0 is default using pin3

Sample Code

Copy and paste the code below to Arduino software.

int led = 3;

void setup() {

pinMode(led, OUTPUT);

}

void loop() {

digitalWrite(led, HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000); }

In the darkness of the environment, you are going to see blinking blue light on phone's screen when using camera to shoot the infrared LED.

Upload well the above code to the board, the led on the sensor will blink red light.

In the following, let’s move on to an interactive example between IR receiver and IR transmitter module.

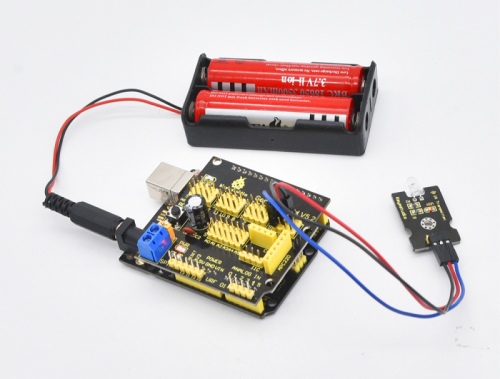

Infrared Remote/Communication

Hardware Required

- Arduino R3 x2

- Digital IR Receiver x1

- IR Transmitter Module x1

Note: here if you have no two main boards, you can replace it with the breadboard for connection, may be more easier and convenient.

- Get Arduino library Arduino-IRremote and install it

Connection Diagram

For IR Transmitter

Notice: Arduino-IRremote only supports D3 as transmitter.

For IR Receiver: connect the signal pin to D11 port.

Upload code to the V4.0 connected with IR Transmitter:

#include <IRremote.h>

IRsend irsend;

void setup()

{}

void loop() {

irsend.sendRC5(0x0, 8); //send 0x0 code (8 bits)

delay(200);

irsend.sendRC5(0x1, 8);

delay(200); }

Upload code to the V4.0 connected with IR Receiver:

#include <IRremote.h>

const int RECV_PIN = 11;

const int LED_PIN = 13;

IRrecv irrecv(RECV_PIN);

decode_results results;

void setup()

{Serial.begin(9600);

irrecv.enableIRIn(); // Start the receiver

}

void loop()

{if (irrecv.decode(&results))

{ if ( results.bits > 0 )

{

int state;

if ( 0x1 == results.value )

{

state = HIGH;

}

else

{

state = LOW;

}

digitalWrite( LED_PIN, state );

}

irrecv.resume(); // prepare to receive the next value

}}

Experiment Result

When IR Receiver module receives the infrared signal from IR Transmitter, D1 led on the IR Receiver module will blink. Shown as below figure.

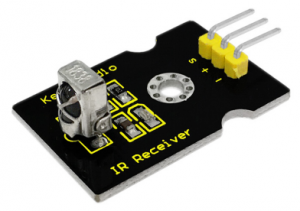

Project 27: Digital IR Receiver

Introduction

IR is widely used in remote control. With this IR receiver, Arduino Project is able to receive command from any IR remoter controller if you have the right decoder. Well, it will be also easy to make your own IR controller using IR transmitter.

Specification

- Power Supply: 5V

- Interface type: Digital

- Modulate Frequency: 38Khz

- Interface: 3PIN

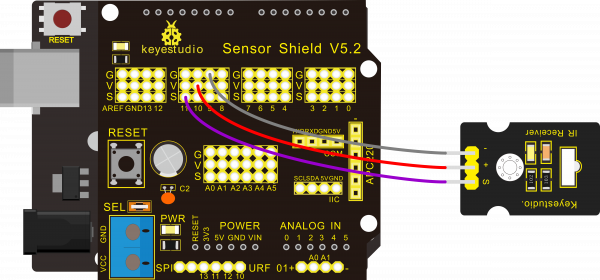

Wiring Diagram

To begin with, you need to prepare the following parts:

- Arduino Board *1

- keyestudio Sensor Shield V5* 1

- IR receiver module*1

- USB Cable *1

- Jumper Wire *3

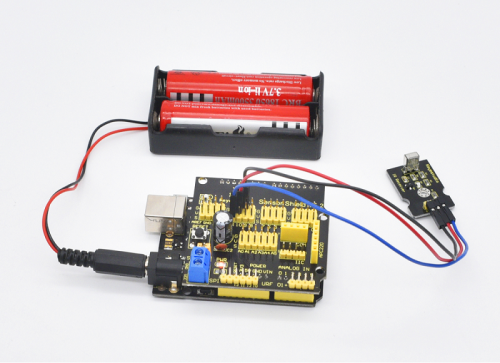

Connect the S pin to digital 11, negative pin to GND port, positive pin to 5V port.

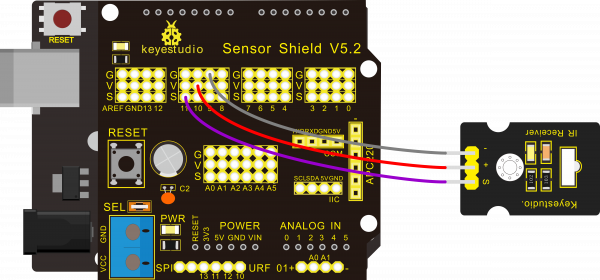

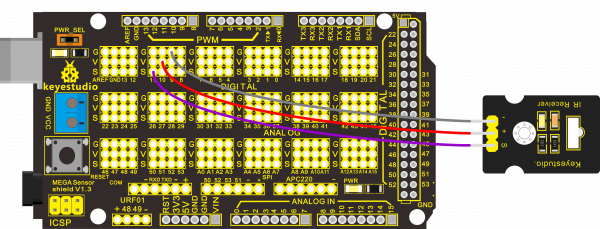

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Note: In the sample code below Digital pin 11 is in use, you may either change your wiring or change the sample code to match.

Sample Code

Copy and paste the code below to Arduino software.

#include <IRremote.h>

int RECV_PIN = 11;

IRrecv irrecv(RECV_PIN);

decode_results results;

void setup()

{

Serial.begin(9600);

irrecv.enableIRIn(); // Start the receiver

}

void loop() {

if (irrecv.decode(&results)) {

Serial.println(results.value, HEX);

irrecv.resume(); // Receive the next value

}

}

Note: before compiling the code, do remember to place the library into libraries directory of Arduino IDE. Otherwise, compiling will fail.

IR Remote Library includes some sample codes for sending and receiving.

https://github.com/shirriff/Arduino-IRremote

Experiment Result

Done wiring and uploading the code, then control the IR receiver module by an infrared remote control, D1 led will flash. Shown as below.

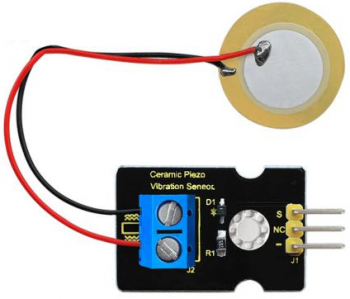

Project 28: Analog Ceramic Vibration

Description

This vibration sensor is based on piezoelectric ceramic chip analog vibration. It makes use of the anti-conversion process that piezoelectric ceramic vibration will generate the electric signals. When vibrating the piezoelectric ceramic chip, the sensor’s signal terminal will generate electrical signals.

The sensor can be used with Arduino dedicated sensor shield, and Arduino analog port can perceive weak vibration signals, so that it can make interactive works related to vibration, such as electronic drum.

Connect the vibration sensor to the analog port A0 of Arduino UNO. When vibrating the sensor in different degrees, you will see the different output value is displaying on serial monitor of Arduino software.

Specification

- Supply Voltage: 3.3V to 5V

- Working Current:<1mA

- Working Temperature Range:-10℃~+70℃

- Output Signal:analog signal

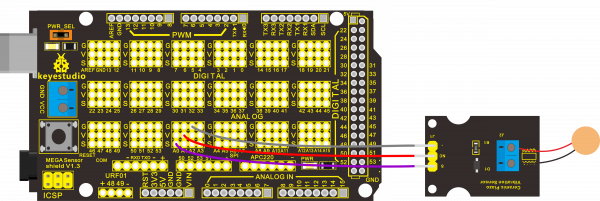

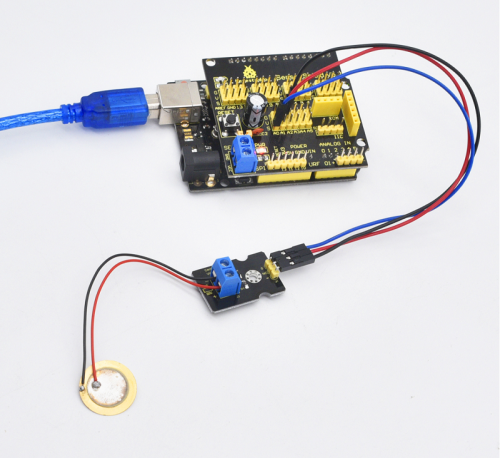

Connection Diagram

First, you need to prepare the following parts before connection:

- Arduino board*1

- keyestudio Sensor Shield V5* 1

- vibration sensor*1

- USB Cable*1

- Jumper wire*3

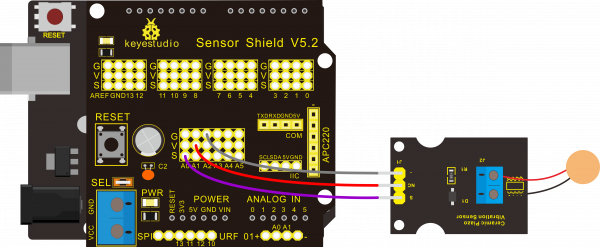

Connect the S pin to Analog A0, connect the negative pin to GND port, NC pin to 5V port.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

Copy and paste the below code to Arduino software.

void setup()

{

Serial.begin(9600); //Open the serial to set the baud rate as 9600bps

}

void loop()

{

int val;

val=analogRead(0); //Connect the sensor to analog interface A0

Serial.print("Vibration is ");

Serial.println(val,DEC);//Print the analog value read on serial port

delay(100);

}

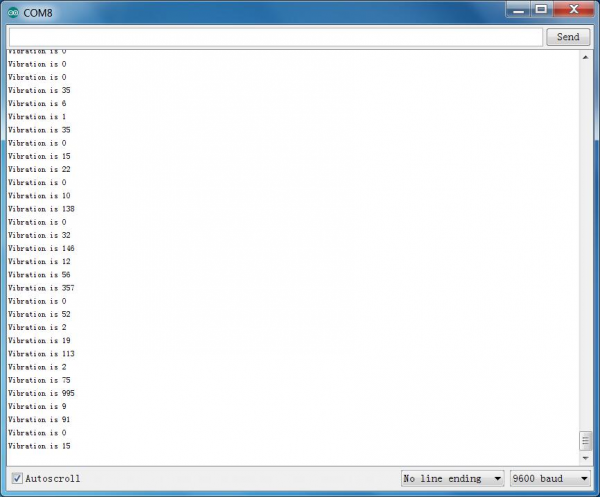

Experiment Result

Wiring as the above diagram and upload well the code, then open the serial monitor and set the baud rate to 9600.

When vibrating the ceramic chip, you will see the data change as the figure shown below.

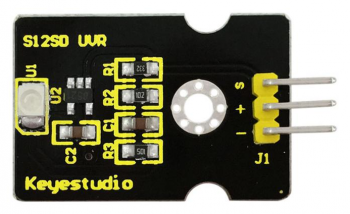

Project 29: Ultraviolet Light

Description

keyestudio GUVA-S12SD ultraviolet sensor is used to detect ultraviolet light.

It includes GUVA-S12SD applied to measure ultraviolet index of intelligent wearable device, such as watches, smart phone and outdoor device with UV index detecting.

It can be also used to monitor the intensity of ultraviolet light or used as a UV flame detector when disinfecting things by ultraviolet light.

Parameters

- Supply Voltage: 2.5V~5V

- Output Signal: Analog Signal

- Detecting Range of Spectrum: 240-370nm

- Active Region: 0.076mm2

- Responsivity: 0.14A/W

- Dark Current: 1nA

- Light Current: 101~125nA UVA Light, 1mW/cm2

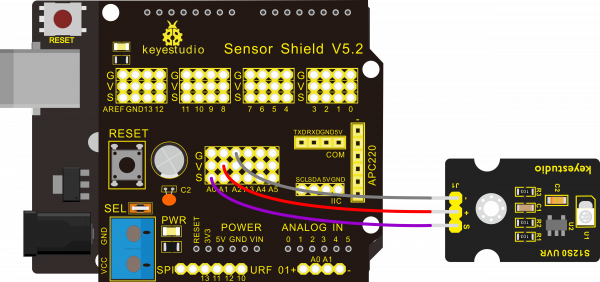

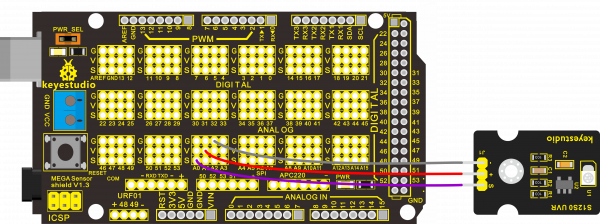

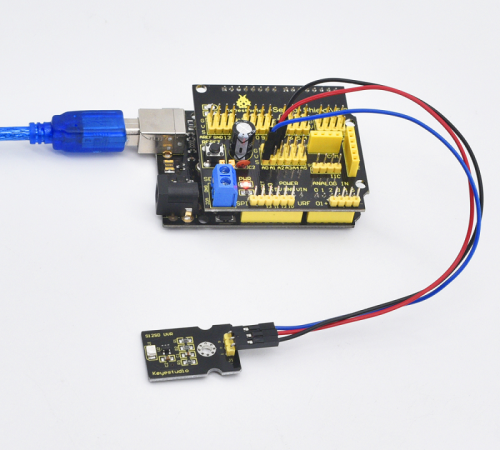

Connection Diagram

Firstly you need to prepare the following parts before connection.

- Arduino Board*1

- keyestudio Sensor Shield V5* 1

- Ultraviolet Sensor *1

- USB Cable*1

- Jumper Wire*3

Connect the S pin to Analog A0, connect the negative pin to GND port, positive pin to V pin.

For V4.0 connection:

Stack the Sensor Shield V5 onto the V4.0 board.

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board.

Sample Code

Copy and paste the code below to Arduino software.

/*

AnalogReadSerial

Reads an analog input on pin 0, prints the result to the serial monitor.

Attach the center pin of a potentiometer to pin A0, and the outside pins to +5V and ground.

This example code is in the public domain.

*/

// the setup routine runs once when you press reset:

void setup() {

// initialize serial communication at 9600 bits per second:

Serial.begin(9600);

}

// the loop routine runs over and over again forever:

void loop() {

// read the input on analog pin 0:

int sensorValue = analogRead(A0);

// print out the value you read:

Serial.println(sensorValue);

delay(1); // delay in between reads for stability

}

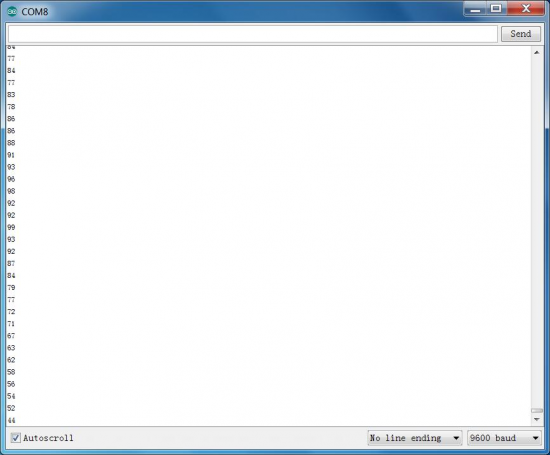

Experiment Result

Upload the program code, then open serial monitor, it will display the data.

If shine UV light to the sensor, the data on serial monitor is changing.

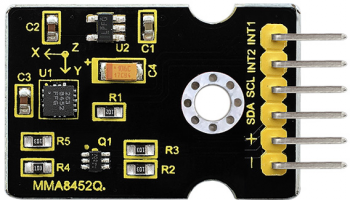

Project 30: Triaxial Digital Acceleration Detection

Introduction

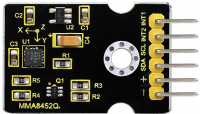

MMA8452Q is a smart low-power, three-axis, capacitive micromachine acceleration sensor with 12-bit resolution.

This acceleration sensor has a rich embedded performance, featured with flexible user programmable options and two interruption pins configuration. The embedded interruption function can save the overall power consumption and remove the burden of constantly polling the data in the main processor.

Besides, MMA8452Q has a user optional range of ±2g / ±4g/ ±8g, which can output high-pass filtering data and non-filtered data in real time.

This device can configure an embedded function to generate an inertial wake-up interrupt signal, which enables MMA8452Q to maintain a low-power mode in the static state while monitoring the event.

Performance Parameters

- Power Supply Voltage:DC 3.3 V to 5 V

- ±2g/±4g/±8g Optional dynamic range

- Output data rate (ODR) range: 1.56 Hz to 800 Hz

- Noise:99μg/√Hz

- 12 bits and 8 bits digital outputs;

- I2C digital output interface (up to 2.25 MHz when the pull-up resistor is 4.7 kΩ);

- Two programmable interruption pins applied to six interruption sources;

- Three motion detection embedded channels: free fall detection, pulse detection, shaking detection;

- Direction (transverse/longitudinal) detection with setting lag compensation;

- Automatic arousal and auto-dormant ODR can be automatically altered;

- High-pass filtering data can be exported in real time;

- Power consumption: 6 μA – 165 μA

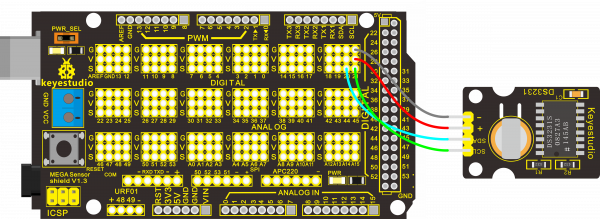

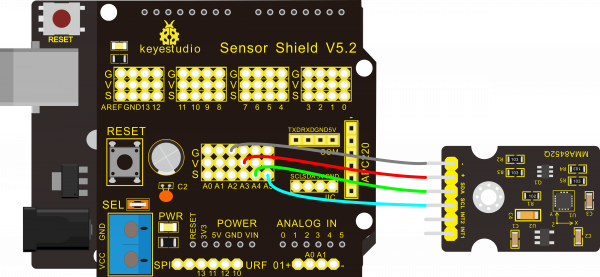

Connection Diagram

Firstly you need to prepare the following parts by yourself before testing.

- Arduino Board*1

- keyestudio Sensor Shield V5* 1

- MMA8452Q sensor*1

- USB Cable*1

- Jumper Wire*4

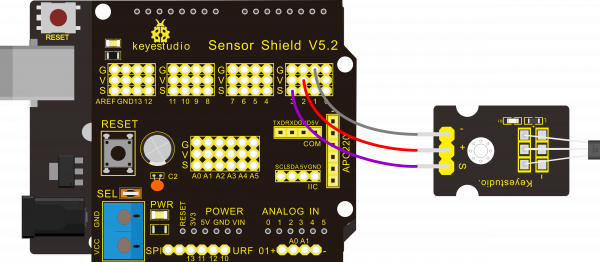

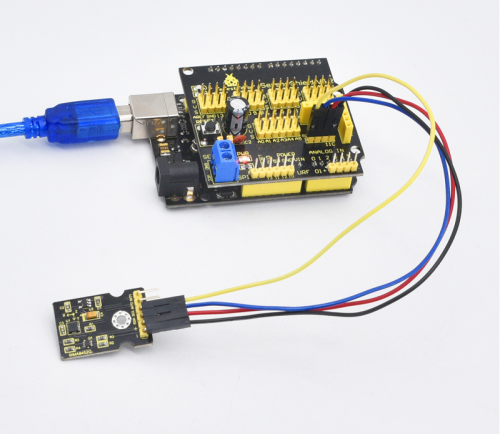

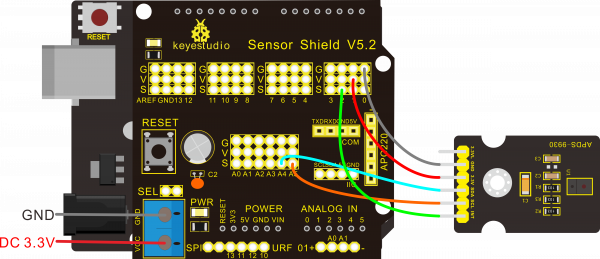

For V4.0 connection

Stack the Sensor Shield V5 onto the V4.0 board. Connect the SCL pin of MMA8452Q sensor to Analog A5, SDA pin to Analog A4; Connect positive pin (+)to V pin, negative pin(-) to GND.

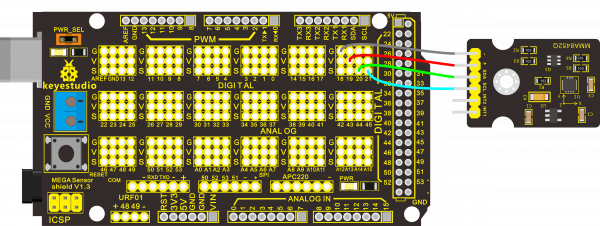

For 2560 R3 connection

Stack the Sensor Shield V5 onto the 2560 R3 board. Connect the SCL pin of MMA8452Q sensor to pin D21, SDA pin to pin D20; Connect positive pin (+)to V pin, negative pin(-) to GND.

Sample Code

Copy and paste the code below to Arduino software.

#include <Wire.h> // Must include Wire library for I2C

#include <SparkFun_MMA8452Q.h> // Includes the SFE_MMA8452Q library

// Begin using the library by creating an instance of the MMA8452Q

// class. We'll call it "accel". That's what we'll reference from

// here on out.

MMA8452Q accel;

// The setup function simply starts serial and initializes the

// accelerometer.

void setup()

{

Serial.begin(9600);

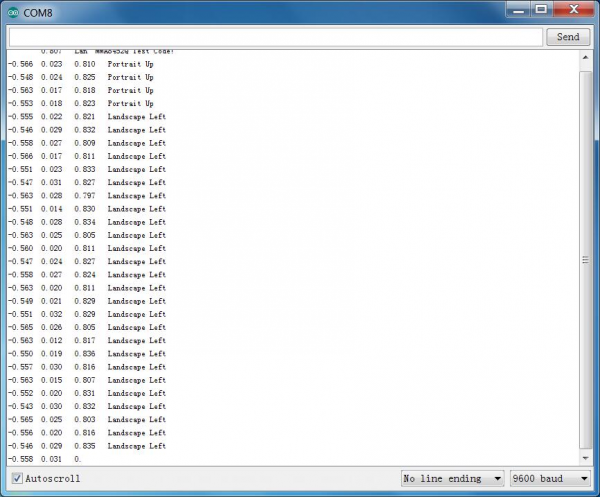

Serial.println("MMA8452Q Test Code!");

// Choose your adventure! There are a few options when it comes

// to initializing the MMA8452Q:

// 1. Default init. This will set the accelerometer up

// with a full-scale range of +/-2g, and an output data rate

// of 800 Hz (fastest).

accel.init();

// 2. Initialize with FULL-SCALE setting. You can set the scale

// using either SCALE_2G, SCALE_4G, or SCALE_8G as the value.

// That'll set the scale to +/-2g, 4g, or 8g respectively.

//accel.init(SCALE_4G); // Uncomment this out if you'd like

// 3. Initialize with FULL-SCALE and DATA RATE setting. If you

// want control over how fast your accelerometer produces

// data use one of the following options in the second param:

// ODR_800, ODR_400, ODR_200, ODR_100, ODR_50, ODR_12,

// ODR_6, or ODR_1.

// Sets to 800, 400, 200, 100, 50, 12.5, 6.25, or 1.56 Hz.

//accel.init(SCALE_8G, ODR_6);

}

// The loop function will simply check for new data from the

// accelerometer and print it out if it's available.

void loop()

{

// Use the accel.available() function to wait for new data

// from the accelerometer.

if (accel.available())

{

// First, use accel.read() to read the new variables:

accel.read();

// accel.read() will update two sets of variables.

// * int's x, y, and z will store the signed 12-bit values

// read out of the accelerometer.

// * floats cx, cy, and cz will store the calculated

// acceleration from those 12-bit values. These variables

// are in units of g's.

// Check the two function declarations below for an example

// of how to use these variables.

printCalculatedAccels();

//printAccels(); // Uncomment to print digital readings

// The library also supports the portrait/landscape detection

// of the MMA8452Q. Check out this function declaration for

// an example of how to use that.

printOrientation();

Serial.println(); // Print new line every time.

}

}

// The function demonstrates how to use the accel.x, accel.y and

// accel.z variables.

// Before using these variables you must call the accel.read()

// function!

void printAccels()

{

Serial.print(accel.x, 3);

Serial.print("\t");

Serial.print(accel.y, 3);

Serial.print("\t");

Serial.print(accel.z, 3);

Serial.print("\t");

}

// This function demonstrates how to use the accel.cx, accel.cy,

// and accel.cz variables.

// Before using these variables you must call the accel.read()

// function!

void printCalculatedAccels()

{

Serial.print(accel.cx, 3);

Serial.print("\t");

Serial.print(accel.cy, 3);

Serial.print("\t");

Serial.print(accel.cz, 3);

Serial.print("\t");

}

// This function demonstrates how to use the accel.readPL()

// function, which reads the portrait/landscape status of the

// sensor.

void printOrientation()

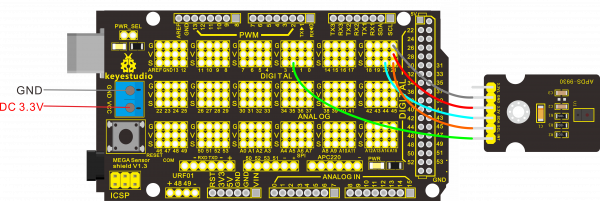

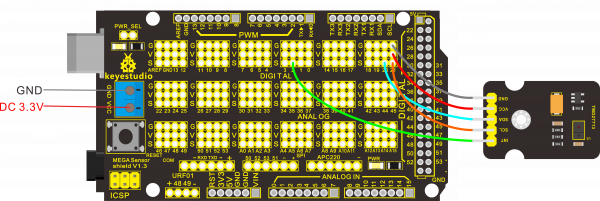

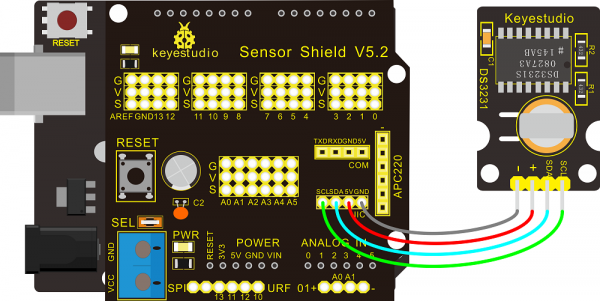

{